Product Description

I. Product Overview

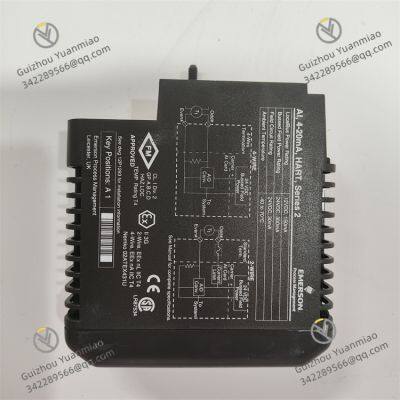

Emerson KJ4110X1-BA1 features a compact and robust housing structure, with its overall dimensions meticulously designed to be [specific dimension values] in length, width, and height respectively. This reasonable shape design enables it to flexibly adapt to various complex industrial installation environments. Whether it is inside a cramped control cabinet or a production site with strict requirements for equipment layout, it can easily find a suitable installation position without occupying excessive valuable space resources. Meanwhile, its shell is made of high-strength, corrosion-resistant high-quality materials, which can not only effectively resist physical damages such as collisions and friction that may be encountered in daily use but also have excellent dustproof and moisture-proof performance. It can operate stably for a long time in harsh industrial environments such as dusty and humid conditions, providing reliable physical protection and a stable working environment for the internal precision and complex electronic components.

This product integrates a series of advanced electronic components and a precisely optimized circuit layout. The selected electronic components are all from world-leading suppliers, and these components are renowned for their excellent performance such as high precision, low power consumption, and long service life, ensuring that the equipment always maintains a stable and reliable working state during long-term and high-intensity industrial operation. The circuit layout, which has undergone numerous simulation tests and actual verifications, can minimize signal interference, ensure the accuracy and integrity of data during transmission, and stably realize the processing and transmission of various signals even in complex electrical environments with strong electromagnetic interference, providing a solid hardware foundation for the stable operation of industrial automation systems.

II. Performance Parameters

(1) Communication Interfaces

Digital Communication Interface: Equipped with a high-speed RS-485 communication interface, which supports the standard Modbus RTU communication protocol and can achieve fast and stable data interaction with various devices that support the Modbus protocol. In industrial automation systems, through the RS-485 interface, KJ4110X1-BA1 can be conveniently connected to devices such as PLCs (Programmable Logic Controllers), intelligent sensors, and intelligent instruments, realizing information sharing and collaborative work between devices. Its communication rate can reach up to [specific high-speed rate value], which can meet application scenarios with high requirements for real-time data transmission, such as real-time monitoring and control of industrial production lines, and rapid collection and feedback of equipment status.

Analog Input and Output Interfaces: Has multiple high-precision analog input (AI) and analog output (AO) channels. The analog input channels can accurately collect various analog signals, such as voltage or current signals from pressure sensors, temperature sensors, flow sensors, etc. The input signal range covers common industrial standard ranges, such as 0-10V DC, 4-20mA, etc., with a resolution as high as [specific resolution value], which can accurately capture small changes in signals, providing reliable data support for precise monitoring of industrial processes. The analog output channels can output stable and accurate analog signals according to the instructions of the control system, which are used to control various actuators such as control valves and frequency converters. The accuracy and stability of the output signals also reach the industry-leading level, ensuring precise control of industrial processes.

(2) Signal Processing Capability

Data Acquisition and Conversion: In terms of data acquisition, KJ4110X1-BA1 has strong capabilities, being able to quickly and accurately collect signals from various sensors and convert them into digital signals for subsequent processing. Its built-in high-speed data acquisition module adopts advanced sampling technology, and the sampling rate can be flexibly configured according to actual application requirements, with a maximum of [specific sampling rate value] times per second, which can meet the real-time acquisition requirements of rapidly changing signals. At the same time, in the data conversion process, high-precision A/D (Analog/Digital) and D/A (Digital/Analog) converters are used to ensure minimal precision loss during signal conversion, effectively guaranteeing the accuracy and reliability of data.

Signal Processing Algorithms: To further improve the efficiency and quality of signal processing, KJ4110X1-BA1 has built-in a variety of advanced signal processing algorithms. These algorithms can perform processing such as filtering, denoising, and linearization on the collected data, effectively removing interference noise in the signals and improving the stability and reliability of the signals. For example, when processing temperature sensor signals, the use of digital filtering algorithms can effectively eliminate the impact of environmental noise on temperature measurement values, making the measurement results more accurate and stable. At the same time, for some non-linear sensor signals, through the built-in linearization algorithm, they can be converted into linear signals, facilitating unified processing and analysis by the control system, which greatly improves the control accuracy and response speed of the industrial automation system.

(3) Power Supply Characteristics

Power Input: Adopts 24V DC power supply. This common DC power supply specification is widely used in the industrial field, with advantages such as high stability and strong anti-interference ability, which can provide stable and reliable power support for KJ4110X1-BA1, ensuring that it can operate normally in various complex industrial environments. The power input port has good electrical isolation and overvoltage and overcurrent protection functions. When there is an abnormal fluctuation in the power supply, such as excessive voltage or current, it can automatically cut off the power input to protect the internal circuit of the device from damage, greatly improving the safety and reliability of the device and effectively reducing the risk of device damage or system failure caused by power supply faults.

Power Consumption: In terms of power consumption, KJ4110X1-BA1 has low power consumption through careful circuit design and optimization. In normal working conditions, its power consumption is only [specific power consumption value] W. This low-power characteristic not only helps reduce the overall energy consumption of the industrial automation system but also reduces the heat generation of the device during operation, improving the stability and service life of the device. Especially in some industrial application scenarios with strict requirements on energy consumption, such as energy management systems and green factory construction, the low-power advantage of KJ4110X1-BA1 is particularly prominent.

(4) Adaptability to Working Environment

Temperature Range: This product has an extremely wide working temperature range and can work normally in extreme temperature environments from -40°C to 70°C. This enables it to adapt to various different industrial application scenarios, whether it is oil extraction facilities in the cold Arctic region or chemical production installations in hot desert areas, it can operate stably without being affected by temperature changes in terms of performance and reliability. For example, in some outdoor industrial equipment, such as monitoring systems of wind farms and control systems of solar power stations, which often face drastic temperature changes, the wide temperature working range characteristic of KJ4110X1-BA1 makes it an ideal choice for signal processing and communication of these devices.

Protection Level: The protection level of KJ4110X1-BA1 reaches IP65, which means it has excellent dustproof and water splashing resistance capabilities. In dusty industrial production environments, such as cement plants, mines, steel mills, etc., it can effectively prevent dust from entering the interior of the device, avoiding faults such as short circuits and poor contact of electronic components caused by dust accumulation, and ensuring the long-term stable operation of the device. At the same time, in environments with water splashing, such as food processing workshops, car washes, ships, etc., it can also work reliably without being damaged by water splashing, providing a solid guarantee for the stable operation of the device in complex industrial environments.

(5) Configuration and Management

Configuration Methods: Emerson provides a variety of convenient configuration methods for KJ4110X1-BA1. Users can not only perform intuitive and convenient parameter settings on the PC side through dedicated configuration software, such as setting parameters of communication interfaces, signal processing algorithms, ranges of analog input and output, etc. The software has a simple and easy-to-use graphical user interface, so even ordinary users without profound professional knowledge can easily get started and quickly complete the configuration of the device; they can also perform on-site configuration through the buttons and display screen of the device itself. In some scenarios where it is inconvenient to use the PC side, this on-site configuration method is particularly practical. In addition, the device also supports remote configuration function, and users can remotely connect to the device through the network to adjust and configure its parameters, which greatly improves the management efficiency and flexibility of the device.

Status Monitoring and Diagnosis: KJ4110X1-BA1 has complete status monitoring and diagnosis functions. The device has multiple built-in sensors, which can real-time monitor its own working status, such as power status, communication status, signal processing status, etc., and feed back these status information to users through various means such as LED indicators, display screens, and remote communication interfaces. When the device fails, it can quickly perform fault diagnosis and provide detailed fault codes and prompt information, helping users quickly locate the cause of the fault and take corresponding solutions, effectively improving the maintenance convenience and fault troubleshooting efficiency of the device, reducing equipment downtime, and ensuring the continuous and stable operation of the industrial automation system.

III. Application Scenarios

(1) Industrial Automation Production Lines

Modern industrial automation production lines usually involve a large number of different types of equipment and complex process flows, requiring precise collection, processing, and transmission of various signals. KJ4110X1-BA1, with its powerful communication interfaces, excellent signal processing capabilities, and outstanding environmental adaptability, has become a key device in industrial automation production lines. For example, in automobile manufacturing production lines, it can be connected to various sensors, such as weld seam sensors for detecting the welding quality of car bodies, position sensors for controlling the actions of assembly robots, various pressure and temperature sensors for monitoring the operation status of the production line, etc., to collect signals from these sensors in real-time and transmit the processed data to the PLC control system, realizing precise control and real-time monitoring of the production line, ensuring efficient, stable, and reliable quality of the automobile production process.

(2) Process Control Systems

In process control industries such as chemical engineering, petroleum, and natural gas, there are extremely high requirements for the safety, stability, and accuracy of the production process. KJ4110X1-BA1 plays an important role in these fields. It can be connected to various on-site instruments, such as flow meters, level meters, analyzers, etc., to collect various process parameters in the production process and transmit these parameters to the control system for analysis and processing. At the same time, according to the instructions of the control system, it can also output corresponding control signals to precisely control actuators such as control valves and pumps, realizing optimal control of the production process. For example, in the control process of distillation towers in chemical production, through the precise collection and control of parameters such as top temperature, bottom level, and feed flow of the distillation tower by KJ4110X1-BA1, the stable operation of the distillation tower can be ensured, the product quality and production efficiency can be improved, and energy consumption and production costs can be reduced.

ABB 1MRB150051R1 Power Supply Module

ABB PPD513A-23-111615 magnetic excitation controller

TRICONEX Safety Instrumented System (SIS) 4351B control module

Bentley Nevada 3500/22M Transient data interface module

Bently Nevada 3500/15-05-05-00 power module

Triconex 3009 processor module

ABB GFD563A102 3BHE046836R0102 Excitation Convection Interface Module

ABB PPD117A3011 3BHE030410R3011 Excitation Controller

ABB PCD231B101 3BHE025541R0101 Excitation Unit Controller

ABB 5SHY3545L0010 3BHE009681R0101 High-Voltage Thyristor Module

ABB PCD230A 3BHE022291R0101 Controller Module

ABB 5SHY3545L0009 3BHB013085R0001 IGBT Module

Bently Nevada 3500/25 enhanced key phase module

Bently Nevada 3500/32 4-channel relay module

ABB PCD232A 3BHE022293R0101 Exciter Control Module

Bently Nevada 3500 monitoring system series modules

Bently Nevada 3500/33 relay module

ABB PCD235A101 3BHE032025R0101 Excitation Control Module

ABB PCD235C101 3BHE057901R0101 Excitation Unit Controller

Bently Nevada 3500/34 Triple redundant relay module

ABB PCD530A102 3BHE041343R0102 Controller

ABB PPD113B01-10-150000 3BHR023784R1023 Controller Module

ABB PPD512A10-150000 3BHE040375R1023 Excitation Controller

Bently Nevada 3500/40 monitor module

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.