Home > Products > Fiberglass grille > FRP Fiberglass Reinforced Plastics REDCO FRP GRATING

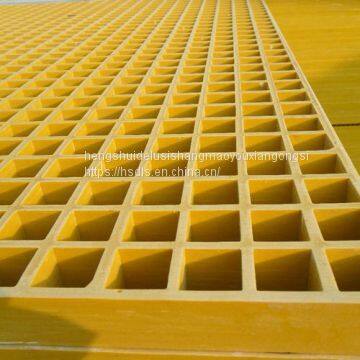

FRP Fiberglass Reinforced Plastics REDCO FRP GRATING

- 66666 Inch / Inches per Month

- tianjin

- T/T L/C D/P D/A Credit Card PayPal Other Cash Escrow

You May Like

-

Fiberglass Reinforced Plastic Molded Grating | Emco Industrial Plastics

-

Fiberglass Reinforced Plastic Molded Grating | Emco Industrial Plastics

-

china Fiberglass Reinforced Plastic Molded Grating | Emco Industrial Plastics

-

china Fiberglass grille Frp material floor fiberglass grilling grating

-

Fire Resistant Fiberglass Reinforced Plastic Grille For Walkway

-

Pultrusion of fiberglass reinforced plastic grille/grating

Product Details

| Brand Name | delusi | Place of Origin | China | |

| Model Number | 1.22*3.66 |

Product Description

The raw materials

(1) synthetic resin: composite molding products used in the molding material requirements of synthetic resin with: (1) to strengthen the material has a good infiltration performance, in order to form a good bond on the interface of synthetic resin and reinforcing materials;(2) has the appropriate viscosity and good fluidity, under the pressure conditions and the reinforcement material can be uniformly filled with the entire cavity;(3) in the pressure conditions have the appropriate curing speed, and the curing process does not produce by-products or by-products, volume shrinkage is small;(4) to meet the mold products specific performance requirements.According to the above selection requirements, commonly used synthetic resins are: unsaturated polyester resin, epoxy resin, phenolic resin, vinyl resin, furan resin, silicone resin, polybutadiene resin, allyl ester, melamine resin, polyimide resin, etc..In order to make the molded products achieve specific performance indicators, in the selection of resin varieties and brands, should also choose the corresponding auxiliary materials, fillers and pigments.

(2) reinforced material, moulding material that is commonly used in reinforced material mainly operate on the glass fiber silk, roving, roving, continuous glass fiber bundles, glass fiber cloth, glass fiber mat and so on, also have a small amount of special products choose asbestos blanket fabric (cloth), asbestos and asbestos paper and high silica fiber, carbon fiber, organic fiber (such as aramid fiber, nylon fiber, etc.) and natural fibers, such as linen, cotton cloth, scouring cloth, scouring cloth, etc.) and other varieties.Sometimes two or more fiber mixtures are used as reinforcing materials.

(3) auxiliary materials

Generally, it includes curing agent (initiator), accelerator, diluent, surface treatment agent, low-shrinkage additive, mold release agent, colorant (pigment), filler and other auxiliary materials.

2. Preparation of molding materials

Taking the molding material made of glass fiber (or glass cloth) impregnated resin as an example, the production process can be divided into two methods: premix and prepreg.

(1) premixing method: first cut glass fiber into 30 ~ 50mm chopped fiber, after puffiness, kneaded with resin glue solution in kneading machine until resin completely infiltrates glass fiber, and then dried (dried) to appropriate viscosity.It is characterized by loose and directionless fiber and large production capacity. The molding material produced by this method has large specific volume and good fluidity, but the fiber strength loss is large in the preparation process.

(2) prepreg method: fiber prepreg method is to dip the whole bundle of continuous glass fiber (or cloth), dry, cut short.It is characterized by the fiber bundles, relatively compact, the preparation of molding materials in the process of fiber strength loss is small, but molding materials fluidity and compatibility between the bundles is slightly poor.

Manufacturing technology of SMC, BMC, HMC, XMC, TMC and ZMC

Sheet Molding Compound (SMC) is a kind of Sheet Molding Compound, which is made by impregnating fiber or chopped fiber felt with resin and covering polyethylene film on both sides.It is one of the most widely used molding materials in the world.

SMC is a mixture of unsaturated polyester resin, thickener, initiator, crosslinking agent, low shrinkage additive, filler, internal mold release agent and colorant into a resin paste impregnated short-cut fiber roving or glass fiber felt, and on both sides with polyethylene or polypropylene film covered by the formation of sheet molding material.SMC, as a rapidly developing new molding material, has many characteristics:

(1) good reproducibility, not affected by the operator and external conditions;

Convenient operation and handling;

(3) the operation environment is clean and sanitary, improving working conditions;

(4) good liquidity, can be shaped shaped products;

(5) molding process for temperature and pressure requirements are not high, wide range of variable, can greatly reduce equipment and mold costs;

6 fiber length 40 ~ 50mm, good quality uniformity, suitable for pressing section change is not large thin-walled products;

After adopting low shrinkage additive, the surface quality is more ideal.

Today high production efficiency, molding cycle is short, easy to achieve automatic mechanization operation, production costs are relatively low.

As a new material, SMC has developed a series of new products according to different applications and requirements, such as BMC, TMC, HNC, XMC, etc.

Bulk Molding Compound (BMC), whose composition is very similar to the SMC, is an improved premixed Molding Compound, and can be used for Molding and extrusion.The difference between the two lies only in the shape of the material and the manufacturing process.The strength of BMC products is lower than that of SMC products. BMC products are more suitable for pressing small products, while SMC products are more suitable for large thin-walled products.

Thick Molding Compound (TMC) is similar to the SMC, with a thickness of 50mm.Due to the large thickness of TMC, glass fiber can be distributed randomly, which improves the permeability of resin to glass fiber.In addition, the material can be molded by injection and transfer molding.

High strength Molding Compound (HMC) and high strength sheet Molding Compound XMC are mainly used for manufacturing auto parts.HMC without or less filler, using chopped glass fiber, fiber content of about 65%, glass fiber directional distribution, with excellent fluidity and molding surface, the strength of its products is about 3 times of SMC products.XMC USES directional continuous fiber, with fiber content up to 70% ~ 80%, without filler.

(4) ZMC ZMC is a molding technology, ZMC three letters does not have the actual meaning, but contains molding plastics, injection molding machinery and mold three meanings.ZMC products not only maintain high strength index, but also have excellent appearance and high production efficiency.

Contact Us

- hengshuidelusishangmaoyouxiangongsi

- Contact namezhanghaiwei Chat Now

- Phone86-0318-2661773

Product Categories

| Fiberglass grille | Glass reinforced plastic softens water tanks | Glass fiber softens water tanks | Glass Fiber Reinforced Plastic Sand Pipe Dewatering Pipe |

| Glass fiber sand pipe |

New Products

-

FRP Grating panel & Fiberglass Grilling for Staircase & Fiberglass Gratings

-

Grille Used Fiberglass Deck

-

fiberglass solid grille/tree protection frp grating

-

fiberglass solid grille / water resistance steel grating / tree protection frp grating

-

Fiberglass Grating Walkway, FRP Grill

-

Molded glass fiber grating

-

Molded glass fiber grating

-

Molded vs. Pultruded Fiberglass Grating

-

Fiberglass products Fiberglass tube Molded glass fiber grating

-

Fiberglass products Fiberglass tube Molded glass fiber grating

-

Glass reinforced plastic softens water tanks

-

Fiberglass Reinforced Plastic Molded Grating | Emco Industrial Plastics

-

Glass fiber softens water tanks manufactured in China

-

Glass reinforced plastic softens water tanks price Using this Dictionary

-

Glass fiber sand pipe Glass Fiber Reinforced Plastic Sand Pipe Dewatering Pipe

-

made in china Glass fiber sand pipe Glass Fiber Reinforced Plastic Sand Pipe Dewatering Pipe

-

Glass fiber sand pipe Glass Fiber Reinforced Plastic Sand Pipe Dewatering Pipe assembly method

-

drain-pipe Glass Fiber Reinforced Plastic Sand Pipe Dewatering Pipe assembly method

Popular Searches

- building material

- Fiberglass Fabric

- glass fiber

- wire mesh

- fishing boat

- rib boat

- Fiberglass Cloth

- frp rod

- fiberglass screen

- fiberglass netting

- fiberglass mat

- fiberglass mesh

- fiberglass tape

- fiberglass tissue

- fiberglass net

- fiberglass rod

- grp

- Frp Product

- Fiberglass Grating

- Fiberglass Chopped Strand Mat

- Glass Fiber Product

- Mesh Product

- Fiberglass Cast Tape

Recommended Products

- High torque waste metal shredder waste metal breaker crusher

- Professional hard drive shredder-mini small shredder

- Wholesale Hotsale Pure Water Treatment Custom Size Coal Based Coconut Shell Granular Activated Carbon

- Wholesale Hotsale Pure Water Treatment Custom Size Coal Based Coconut Shell Granular Activated Carbon

- Hot Sale Manufacturer Wood Based Black Activated Carbon Coal Based Coconut Shell activated carbon In Water Treatment For Water

- Firemax Active Charcoal Powder Coal Based Adsorbent Absorption Treatment Particles of Coal-based Activated Carbon

- Gold Mine Activated Carbon Coconut Shell Based Activated Carbon for Gold Mining Industry Recovery Absorption Extraction Leaching

- Cost Effective Coconut Shell Activated Carbon for Gold Extraction Great Value for Your Investment

- Powdered Activated Carbon for Rapid Water Purification and Sewage Treatment with High Efficiency in Adsorbing Heavy Metals

- Cubic Activated Carbon Aquarium Filter Water Purification Honeycomb Activated Carbon

- Coconut Shell Activated Carbon Is Used to Remove Impurities From Water.

- Air Filters Activated Carbon 1 Ton Activated Carbon Price Pellets Powder Granular Activated Charcoal for Water Treatment

Find Similar Products By Category

- Industrial Equipment & Components > Environment Protection Device > Waste Treatment Equipment

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhanghaiwei

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

zhanghaiwei

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile