Home > Products > BENTLY > BENTLY Nevada 140734-05 Dynamic Pressure Monitoring Module – Continuous Combustion and Pulsation Insight for Critical Rotating Assets

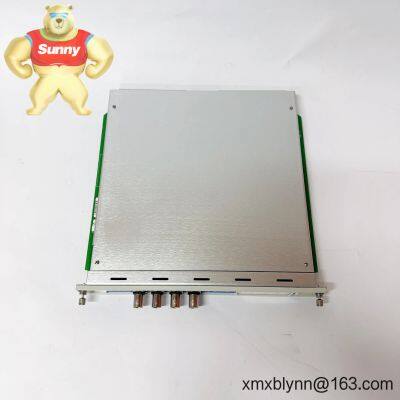

BENTLY Nevada 140734-05 Dynamic Pressure Monitoring Module – Continuous Combustion and Pulsation Insight for Critical Rotating Assets

≥1 Blades

- T/T

You May Like

-

Bently Nevada 176449-08 Piston Rod Position Monitor – Reliable Rod Motion Tracking for Reciprocating Compressors

-

Bently Nevada 140734-01 – Four?Channel Proximity Probe Monitor for 3500 Series Machinery Protection

-

Bently Nevada 184826-01 VGA Display Module – Real-time Rack Visualization for 3500 Systems

-

Bently Nevada 190782-01 Communication Gateway Module – Reliable Modbus/Ethernet Bridge for 3500 Monitoring Systems

-

BENTLY 288062-02 Two?Channel Tachometer Module – Precise Speed and Zero?Speed Monitoring for Bently Nevada 3500 Racks

-

Bently Nevada 323174-01 Emergency Shutdown Device – Hardwired Trip Protection for Critical Machinery

Product Details

| I/O Number | Bently Nevada 140734-05 | Place of Origin | America | |

| Communication Interface | Modubus | Product name | Variable frequency driver | |

| Model Number | Bently Nevada 140734-05 | Condition | NEW | |

| Warranty | One Year | Package | Original Packaging | |

| HS Code | 903289 |

Product Description

Warranty: 365 days

Delivery: 1 week if in stock; no more than one month at the latest

Payment: 50% advance payment; full payment prior to delivery

Express options: FedEx, UPS, DHL

Dynamic pressure channels: Optimized for piezoelectric pressure sensors to capture combustion and pulsation signatures with high bandwidth.

Real-time alarms (Alert/Danger): Configurable setpoints help you catch instability, surge, or flameout precursors early.

Buffered dynamic outputs: Front-panel BNC typically provides raw signal access for analyzers or portable recorders.

Keyphasor correlation (when available): Phase-referenced analysis for order tracking and synchronous investigations.

Rack integration: Works within the BENTLY Nevada rack ecosystem, leveraging backplane power, alarm relays, and system communications.

Noise-resistant measurements: Designed for harsh, high-EMI environments found around turbines and compressors.

| Brand / Model | BENTLY Nevada 140734-05 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus – Other) |

| Power Requirements | Powered via rack backplane; no separate external supply required |

| Dimensions & Weight | Single-slot plug-in module for BENTLY Nevada rack; typical 3U height, ~280 mm depth, ~0.4 kg |

| Operating Temperature | 0 to +65°C (typical for BENTLY rack modules) |

| Signal Input Types | Piezoelectric dynamic pressure transducers (IEPE/ICP or charge-type via conditioner); optional Keyphasor reference |

| Signal Outputs | Buffered dynamic output (front BNC); alarm status to rack relays; values available to system comms |

| Communication Interfaces | Via rack communications module (e.g., Ethernet through system monitor, where present) |

| Installation Method | Front-insert, rear I/O terminal base; single-slot rack mounting with field wiring at the rear |

Gas turbine combustion dynamics monitoring (DLN/lean-premix stability tracking).

Reciprocating compressor pulsation detection and anti-surge diagnostics.

Boiler and furnace acoustic monitoring to spot instability or flame anomalies.

Hydroacoustic/pipe resonance surveys in high-pressure process lines.

R&D and test stands needing phase-referenced pressure spectra and trends.

A maintenance engineer at a combined-cycle plant shared that adding dynamic pressure channels reduced nuisance turbine trips by letting them see and correct combustion rumble during load transitions.

Reliability: Industrial-grade design that typically holds calibration and signal integrity even near hot sections.

Compatibility: Seamless use with BENTLY racks, Keyphasor references, and existing historian/controls via rack comms.

Cost-conscious: Early detection of combustion instabilities and pulsations often prevents expensive unplanned outages.

Data confidence: Buffered outputs for portable analyzers; easy correlation with vibration and process tags.

Lifecycle support: Spares, configurable alarms, and firmware upgradability help extend system life in many cases.

Cabinet & environment: Install in a clean, ventilated 19-inch cabinet; maintain ambient 0–65°C, humidity below condensation.

Wiring: Use shielded, low-noise cables for dynamic pressure sensors; ground shields at the rack end; keep sensor cables away from power lines.

Sensors: Pair with suitable IEPE or charge-type dynamic pressure transducers; verify mount torque and orientation per OEM sensor guidance.

Safety: De-energize the rack slot before insertion or removal; follow site LOTO procedures.

Routine checks: Quarterly inspection of connector tightness, channel bias/health, and sensor drift; clean dust from front panel openings.

Calibration & firmware: Annual calibration against a reference source is recommended; keep firmware aligned with the rack system monitor for stability.

CE conformity; typically UL/cUL recognized for system use

RoHS compliant design

Manufactured under ISO 9001 quality systems

Standard warranty: 365 days

From my experience, pairing the 140734-05 with a stable Keyphasor and well-sited dynamic pressure sensors gives the clearest picture of combustion behavior, especially during startup and low-load operation. If you’re consolidating spares, this module seems to be a practical pick for fleets running modern DLN turbines or high-speed reciprocating compressors.

Company Profile

Xiamen Xiongba E-commerce Co., Ltd. is a control system component company, located in Siming District, Xiamen, a beautiful coastal city. Xiamen Xiongba E-commerce Co., Ltd. is one of the largest control system components in China, focusing on industrial automation PLC and DCS modules. Our company has 20 years of experience in the field of automatic control. We specialize in supplying world-renowned brands: Allen Bradley, ABB, General Electric, Triconex, Honeywell, Bentley Nevada, Schneider, Hima, and even some...

Contact Us

- Xiamen Xiongba E-commerce Co., LTD

- Contact nameLynn Chat Now

- Phone86-86-18059884797

- AddressRoom 2009, Chuangxiang Center, No. 1733, Luling Road, Siming District, Xiamen xmxblynn@163.com, Xiamen, Fujian

Product Categories

New Products

-

Bently Nevada 330101-00-25-20-12-05 Proximity Transducer – Field-mounted Proximitor for Reliable Shaft Vibration and Position Measurement

-

Bently Nevada 330103-00-12-10-02-CN Proximity Probe for 3300 XL Systems – Reliable Shaft Vibration and Position Measurement

-

Bently Nevada 330103-05-30-10-02-00 – Extension Cable for 3300 XL Proximity Transducer Systems

-

Bently Nevada 330104-00-05-05-01-05 Proximity Transducer – Non?contact Shaft Vibration and Position Sensing for Critical Machinery

-

Bently Nevada 330104-05-11-10-02-CN – 8 mm Proximity Probe for 3300 XL Transducer Systems

-

BENTLY 330180-91-00 Proximitor Preamplifier – Eddy-current Proximity Sensor Conditioning for Reliable Shaft Vibration and Position

-

Bently Nevada 330104-11-22-10-02-CN – 3300 XL 5 mm Proximity Probe for Vibration and Shaft Position Monitoring

-

Bently Nevada 330876-03-50-00-00 50 mm Proximity Probe – Long?reach Non-contact Sensing for Critical Rotating Machinery

-

Bently Nevada 3500/05-01-02-00-00-01 System Monitor – Core Control for the 3500 Condition Monitoring Rack

-

Bently Nevada 3500/05-01-02-00-00-00 System Rack (Framework Module) – Backplane & Housing for 3500 Machinery Protection

-

Bently Nevada 3500/20-01-01-00 Rack Interface Module — Framework Communications for the 3500 Protection System

-

Bently Nevada 3500/05-02-04-00-00-00 System Rack — Chassis for 3500 Machinery Protection Modules

-

Bently Nevada 3500/22M (P/N 288055-01) – Transient Data Interface for 3500 Machinery Protection Racks

-

BENTLY 3500/91M EGD Communication Gateway – Deterministic Ethernet Link From Your 3500 Rack to GE Control Networks

-

BENTLY 3500/42M 176449-02 — Multi-channel Proximitor/Seismic Monitor for Critical Machinery Protection

-

Bently Nevada 3500/92-01-01-00 Communication Gateway Module – Ethernet Bridge for 3500 Rack Data to DCS/SCADA

-

Bently Nevada 3500/70 Expansion Monitoring Module – Real-time Turbine Expansion Measurement and Machinery Protection

-

Bently Nevada 9200-06-01-10-00 Velocity Seismoprobe – Reliable Case Vibration Sensing for Rotating Machinery

-

Bently Nevada 125388-01 Half-Height Module – Compact I/O Interface for Machinery Condition Monitoring Racks

-

Bently Nevada 3500/95 System Display – Local Rack Display for 3500 Machinery Protection Data

-

Bently Nevada 129478-01 DC Power Input Module – Stable DC Feed for Machinery Protection Racks

-

Bently Nevada 132417-01 Vibration Monitoring Module – Machine Protection and Condition Monitoring for Critical Rotating Assets

-

Bently Nevada 135489-01 I/O Module – Rear I/O Termination for 3500 Machinery Protection Racks

-

Bently Nevada 135462-01 – 16?Channel Relay Module for 3500 Machinery Protection Racks

Popular Searches

- general purpose relay

- car relay

- ssr

- relay socket

- solid state relay

- pcb relay

- t90

- power relay

- electric relay

- pin relay

- mini relay

- timer relay

- time relay

- thermal relay

- thermal overload relay

- purpose relay

- digital timer control relay

- latching relay

- magnetic latching relay

- high power relay

- industrial relay

- controller relay

- contactor relay

- phase latching relay

- internet of thing

- electronic relay

- miniature relay

- ssr solid state relay

- ac solid state relay

- industrial solid state relay

Find Similar Products By Category

- Electrical & Electronics > Relay & Contactor > Relay

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lynn

Hi there! Welcome to my shop. Let me know if you have any questions.

Lynn

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile