Automated rubber stopper inspection machine is a custom built equipment used for rubber stopper quality control. Normally, we choose offline vision inspection mechanism for this kind of rubber products. A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware. Stoppers made of cork are also available for this purpose.

Let’s introduce how we make a customized built machine for our clients.

First of all, send us your inspection requirements as many as possible, telling us what’s the size of the rubber stoppers, what’s the surface defects you want the machine to detect. Our engineer will have a first evaluation about your requirements and then will decide whether we can continue the project.

Secondly, when the project is feasible to do. We will ask customer to prepare samples both OK and NG 10 pieces for each type of features for each models. Customer will help to label the NG samples telling which kind of defects they are. After receiving the samples, our engineer will arrange a lighting test.

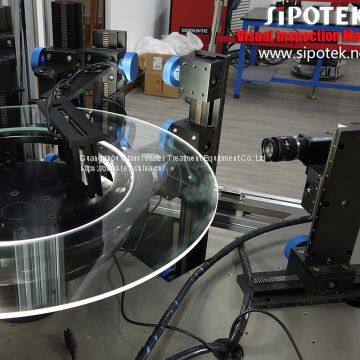

Applications Visual Inspection Machines From China

Applications Visual Inspection Machines From China