Home > Products > Stainless Steel Sintered Production > Sintered stainless steel filters as carbonation stone for beer

Sintered stainless steel filters as carbonation stone for beer

- 100000 Piece / Pieces per Month

- Shanghai or Tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow

You May Like

Product Details

| Brand Name | TOPTITECH | Place of Origin | China |

Product Description

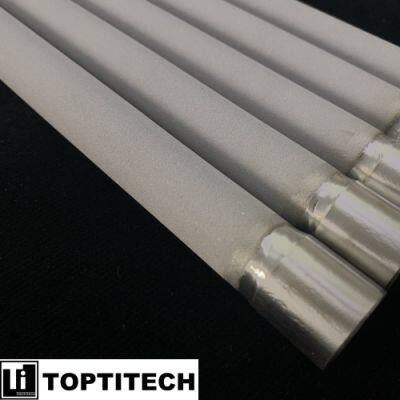

Sintered stainless steel filters as carbonation stone for beer

TOPTITECH stainless steel carbonation stones, not truly stones, are predominantly crafted from porous stainless steel 316L, also known as 'Air Stones'. These stones are commonly employed to aerate wort before fermentation, ensuring a robust start to the fermentation process. Constructed from top-tier food-grade stainless steel material 316L, TOPTITECH carbonation stones boast healthiness, practicality, durability, high-temperature resistance, and corrosion resistance. They offer easy cleaning and remain intact in beer or wort post-use.

These stainless steel carbonation stones from TOPTITECH are well-suited for force carbonating beer, making them an excellent choice for kegged beer carbonation or as an aeration stone pre-fermentation. Professionals use stainless steel carbonation stones to carbonate beverages such as beer, champagne, or sparkling meads with carbon dioxide. The micron stainless steel carbonating stone accelerates beer carbonation, producing a long-lasting head due to the creation of smaller bubbles. It rapidly infuses beer/soda water with CO2 or O2 by passing the gas through millions of tiny stone pores, effectively dissolving it into the liquid, enriching the mouthfeel of your beer or soda water.

Specification:

Material: stainless steel 316L

Pore size: 1um

External diameter: 20mm

Length: 270mm

Connection: 3/8" thread on both sides

Advantage:

1. Enhancing yeast health: By inserting the oxygenation wand into the fermenter and introducing thousands of minute oxygen bubbles for 1-2 minutes, yeast vitality increases, leading to the production of exceptional flavors and ensuring complete fermentation. Yeast thrives in an environment devoid of bacterial competition, ensuring both quality fermentation and a bacteria-free end product.

2. Enhanced Carbonation Control: Stainless steel filters provide brewers with precise control over the carbonation levels in beer, ensuring consistent quality and desired effervescence.

3. Enhanced Efficiency: Stainless steel filters used as carbonation stones offer enhanced efficiency in the carbonation process compared to traditional methods. The micro-pores in the stainless steel allow for a finer dispersion of carbon dioxide bubbles, resulting in more effective and controlled carbonation.

4. Consistent Carbonation: One of the key benefits of using stainless steel filters as carbonation stones is the ability to achieve consistent carbonation levels in every batch of beer produced. This consistency is crucial for maintaining the desired flavor profile and mouthfeel of the beer.

Working Principle of Stainless Steel Filters as Carbonation Stones:

The working principle of stainless steel filters used as carbonation stones is based on their ability to facilitate the controlled infusion of carbon dioxide (CO2) gas into beer or other carbonated beverages. Here's a detailed breakdown of how these filters operate:

1. Micro-Porous Structure:

Stainless steel filters designed as carbonation stones feature a fine and uniform micro-porous structure. These microscopic pores serve as channels for the passage of carbon dioxide gas from a pressurized source into the liquid.

2. Gas Diffusion:

When the carbonation stone is connected to a gas line carrying CO2, the gas is forced through the tiny pores of the stainless steel filter. The high pressure of the CO2 gas causes it to diffuse out of the pores in a dispersed and controlled manner.

3. Even Dispersion:

The fine pores in the stainless steel filter ensure that the carbon dioxide gas is evenly dispersed throughout the liquid, whether it be beer, cider, or other carbonated beverages. This uniform dispersion is crucial for achieving consistent carbonation levels.

4. Bubble Formation:

As the carbon dioxide gas escapes from the pores of the stainless steel filter, it forms tiny bubbles within the liquid. These bubbles gradually rise to the surface, dissolving into the liquid and creating the desired level of carbonation.

5. Controlled Carbonation:

Brewers can regulate the flow rate of CO2 gas and the duration of exposure to achieve the desired carbonation level in the beverage. By adjusting these parameters, brewers can tailor the carbonation process to meet specific taste preferences and style requirements.

Contact Us

- Baoji Yinggao Metal Materials Co., Ltd.

- Contact nameAna Chat Now

- Phone86-0917-3873009

- AddressWeibin, Baoji, Shaanxi

Product Categories

| porous titanium | Titanium Material | Titanium Process parts | Stainless Steel Sintered Production |

| Copper Sintering Material | sintered titanium product | other products |

New Products

-

GR1 Titanium Porous Sheet

-

GR1 Titanium Felt

-

Sintered Rupture Disks

-

Platinum-coated titanium anode

-

5-Layer Sintered Wire Mesh

-

Titanium anode (MMO)

-

5-Layer Sintered Wire Mesh

-

Sintered Wire Mesh

-

Titanium Filter Element

-

Titanium Anode For Water Treatment

-

Sintered Wire Mesh

-

5-Layer Sintered Wire Mesh

Popular Searches

- water treatment

- water purifier

- water filter

- filter cartridge

- air filter

- oil filter

- Filter Element

- wire mesh

- water filtration

- cartridge filter

- bag filter

- filter housing

- wire mesh filter

- Screen Filter

- filter mesh

- Sand Filter

- stainless steel strainer

- Coffee Filter

- Strainer Filter

- Y Strainer

- Candle Filter

- Mesh Filter

- filter valve

- sanitary filter

- sanitary strainer

- filter cylinder

- water filter

- water purification

- Water Treatment System

- water filter system

Recommended Products

- Supply German votech filter element model: DuoTOV 90/838

- Advantages of German Votech Filter Products

- Votech Filter Cartridge from Germany

- Advantageous supply of Votech filter cartridges and filters from Germany

- Supply Votech filter VPZ170/800 1.09

- VoTech Coalescing Filter Duotov 90/838

- High-Efficiency Spherical Powder Sintered Copper Fuel Filter

- BUSCH high quality exhaust filter 0532140160 suitable for R5 RA0400/0630 vacuum pump oil mist filter

- LVSHEN hot sale vacuum pump exhaust filter 0532140159 suitable for R5 Ra0302D

- LVSHEN high quality MS30 MS40+ 03.70437 rotary vane vacuum pump exhaust filter oil mist separator

- GR1 Titanium Filter Tube for Inline Diffuser

- 50 micron custom threaded SS316L powder sintered filter element

Find Similar Products By Category

- Industrial Equipment & Components > Filtration Equipment & Parts > Filter Element

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Ana

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Ana

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile