Product Description

Vibro-meter 200-595-031-111 VM600 CPUM, as the core processing module of the VM600 system, is the "brain" of the entire industrial equipment condition monitoring system. With its powerful data processing capability, efficient system collaboration ability and reliable operation performance, it conducts in-depth analysis and integration of various monitoring data, provides accurate basis for equipment status evaluation and fault diagnosis, and plays an irreplaceable role in ensuring the safe and stable operation of industrial equipment.

I. Core Functions

(1) Efficient Data Processing and Analysis

Multi-source data integration: The CPUM module can receive massive amounts of data from various monitoring modules in the system (such as IOC4T input/output control module, vibration monitoring module, speed monitoring module, etc.), including vibration signals, speed, temperature, pressure and other parameters. Through the internal high-speed data bus, it realizes the rapid integration of these multi-source heterogeneous data, laying a foundation for subsequent analysis and processing. In the monitoring of large turbo-generator sets, it can simultaneously receive data from multiple monitoring points such as turbine bearing vibration, generator stator temperature, and steam pressure, and perform unified processing.

Real-time data analysis: Equipped with a high-performance processor, it has strong real-time data processing capability and can instantly analyze the collected raw data. It can calculate key indicators such as peak-to-peak value, effective value, and spectral characteristics of vibration, and dynamically track the operating trend of the equipment. For example, in fan monitoring, it can real-time analyze the vibration spectrum of fan blades, quickly identify fault characteristics such as blade imbalance and looseness, and provide support for timely early warning.

Operation of complex algorithms: It has built-in a variety of advanced fault diagnosis algorithms, such as wavelet analysis, neural network, Fourier transform, etc., which can conduct in-depth mining of complex monitoring data. Through these algorithms, it can accurately identify early fault patterns of equipment, such as bearing wear and poor gear meshing. In the compressor monitoring system, these algorithms can be used to extract weak fault characteristics from vibration signals, realize early warning of faults, and avoid sudden damage to equipment.

(2) System Collaboration and Control

Module collaborative management: As the core of the system, the CPUM module can uniformly manage and coordinate other modules in the VM600 system. Through standardized communication interfaces, it sends control commands to each monitoring module, configures their working parameters (such as sampling frequency, alarm threshold, etc.), and receives the working status information of each module to ensure the orderly operation of the entire system. In the production line equipment monitoring system, it can uniformly allocate the sampling cycle of each monitoring module to ensure the synchronization of data collection.

Alarm and control linkage: Based on the data analysis results, when it is found that the equipment parameters exceed the preset threshold, the CPUM module can quickly issue an alarm command and link relevant execution modules to take control measures. For example, in the monitoring of chemical reaction kettles, if the temperature in the reaction kettle is detected to be too high, it can immediately send a command to the control module to start the cooling system, and at the same time trigger an audible and visual alarm to remind operators to handle it.

Data storage and traceback: It has a large-capacity data storage function, which can store historical monitoring data, alarm records and other information of the equipment for a long time. It supports quick query and traceback of data, which is convenient for operators to analyze the operating history of the equipment, summarize fault rules, and optimize equipment maintenance strategies. In the monitoring of water turbines, by tracing back historical data, the changes in the operating status of water turbines under different seasons and different loads can be analyzed, providing data support for the formulation of equipment overhaul plans.

(3) Communication and Data Interaction

Support for multiple communication protocols: It supports multiple mainstream industrial communication protocols such as Ethernet/IP, Modbus TCP, and Profinet, and can seamlessly connect with the factory's upper-level systems such as DCS and SCADA to realize real-time upload and sharing of data. In smart factories, the monitoring data of equipment can be uploaded to the factory management platform to provide a basis for production scheduling and equipment management decisions.

Remote communication function: It has remote communication capability and can realize data interaction with the remote monitoring center through the network. Operators in the remote monitoring center can real-time check the operating status of the equipment, receive alarm information, and configure parameters of the CPUM module. This function can greatly reduce the on-site inspection workload and improve operation and maintenance efficiency in distributed industrial sites such as oil and gas pipeline monitoring.

Data encryption and security: Advanced data encryption technology is adopted to ensure the security of data during transmission and storage, preventing data leakage or tampering. In monitoring systems involving important industrial facilities (such as nuclear power plants, large chemical enterprises), data security is crucial, and this function can effectively ensure the information security of the monitoring system.

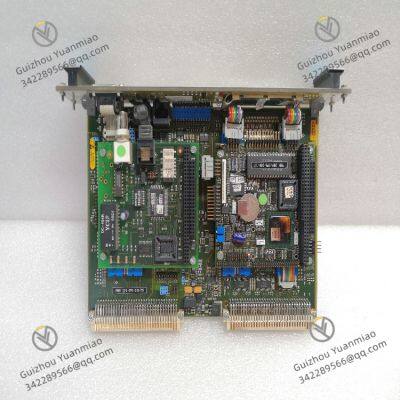

II. Hardware Characteristics

(1) Industrial-grade Reliable Design

Stable operation in a wide temperature range: Using industrial-grade components and optimized heat dissipation design, it can work stably in a wide temperature range of -20℃ to +70℃. Whether in cold northern mining areas or high-temperature southern steel plants, it can ensure the normal operation of the module and the continuity of the monitoring system.

Strong anti-interference ability: It has excellent electromagnetic compatibility, and can effectively resist electromagnetic interference, radio frequency interference, etc. in industrial sites through multiple shielding, filtering and other technologies. In industrial environments with a large number of motors and frequency converters, it can ensure the stability of data transmission and processing, and avoid data distortion or system failure caused by interference.

High-reliability structure: It adopts a robust shell design with a protection level of IP20, which can effectively prevent dust, water vapor, etc. from affecting the internal circuit. At the same time, the key components of the module adopt redundant design, which further improves the reliability of the system and reduces the failure rate.

(2) Compact Structure and Convenient Maintenance

Modular design: Adopting a modular structure design, it is small in size and can be easily installed in the standard rack of the VM600 system, saving installation space. In the control cabinet with limited space, it can be flexibly matched with other modules to improve the rationality of the system layout.

Convenient installation and replacement: It supports rack mounting, and the installation process is simple and fast. The module can be fixed and wired without complex tools. When the module needs maintenance or replacement, it can be quickly disassembled, reducing system downtime. For example, in the production line monitoring system, the quick replacement of modules can minimize the impact of equipment maintenance on production.

Status indication and diagnosis: It is equipped with abundant status indicators, which can intuitively display the power status, communication status, operation status and other information of the module. At the same time, it has a built-in self-diagnosis function. When the module fails, it can send fault information through indicators or communication interfaces, facilitating maintenance personnel to quickly locate the cause of the fault and improve maintenance efficiency.

III. Application Fields

(1) Energy and Power Industry

Generator set monitoring: In the monitoring systems of thermal, hydro, and wind generator sets, the CPUM module, as the core processing unit, conducts real-time analysis of parameters such as vibration, speed, temperature, and pressure of the units. It can timely detect problems such as rotor imbalance, bearing failure, and stator overheating, ensure the safe and stable operation of generator sets, improve power generation efficiency, and reduce downtime losses caused by faults.

Transmission and distribution equipment management: It is used for the monitoring and management of substation equipment, integrates the monitoring data of transformers, high-voltage switches and other equipment, and analyzes the operating status of the equipment. Through the analysis of transformer oil temperature and vibration, it can judge whether there is a fault inside the transformer; monitor the number of operations and contact temperature of high-voltage switches to ensure the reliable operation of switchgear.

(2) Petrochemical Industry

Rotating equipment monitoring: In the monitoring systems of rotating equipment such as compressors, pumps, and fans in petrochemical production, the CPUM module can conduct in-depth analysis of equipment data such as vibration, speed, and oil pressure to identify early faults of the equipment. For example, in centrifugal compressor monitoring, through the analysis of vibration spectrum, faults such as impeller wear and shafting misalignment can be found in advance to avoid serious damage to the equipment during high-speed operation.

Reaction equipment control: It is used for the monitoring and control of chemical reaction kettles and other equipment, integrates the monitoring data of temperature, pressure, liquid level, etc. in the reaction kettle, and optimizes the control of the reaction process through built-in algorithms. When abnormal parameters are detected, it timely issues an alarm and links the control module to make adjustments, ensuring the safety and stability of the reaction process and improving product quality.

(3) Manufacturing Industry

Machine tool equipment monitoring: In the monitoring systems of machine tools such as CNC machine tools and machining centers, the CPUM module conducts real-time analysis of parameters such as vibration of the machine tool spindle, displacement of the feed axis, and cutting force. It can timely find problems such as tool wear and spindle bearing failure, remind operators to replace tools or perform maintenance, ensure machining accuracy, and reduce the scrap rate.

Automated production line management: As the core of the automated production line monitoring system, the CPUM module integrates the monitoring data of various equipment in the production line (such as robots, conveyors, assembly machines, etc.) to conduct comprehensive monitoring of the operating status of the production line. When a certain equipment fails, it can quickly locate the fault location and issue a command to suspend relevant processes to avoid fault spread and improve the operating efficiency of the production line.

VIBRO-METER 200-595-100-014 200-595-072-122 VM600 CPUM CPU Board

VIBRO-METER 600-003 620-001-001-116 VM600 XMV16 Regulator Module

VIBRO-METER 620-002-000-113 620-003-111-112 VM600 XIO16T Communication Interface Card

Vibro-meter MPC4 200-510-078-115 Machinery Protection Card

Vibro-meter VM600 MPC4 200-510-064-034 200-610-100-034 Machinery Protection Card

GE IS420YDIAS1B Discrete Output I/O Pack

GE IS420YAICS1B Analog I/O Pack

GE IS420YDOAS1B Discrete Output I/O Pack

GE IS410STCIS2A Compact Contact Input Terminal Board

GE IS410STAIS2A Analog I/O Module

GE IS410SRLYS2A Simplex Terminal Board

GE IS400STCIS2AFF Terminal Board

GE IS400STAIS2AED Simplex Terminal Board

GE IS400SRLYS2ABB Simplex Terminal Board

GE IS200JPDMG1ACC Power Distribution Card

GE IS420UCSCH1A-F-V0.1-A Controller

GE UCSC H1 IS420UCSCH1A-B Controller

GE PRG-MODEM Regulator module

GE WES5162 Frame rack

Allen-Bradley 1756-2WS Weigh Scale Module

RELIANCE ELECTRIC S-D4012 PLC controller

LAM 810-800082-043 VME BREAKOUT BOARD

Allen-Bradley 1756-A7 Seven (7) slot Chassis

Allen-Bradley 1756-A13 Seven (13) slot Chassis

Allen-Bradley 1756-CN2R ControlNet Communication Module

Allen-Bradley 1756-CN2RXT Controlnet Redundant Interface Module

Allen-Bradley 1756-CNB ControlNet Interface Module

Allen-Bradley 1756-DHRIO ControlLogix DH Plus/RIO Comms Module

Allen-Bradley 1756-DNB DeviceNet Scanner Module

Allen-Bradley 1756-EN2T Communication Module

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.