Home > Products > Component and physical-chemical testing > Used TRIOPTICS OptiCentric Smart 2R High - Precision Optical Centering Machine

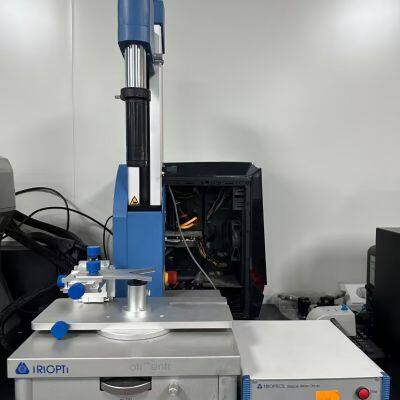

Used TRIOPTICS OptiCentric Smart 2R High - Precision Optical Centering Machine

- 0 Piece / Pieces per Month

- ShenZhen

- T/T Other

- 30 days

You May Like

Product Details

| Application | Other, Optical lens manufacturing | After-sales Service | Negotiate | |

| Transport Package | Wooden Box Package | Specification | / | |

| Trademark | TRIOPTICS | Origin | Germany |

Product Description

Brand: TRIOPTICS (A well - known German manufacturer of optical measurement equipment, specializing in the research and development of optical inspection technology. Its products are used in high - end optical manufacturing and scientific research fields worldwide)

Model: OptiCentric Smart 2R

Place of Origin: Wedel, Germany

Equipment Attribute: Used high - precision optical centering machine. It has undergone professional inspection and maintenance, with stable performance, suitable for optical component production and quality inspection scenarios

2. Core Functions and ApplicationsThe TRIOPTICS OptiCentric Smart 2R is a high - precision device designed specifically for eccentricity inspection of optical components, and it mainly addresses the following needs:

1. Eccentricity and Tilt Measurement: Accurately quantify the deviation (eccentricity) between the geometric center and the optical center of optical components such as lenses, prisms, and optical fibers, as well as the tilt angle of the components. This is crucial for ensuring the imaging quality of optical systems (such as camera lenses, microscope objectives) and the transmission efficiency of optical fibers. For example, in the production of high - end camera lenses, it can detect the eccentricity of each lens group to avoid problems such as image blur and distortion.

2. High - Precision Quality Control: It is used for incoming inspection of optical components in optical manufacturing enterprises and final product inspection in R & D institutions. It can quickly screen out unqualified products, reducing the risk of subsequent assembly failures and improving production efficiency. For optical component suppliers, it can also be used to verify product quality and provide reliable inspection reports.

3. Wide Compatibility: It is compatible with a variety of optical component types and sizes, including spherical lenses, aspherical lenses, prisms of different shapes, etc. Whether it is small - diameter precision optical components in the aerospace field or large - size optical lenses in the astronomical telescope field, it can provide accurate measurement.

3. Technical AdvantagesHigh - Precision Measurement: Adopting advanced optical measurement technology, the measurement accuracy can reach the micron level, which can meet the strict quality requirements of high - end optical products. The precision optical path design and high - sensitivity sensor ensure that even small eccentricity and tilt can be accurately captured.

Automated Operation: Equipped with an intelligent control system, it can realize automatic alignment, measurement, and data analysis of optical components. The operation process is simple and efficient, reducing the influence of human factors on measurement results. The automated workflow also allows for rapid batch inspection of optical components, improving inspection efficiency in mass production.

Stable and Reliable Performance: As a product of the German brand TRIOPTICS, it has excellent mechanical structure and optical performance. After professional maintenance of the used equipment, its core components (such as optical lenses, measurement sensors) are in good condition, ensuring long - term stable operation. The robust design also makes it adaptable to different working environments in the factory, such as temperature and humidity changes within a certain range.

4. Applicable Industries and ScenariosOptical Lens Manufacturing: Used for eccentricity inspection in the production process of camera lenses, microscope lenses, and telescope lenses to ensure the imaging quality of the lenses. It can be integrated into the lens assembly line for online inspection or used in the laboratory for sampling inspection of finished lenses.

Optical Fiber Communication: Detect the eccentricity of optical fiber connectors and optical fiber end faces to ensure the efficiency and stability of optical signal transmission. In the production of optical fiber communication devices, it can effectively control the quality of optical fiber components and reduce signal loss.

Aerospace and Military: For the inspection of high - precision optical components in aerospace optical systems (such as satellite cameras, airborne optical sensors) and military optical equipment, ensuring the reliability and accuracy of optical devices in extreme environments.

Scientific Research Institutions: As an important tool for optical research, it is used to study the optical properties of new materials and the design and optimization of optical components. It can provide accurate measurement data for scientific research projects, helping researchers to deeply understand the characteristics of optical components.

5. Equipment Status and After - salesEquipment Status: The used OptiCentric Smart 2R has been comprehensively inspected and maintained. The optical system has been calibrated, and the mechanical components have been lubricated and adjusted. The equipment is in good working condition and can be put into use immediately. Relevant inspection reports and maintenance records will be provided to ensure transparency of the equipment status.

After - sales Service: Provide a certain period of technical support, including remote debugging guidance, operation training (if required), and answer questions about equipment use and maintenance. For major failures, we can also provide on - site maintenance services (additional costs may apply depending on the situation). We are committed to ensuring that customers can use the equipment smoothly and solve problems in a timely manner.

Contact Us

- Shenzhen Vidocq Technology Co., Ltd.

- Contact nameZhou Jingrong Chat Now

- Addressbaoanqu songgangjiedao xitoushequshajianglu162hao1dong1hao810, Shenzhen, Guangdong

Product Categories

New Products

-

Used FARO Quantum S 4m Portable Coordinate Measuring Machine

-

ZEISS ACCURA II 9/16/8 Bridge - Type Coordinate Measuring Machine

-

Used Mettler Toledo XP56 Microbalance

-

Second-hand Mettler Toledo XP205 Lab Balance with SmartGrid Technology

-

Used KOSAKA Roughness Tester - High Precision Surface Measurement Instrument

-

Used KONICA MINOLTA Spectrophotometer CM - 2600d

-

Pre-owned KOSAKA ET4000L Step Profiler - High-precision Micro-shape Measurement Instrument

-

Pre-owned Laser Level LP31 - High-precision Measurement Tool for Construction & Decoration

-

Pre-owned Mitutoyo Surface Roughness Tester SJ-410 - Precision Measurement for Manufacturing Quality Assurance

-

Pre-owned Leica Tracker AT901-B - High-precision Portable 3D Measurement Solution for Industrial Applications

-

Used Bruker Dektak XT-A Profilometer - High - Precision Surface Metrology Instrument

-

Used Keyence VR6200 3D Profilometer Controller - High Precision, Cost - Effective & Ready to Use

-

OGP Optical Two - Dimensional Image Measuring Instrument - High - Precision Non - Contact Metrology Solution

-

Pre-owned Taylor Hobson Talyrond 265 Roundness Tester – Precision Metrology Instrument for Circular Geometry Measurement

-

Used Taylor HOBSON S5K Surface Profilometer

-

Used JEOL JSM-7400F Field Emission Scanning Electron Microscope (FE-SEM)

-

Used X - Rite Color Difference Meter

-

Used Rigaku X - Ray Diffractometer (XRD)

-

Used TESA Micro - Hite M 600 High - Precision Height Gauge

-

Used SPECTRO SPECTROMAXx LMF05 Direct - Reading Spectrometer

-

Used Olympus DSX510 Digital Microscope

-

Used KEYENCE VHX950F Ultra - Deep Field Microscope

-

Zeiss Gemini Sigma 300 VP SEM (Variable Pressure Scanning Electron Microscope)?

-

Used Hitachi TM - 3030 Scanning Electron Microscope

Recommended Products

- Used TA Rheometer AR1500EX - High - Precision Rotational Rheometer for Material

- Used Keyence IM6120 Flash Measuring Instrument

- Used Fischer X - ray Film Thickness Gauge

- RONDCOM 54DX Roundness Measuring Machine

- Used Keyence VR5200 3D Profilometer

- Used Bruker Contour GT White Light Interferometer

- PET bottle cap liquid level spray code detection equipment On-line vision detector

- Inspection equipment for liquid level spraying code of transparent bottle products On-line visual inspection equipment

- On-line code-spraying detection equipment date code-spraying detection equipment for food, drink and beer high-speed products

- Liquid level detector The liquid level detection equipment of cans can be adapted to high-speed production line.

- Used Taylor HOBSON S5K Surface Profilometer

- Pre-owned Taylor Hobson Talyrond 265 Roundness Tester – Precision Metrology Instrument for Circular Geometry Measurement

Find Similar Products By Category

- Instruments & Meters > Automated Inspection Equipment

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Zhou Jingrong

Hi there! Welcome to my shop. Let me know if you have any questions.

Zhou Jingrong

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile