Home > Products > Stainless Steel Sintered Production > 5-Layer Sintered Wire Mesh

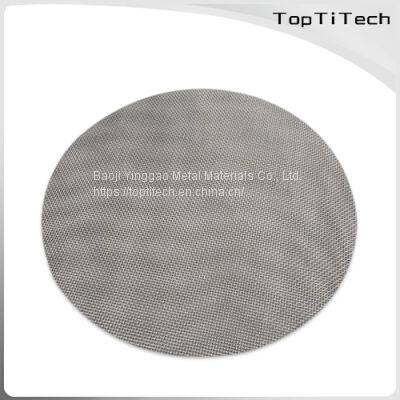

5-Layer Sintered Wire Mesh

- 10000 Piece / Pieces per Month

- shanghai

- T/T L/C

You May Like

Product Details

| Brand Name | Top Ti | Place of Origin | China | |

| Model Number | SS-001 | After-sales Service Provided | No overseas service provided |

Product Description

[5-layer sintered wire mesh] is produced by a vacuum sintering process, which has the characteristics of high-pressure resistance, uniform filtration aperture, and excellent corrosion resistance.

Porosity: 37%

Thickness: 1.7mm

Filtration accuracy: from 0.5 to 300μm.

Temperature: withstand -200°C-600°C.

Mesh size: 600*1200mm, 1200*1200mmas standard.

The protective layer, dispersion layer, filter control layer, support reinforcement layer, and reinforcement layer. Therefore, it can always achieve a higher filtration precision with 0.5-300μm and a longer service time than traditional wire mesh.

The 5 layers of sintered wire mesh can be reused and cleaned. After a period time of use, we recommend cleaning it by physical or chemical methods, such as backflushing or ultrasonic.

Contact us today for more information about 5-layer sintered wire mesh and an instant quote!

Specification

The 5 - layer sintered mesh is available in a variety of accepted standard sizes.

They include;

480 mm x 480 mm

480 mm x 980 mm

500 mm x 1000 mm

600 mm x 1200 mm

610 mm x 1219 mm

610 mm x 1250 mm

1000 mm x 1000 mm

1200 mm x 1200 mm

We can make the required size according to the customer's requirements.

Five-layer sintered materials are used in a variety of industries. Let's see what they are.

Powder industry

Mechanical industry

Steel industry

Electrical industry

Pharmaceutical industry

Chemical fiber film industry

Petrochemical industry

The applications of 5-layer sintered wire mesh:

Filtration and purification of polymer melts

Filtration of water

Filtration of chemicals

Production of sulfur plates

Gas homogenization

Filtration of hydraulic fuels

Sound splitters fabrication

Drying of several materials

Breather vents

Solid particles separation

Transpiration cooling in high-temperature situations

Used to limit current

The 5-layer sintered wire mesh has many benefits. So, let’s see what they are;

The 5 layers of sintered wire mesh will not rust.

It is widely used in bending, stretching, welding, punching, and cutting.

The 5-layer sintered mesh has a long service life.

The high viscosity and pressure environment do not limit the filtration performance of the 5-layer sintered wire mesh.

Because it has two protective layers, the filter does not deform.

5 layers of sintered wire mesh cleaning are very convenient.

Resist high temperatures.

You can customize 5 layers of sintered wire mesh to suit a variety of operating conditions.

The 5 - layer sintered wire mesh is very useful.

Contact Us

- Baoji Yinggao Metal Materials Co., Ltd.

- Contact nameAna Chat Now

- Phone86-0917-3873009

- AddressWeibin, Baoji, Shaanxi

Product Categories

| porous titanium | Titanium Material | Titanium Process parts | Stainless Steel Sintered Production |

| Copper Sintering Material | sintered titanium product | other products |

New Products

-

5-Layer Sintered Wire Mesh

-

Titanium anode (MMO)

-

5-Layer Sintered Wire Mesh

-

GR1 Titanium Felt

-

GR1 Titanium Felt

-

Platinum-coated titanium anode

-

GR1 Titanium Foil

-

microporous pure titanium aeration head

-

microporous pure titanium aeration head

-

Sintered Rupture Disks

-

5-Layer Sintered Wire Mesh

-

Titanium sintered porous plate

Popular Searches

- filter cartridge

- Filter Element

- wire mesh filter disc

- filter mesh

- Stainless Steel Filter

- metal filter

- Filter Tube

- sintered filter cartridge

- sintered wire mesh

- Candle Filter

- Filter Disc

- Hand Tool

- building material

- filter cartridge

- auto parts

- pipe fitting

- machinery part

- investment casting

- Filter Element

- Steel Pipe

- galvanized steel

- furniture hardware

- wire mesh filter disc

- Steel Strip

- steel plate

- steel sheet

- steel coil

- steel tube

- filter mesh

- seamless pipe

Recommended Products

- Sintered Porous Titanium PTL for Green Hydrogen PEMWE

- Submersible Macerator: Underwater Debris Cutting in Wastewater Systems

- Stainless Steel Non-Drum Grinder: Corrosion-Resistant for Hygienic Environments

- Low-Maintenance Macerator: Hassle-Free Operation in WWTPs

- Low-Noise Macerator: Quiet Operation in Urban Treatment Plants

- High-Torque Macerator: Tough Solids Grinding for Wastewater Plants

- High-Efficiency Macerator for Wastewater Treatment Plant Debris Removal

- Low-Maintenance single Grinder: Hassle-Free Upkeep

- Stainless Steel Non-Drum Grinder: Corrosion-Resistant for Hygienic Environments

- Swivel Fittings Thread Protective Caps Hydraulic Line Hose Ro Membrane End Caps

- Sintered Porous Titanium Plate Of PEM Water Electrolysis For H2 Production

- 10um Titanium Sintered Porous Filter Plate For Filtration And Separation

Find Similar Products By Category

- Industrial Equipment & Components > Filtration Equipment & Parts > Industrial Water Filter

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile