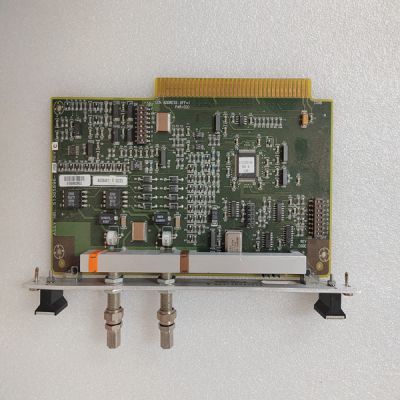

HONEYWELL 51305896-200 NIM MODEM

- 162 Piece / Pieces per Month

- T/T

- 1 days

You May Like

Product Details

| Brand Name | HONEYWELL | Place of Origin | China | |

| Model Number | 51305896-200 NIM MODEM |

Product Description

Brand: HONEYWELL

Type:51305896-200 NIM MODEM

Origin: the United States

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts of our products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

MIN CASCADE SETPOINT (UNITS) dflt= 0.0 (-20000, 20000) Set the minimum cascade setpoint followed by ENTER. This value is the minimum setpoint value that the cascade setpoint can be decreased/lowered to (lower limit of cascade setpoint). MAX CASCADE SETPOINT (UNITS) dflt= 100 (-20000, 20000) Set the maximum cascade setpoint followed by ENTER. This value is the maximum setpoint value that the cascade setpoint can be increased/raised to (upper limit of cascade setpoint). (Must be greater than the ‘Min Cascade Setpt’ Setting) CASC SETPT RATE (UNITS/SEC) dflt= 5.0 (0.01, 1000) Set the cascade setpoint rate followed by ENTER. This value is the rate (in units per second) at which cascade setpoint moves when adjusted. USE SETPOINT TRACKING? dflt= NO (Yes/No) Select YES or NO followed by ENTER. If YES, the cascade setpoint tracks the cascade input to provide bumpless transfer to cascade control when it is enabled. If NO, the cascade setpoint remains at the last position except on power-up or exiting the program mode. SETPT INITIAL VALUE (UNITS) dflt= 100 (-20000, 20000) Set the setpoint initialization value followed by ENTER. When not using the Setpoint Tracking function, this is the value that the cascade setpoint initializes to upon power-up or exiting the program mode. (Must be less than or equal to the ‘Max Cascade Setpt’ Setting) SPEED SETPOINT LOWER LIMIT (RPM) dflt= 3605 (0.0, 20000) Set the minimum speed setpoint that the cascade controller can lower the speed setpoint to followed by ENTER. To protect the unit, this value should be at or above rated speed if the unit is a generator. (Must be greater than or equal to the ‘Minimum Governor Speed Setpt’ Setting) SPEED SETPOINT UPPER LIMIT (RPM) dflt= 3780 (0.0, 20000) Set the maximum speed setpoint that cascade controller can raise the speed setpoint to followed by the ENTER key. (Must be less than or equal to the ‘Maximum Governor Speed Setpt’ Setting) MAX SPEED SETPOINT RATE (RPM/SEC) dflt= 20 (0.1, 100) Set the maximum rate at which the cascade control can vary the speed setpoint followed by the ENTER key. CASCADE DROOP (%) dflt= 0.0 (0.0, 100) Enter the droop percentage followed by the ENTER key. If needed, typically set between 4-6% and not more than 10%. CASCADE PID PROPORTIONAL GAIN (%) dflt= 5.0 (0.0, 100) Enter the cascade PID proportional gain value followed by ENTER. This value is used to set cascade control response. This value can be changed in the Run Mode while the turbine is operating. If unknown, a recommended starting value is 1%. CASCADE PID INTEGRAL GAIN dflt= 0.3 (0.001, 50.0) Enter the cascade PID integral gain value, in repeats-per-second (rps) followed by ENTER. This value is used to set cascade control response. This value can be changed in the Run Mode while the turbine is operating. If unknown, a recommended starting value is 0.3 rps. CASCADE PID DERIVATIVE RATIO (%) dflt= 100 (0.0101, 100) Enter the cascade PID derivative ratio followed by ENTER. This value is used to set cascade control response. This value can be changed in the Service Mode while the turbine is operating. If unknown, a recommended starting value is 100%. USE REMOTE CASCADE SETTING? dflt= NO (Yes/No) Set to YES to allow the Cascade setpoint to be adjusted from an analog input. (Must program a ‘remote cascade setpoint’ analog input)

Contact Us

- Temporal Ming sheng automation equipment co., LTD

Product Categories

New Products

-

LAM 810-800082-043

-

S21260-SRS

-

IS200SRTDH2ACB

-

IS220PAICH2A 336A4940CSP11

-

IS220PDIAH1A 336A4940CSP1

-

IS220PDOAH1A 3364940CSP2

-

IS220PRTDH1BC 336A5026ADP13

-

IS230SNRTH2A

-

SR469-P5-HI-A20

-

EATON XVS-430-10MPI-1-10

-

LC-608

-

DSAI130D 3BSE003127R1

Popular Searches

- spare parts

- remote control

- Pcb Circuit

- home automation

- smart home system

- pcb assembly

- circuit board

- energy saving

- Lighting System

- control panel

- Control Box

- Pcb Design

- pcb module

- lab equipment

- remote control switch

- Wire Harness

- Silicone Bracelet

- industrial dehumidifier

- Rubber Keyboard

- silicone keypad

- computer mainboard

- mainboard

- access control equipment

- Solenoid Valve

- Power Distribution Equipment

- Radio Remote Control

- Crane Remote Control

- Industrial Wireless Remote Control

- Industrial Radio Remote Control

- Multilayer Circuit Board

Recommended Products

- Bently Nevada 31000-27-05-00-035-03-02

- Bently Nevada 31000-30-05-15-31-03-02

- Bently Nevada 31000-30-05-40-14-03-02

- Bently Nevada 31000-28-05-35-032-03-02

- Bently Nevada 330707-00-25-10-02-00

- Bently Nevada 330102-00-36-05-02-05

- Bently Nevada 330130-030-00-05

- Bently Nevada 330101-00-08-20-02-05

- Bently Nevada 330730-040-13-CN

- Bently Nevada 330730-040-13-00

- Bently Nevada 330730-040-12-CN

- Bently Nevada 330730-040-12-00

Find Similar Products By Category

- Electrical & Electronics > Power Transmission & Transformer > Transformer