Home > Products > Surface Treatment > The Preparation of Anti-corrosion And Wear-resistant Tungsten Carbide Coating by Supersonic Spraying With Tension Rollers

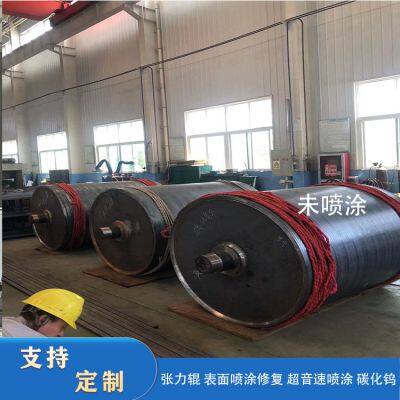

The Preparation of Anti-corrosion And Wear-resistant Tungsten Carbide Coating by Supersonic Spraying With Tension Rollers

- T/T L/C PayPal D/P Western Union Other

You May Like

-

Spraying on the Surface of the Arc-shaped Roller

-

Surface Spraying of the Spray-welding Roller

-

Preparation of Anti-corrosion And Wear-resistant Spray Welding Rollers

-

Papermaking Drying Cylinder

-

Papermaking Drying Cylinder Accessories And Papermaking Scraper Are Available in Various Models

-

Jinan Thermal Spraying Plasma Processing of Silicon Carbide Coating

Product Description

Application and Advantages of Metal Functional Coatings:

Wear-resistant coating: By adding a hard metal alloy coating, such as tungsten carbide or chromium alloy, to the surface of the tension roller, the wear resistance of the tension roller can be significantly improved and its service life can be prolonged.

2. Corrosion-resistant coating: In corrosive environments, using metal or alloy coatings with excellent corrosion resistance, such as nickel-based alloys and zinc-based alloys, can protect tension rollers from chemical erosion.

3. Low-friction coating: By using metal coatings with low friction performance, such as chromium plating and PVD titanium nitride coating, the friction between the tension roller and the material can be reduced, wear can be decreased, and production efficiency can be improved.

4. Anti-adhesion coating: For the production process of materials that are prone to adhesion, using metal coatings with anti-adhesion properties, such as polytetrafluoroethylene (PTFE) and siloxane, can prevent the material from adhering to the surface of the tension roller, ensuring the smooth progress of the production process.

5. Thermal stability coating: In high-temperature environments, by adding metal or alloy coatings with high thermal stability, such as nickel-chromium alloy, molybdenum alloy, etc., the thermal stability of tension rollers can be enhanced and thermal deformation can be prevented.

The application of thermal spraying technology on the surface of tension rollers has achieved remarkable results. For instance, in industries such as papermaking, textile, and plastic film, the preparation of metal functional coatings can effectively enhance production efficiency and reduce maintenance costs. With the continuous development of materials science and coating technology, more high-performance and multi-functional metal functional coatings will emerge in the future to meet the constantly changing demands in industrial production.

Contact Us

- Jinan Tianmen New Material Technology Co., Ltd

- Contact nameXue Yunling Chat Now

Product Categories

| Surface Treatment |

New Products

-

The Papermaking Drying Cylinder Is Coated With A Double-layer Tungsten Carbide + Teflon Coating for Anti-corrosion And Anti-adhesion

-

Surface Repair of the Rewinding Machine Roller

-

Supersonic Spraying for the Surface Treatment of the Shaft Seal Rotor

-

The Surface of the Impeller is Strengthened by Spraying

-

Machine Industry Fluidized Bed Thermal Spraying Processing Teflon Preparation Anti-corrosion Wear-resistant Can Support Customized

-

Surface Treatment of Filter Core Plate Using Plasma Technology for Corrosion Prevention, Wear Resistance, and High Temperature Resistance

-

Surface Treatment of Machinery Industry Thermal Spraying Plasma Process Anti-corrosion, Wear-resistant and Thermal Insulation

-

Surface Treatment in the Mechanical Industry, Spraying Tungsten Carbide for Corrosion Prevention and Wear Resistance

-

Directly Supplied by the Manufacturer for Laser Cladding Surface Treatment, Piston Rod Surface Repair, Anti-corrosion and Wear-resistant

-

Repair of the Surface of the Drying Cylinder by Spraying Tungsten Carbide+Teflon Anti-corrosion and Wear-resistant Non Stick Coating

-

Surface Repair of the Mechanical Industry, Multi Section Roller, Supersonic Spraying Processing, Tungsten Carbide Coating, Wear-resistant and Anti-corrosion

-

Boiler Surface Repair and Spraying of Nano Ceramic Coating for Anti-corrosion and Wear Prevention

-

Support Customized Mechanical Sliding Rails for Laser Melting Surface Repair, Anti-corrosion and Wear-resistant

-

Ceramic Coating Scraper, Coating Scraper, Paper Coating Roller and Other Mechanical Scraper Products

-

Surface Repair and Aluminum Spraying Treatment Process for Mechanical Valves in the Source Factory

-

Roller Surface Repair Using Spray Welding Process NI60 Coating Wear-resistant and Anti-corrosion Preparation

-

Mechanical Industry Supersonic Spray Machining Spiral Shaft Surface Repair, Spraying Anti-corrosion and Wear-resistant Coating

-

The Surface Repair of Stainless Steel Plates by the Manufacturer Adopts Arc Spraying Process LX88A Coating, Which is Super Hard and Wear-resistant

-

Surface Repair of Stainless Steel Plates in the Mechanical Industry, Arc Spraying, Wear Resistance and Corrosion Resistance

-

Thermal Spraying Processing Hopper Surface Repair Spraying Tungsten Carbide Coating for Anti-corrosion and Wear Resistance, With a Wide Range of Applications

-

Thermal Spraying Processing Hopper Surface Repair Arc Spraying Anti-corrosion and Wear-resistant With a Wide Range of Applications

-

Teflon Coated Coated Steel Products Coating Hardness Can be Adjusted Packaging Anti-collision

-

Arc Spraying Repair of GP-99 Coating on the Surface of Tianmeng Roller With Anti-corrosion and Wear-resistant Adjustable Coating Hardness

-

Metal Surface Treatment, Thermal Spraying, Tungsten Carbide Processing, Anti-corrosion and Wear-resistant for Tianmeng Wind Cap Disk

Popular Searches

- timing belt

- auto spare part

- taper roller bearing

- conveyor system

- conveyor equipment

- conveyor idler

- belt tensioner

- belt tensioner pulley

- belt conveyor roller

- extension spring

- tension spring

- elevator wheel

- tensioner pulley

- massage roller

- electrostatic separator

- tensioner bearing

- impact idler

- carrying roller

- conveyor trough roller

- carrying idler

- spiral torsion spring

- automatic tensioner

- milling cutter

- spray equipment

- turning insert

- milling tool

- ball nose end mill

- solid carbide end mill

- square end mill

- tungsten carbide insert

Recommended Products

- Heavy-Duty Automatic Wire Cutting Stripping Machine

- Automatic Wire Cutting Stripping and Twisting Machine

- Automatic Wire Cut Strip Twisting Machine

- Automatic Twin Flat Electric Cable Cutting Stripping Twisting Machine

- Automatic Sheathed Cable Cutting Sheath and Cores Stripping Machine

- Automatic Ribbon Cable Splitting Cutting Stripping Machine

- Automatic Multicore Cable Cutting Sheath & Cores Stripping Machine

- Automatic Multi-core Cable Cutting Stripping Machine

- Automatic Flat Sheathed Cable Cutting Stripping Machine

- Automatic Dual Parallel Wire Diff. Length-Cutting Stripping Splitting Machine

- Automatic Double Parallel Wire Cutting Stripping Splitting Machine

- Automatic Battery Cable Cutting Stripping Machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Xue Yunling

Hi there! Welcome to my shop. Let me know if you have any questions.

Xue Yunling

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile