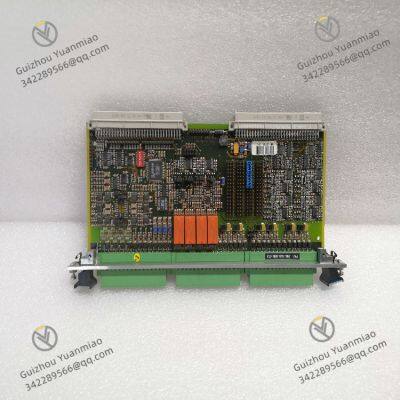

Product Description

Vibro-Meter 200-560-000-018 200-560-101-015 VM600 IOC4T is an input/output module that plays a key role in the field of industrial equipment condition monitoring. It belongs to the VM600 system family of Vibro-Meter company. With its excellent performance, reliable quality and outstanding compatibility, it guarantees the stable operation of various industrial machinery and helps enterprises achieve efficient production and precise equipment management.

I. Core Functions

(1) Accurate Signal Transmission and Preprocessing

Multi-channel data access: The IOC4T module is equipped with abundant input channels. Specifically, it supports 4 dynamic channels and 2 speed (tachometer) channels. Each channel can be independently configured and can connect multiple vibration sensors, speed sensors and other devices at the same time. In the monitoring scenario of large motor units, vibration sensors at parts such as motor bearing housings and shaft extensions, as well as motor speed sensors can be connected through different channels to comprehensively collect key data of equipment operation, providing detailed basis for subsequent state analysis.

Signal conditioning and transmission: For each dynamic channel and speed channel, the module has a differential signal input function, which can effectively suppress common-mode interference, ensuring that weak signals collected by sensors can be accurately transmitted to subsequent processing units in complex electromagnetic environments. At the same time, it also provides stable power output for sensors to ensure their normal operation. For example, in the monitoring of rolling mills in steel plants, even if there are a large number of strong electromagnetic interference sources on site, the IOC4T module can reliably obtain vibration and speed signals of equipment such as rolls and motors. In addition, each dynamic channel is also equipped with a differential buffered (original) sensor output, facilitating further analysis or backup of the original signal.

Signal conversion and output: The module integrates advanced signal conversion circuits. For dynamic signals, with the help of four on-board digital-to-analog converters (DACs), it can provide calibrated 0 to 10V voltage signal output; in addition, through four on-board voltage-current converters, the signal can be converted into 4 to 20mA current signal output (flexibly selectable through jumpers). This diversified form of signal output can adapt to different types of control systems and data acquisition equipment, greatly improving the compatibility and flexibility of the system.

(2) Equipment Condition Monitoring and Alarm

Local relay control: The IOC4T module is equipped with four local relays. Under the precise control of software, these relays can be associated with any specific alarm signal. In typical applications, they can be used to indicate faults in the MPC4 module or respond to problems detected by common alarms (such as sensor normal, early warning and danger signals). For example, when the monitoring system detects that the vibration amplitude of the equipment exceeds the normal range and reaches the early warning threshold, the corresponding relay can act quickly, triggering an acousto-optic alarm device by controlling the external circuit, and timely reminding operators to pay attention to the equipment status.

Digital signal transmission and expansion: The module can transmit 32 digital signals representing alarm status to the rack backplane. These signals can be utilized by optional RLC 16 relay cards and/or IRC 4 intelligent relay cards installed on the rack (selected through jumpers), thereby realizing further expansion and processing of alarm signals. In large automated production lines, equipment alarm information can be quickly transmitted to the central control system in this way, facilitating centralized management and unified scheduling, and timely taking corresponding measures to deal with equipment failures, reducing production losses.

(3) Efficient System Communication and Integration

Master-slave mode communication: The IOC4T module works in slave mode and communicates with the MPC4 module at high speed and stably through connector P2 using the industry-standard Industry Pack (IP) interface. In the VM600 system, they work closely together. The IOC4T is responsible for front-end signal collection, preprocessing and output, while the MPC4 focuses on in-depth analysis and processing of these signals. They cooperate with each other to ensure the efficient operation of the entire system.

Standardized interface design: Its front panel (i.e., the rear of the VM600 rack) is equipped with terminal connectors for connecting transmission cables from the measurement chain (sensors and/or signal conditioners). At the same time, these screw terminal connectors are also used for input and output of all signals with any external control system. This standardized interface design enables the IOC4T module to be easily integrated into various industrial automation systems. Whether it is a new monitoring project or the upgrading and transformation of an existing system, it can achieve rapid integration, reducing the cost of system construction and debugging.

II. Hardware Characteristics

(1) Rugged Industrial-grade Construction

Wide temperature adaptability: It is meticulously built with industrial-grade components and can operate stably in a relatively wide temperature range, with an operating temperature range of -20°C to +85°C. Whether it is the monitoring of wind power generation equipment outdoors in cold regions or the monitoring of furnace equipment in metallurgical workshops in high-temperature environments, it can cope with ease, ensuring that vibration and speed monitoring work is not affected by changes in ambient temperature, and providing continuous guarantee for the reliable operation of equipment.

High protection and anti-interference performance: It has excellent dustproof and moisture-proof performance, with a protection level in line with relevant industrial standards, and can work normally in harsh industrial environments such as dusty and humid conditions. At the same time, it performs excellently in anti-electromagnetic interference, and can effectively resist complex electromagnetic noise interference in industrial sites, such as strong electromagnetic interference generated by frequency converters, electric welders and other equipment, ensuring that the collected and transmitted signals are accurate and stable, and avoiding data errors or equipment misoperation caused by interference.

Shock and vibration resistance design: Considering the possible mechanical vibration and impact in industrial sites, the IOC4T module is fully optimized in structural design, adopting shock-resistant and impact-resistant layouts and fixing methods. Internal electronic components are also strictly screened and reinforced, ensuring that the module can still work stably under conditions such as equipment vibration and transportation bumps, and guaranteeing the continuity and reliability of monitoring data.

(2) Compact Structure and Convenient Installation

Modular compact layout: The IOC4T module adopts a modular design concept, with an overall compact structure and small size. Taking common dimensions as an example, its external dimensions may only be (length) 100mm x (width) 50mm x (height) 30mm, and the weight is light, about 100g. This compact design gives it great advantages when installed in equipment control cabinets or monitoring sites with limited space. It can be flexibly installed near key parts of the equipment, reducing the length of signal transmission lines, lowering signal transmission loss, and improving signal transmission quality.

Standardized installation interfaces: Equipped with standardized installation interfaces and terminals, the installation process is simple and convenient. According to the detailed installation manual, technicians can quickly complete the installation of the module on the VM600 rack and the wiring work with other equipment. When modifying on-site equipment or adding new monitoring points, it can greatly shorten the installation and debugging time, improve work efficiency, reduce installation costs, and save valuable human and time resources for enterprises.

Plug-and-play and hot-swap functions: It supports plug-and-play function. During system initialization, it can automatically identify and configure relevant parameters, reducing manual intervention and improving system startup speed. At the same time, some models also have hot-swap function. During system operation, the module can be directly plugged and replaced without shutting down the entire system, which greatly facilitates equipment maintenance and upgrading, and reduces production losses caused by shutdown maintenance.

(3) Stable and Reliable Power Supply

Wide-voltage DC power supply: It supports 24V DC power supply and has a certain wide-voltage adaptability, which can maintain stable operation within a certain voltage fluctuation range. In industrial sites, there are sometimes voltage instabilities in power supply. This feature of the IOC4T module can ensure that it can still operate normally when the power supply fluctuates, ensuring the continuity of vibration and speed monitoring work, and avoiding data loss or monitoring interruption due to power problems.

Comprehensive power protection mechanism: It has overvoltage, overcurrent and short-circuit protection functions. When there is an abnormal power supply, it can quickly and automatically cut off the abnormal power supply, effectively protecting the internal circuit of the module from damage. In extreme cases such as wrong power wiring or instantaneous impact of external power supply, it can prevent the module from being burned due to power failure, improve the safety and reliability of the equipment, extend the service life of the module, and reduce the equipment maintenance cost of enterprises.

III. Application Fields

(1) Energy and Power Industry

Power generation equipment monitoring: In the field of thermal power generation, it can be used to monitor the vibration and speed status of key equipment such as steam turbines and generators. By real-time monitoring the vibration of steam turbine blades and the speed fluctuation of generator rotors, potential fault hidden dangers of equipment, such as blade fatigue cracks and rotor imbalance, can be found in time, ensuring the safe and stable operation of power generation equipment, improving power generation efficiency, and reducing downtime and economic losses caused by equipment failures. In hydropower generation, monitoring the vibration and speed of water turbines is also crucial. The IOC4T module can help timely grasp the operating status of water turbines, ensuring the stable and efficient hydropower generation process. In terms of wind power generation, it can monitor the vibration of parts such as wind turbine main shafts and gearboxes, as well as the speed of wind turbines, providing strong data support for the reliable operation and preventive maintenance of wind turbines.

Transmission and distribution equipment monitoring: For transmission and distribution equipment such as transformers and high-voltage switches, the IOC4T module can assist in judging the operating status of the equipment by monitoring its vibration characteristics. For example, problems such as loose iron cores inside transformers and poor contact of high-voltage switch contacts will be reflected in the equipment vibration signals. Through real-time monitoring and analysis of these vibration signals, equipment failures can be warned in advance, ensuring the reliability and stability of power transmission and the safe operation of the power grid.

(2) Petrochemical Industry

Monitoring of key equipment in production installations: In production installations such as petroleum refining and chemical synthesis, key equipment such as compressors, pumps and centrifuges are prone to mechanical failures during long-term high-load operation. The IOC4T module can real-time monitor the vibration and speed of these equipment, timely find abnormal vibrations of the equipment, such as compressor surge, pump cavitation, centrifuge imbalance and other problems, take maintenance measures in advance, prevent production accidents caused by equipment failures, ensure the continuity and safety of the chemical production process, and avoid production stagnation and product quality decline caused by equipment failures.

Pipeline system vibration monitoring: During the operation of chemical pipeline systems, abnormal vibrations may occur due to fluid impact, pipeline resonance and other reasons. The IOC4T module can be used to monitor the vibration status of pipelines, timely find potential safety hazards such as pipeline rupture and leakage, ensure the safe operation of chemical pipeline systems, avoid environmental pollution and production accidents caused by pipeline failures, and ensure the safe production and sustainable development of chemical enterprises.

GE D20 EME Ethernet/Memory Board D20EME

Vibro-meter 200-560-000-113 200-560-101-017 VM600 IOC4T Input/Output Card

Vibro-meter 200-566-000-012 200-566-101-012 VM600 IOCN Interface Module

GE WES5123-2600 Field controller master unit

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Monitoring Module

Vibro-meter VM600?200-560-000-114?200-560-101-018?IOC4T Key Input/Output Control Module

GE WES5123-1200 Remote Terminal Unit

Vibro-meter 200-582-500-021 VM600 RPS6U SIM-330A Power Supply

Vibro-meter SIM-275A 200-582-500-013 Power Supply

VIBRO-METER VM600 RPS6U 200-582-500-013 Rack Power Supply

Vibro-meter VM600 RPS6U 200-582-200-011 Power Supply

Vibro-meter 200-595-031-111 VM600 CPUM Input/Output Communications Network Card

VIBRO-METER 200-595-100-014 200-595-072-122 VM600 CPUM CPU Board

VIBRO-METER 600-003 620-001-001-116 VM600 XMV16 Regulator Module

VIBRO-METER 620-002-000-113 620-003-111-112 VM600 XIO16T Communication Interface Card

Vibro-meter MPC4 200-510-078-115 Machinery Protection Card

Vibro-meter VM600 MPC4 200-510-064-034 200-610-100-034 Machinery Protection Card

GE IS420YDIAS1B Discrete Output I/O Pack

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.