Home > Products > Solar Tracking System > 2*26 Photovoltaic Array Tracking Solar Bracket

2*26 Photovoltaic Array Tracking Solar Bracket

5 - 19 Sets

20 - 49 Sets

≥50 Sets

- Tianjin

- T/T L/C PayPal D/P Western Union Other

- 35 days

You May Like

-

Complete System Equipment of Small Ground Solar Power Station

-

Olar Photovoltaic Energy Storage Charging Parking Shed

-

Steel Structure Photovoltaic Carport Processing Manufacturer

-

H-shaped Steel Home Photovoltaic Carport

-

Q335BH Steel Solar Parking Shed China Field Manufacturers Supply

-

Double Row Solar Parking Shed Manufacturer

Product Details

| Material | Metal | Type | Tracking Bracket | |

| Certification | ISO, CE | Warranty | one years | |

| Application | Commercial | Specification | Customized | |

| Trademark | Shuobiao | Origin | China |

Product Description

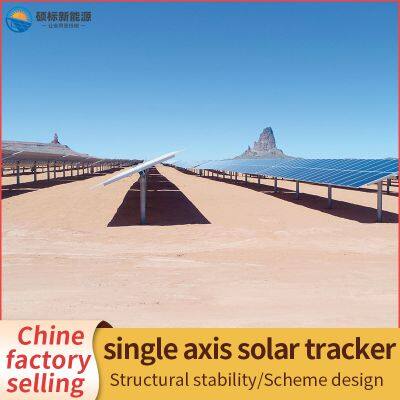

A 2×26 photovoltaic(PV)array tracking solar bracketrefers to a mounting system designed to support52 solar panels(2 rows of 26 panels each)withsolar tracking capability,allowing the panels to follow the sun’s movement for increased energy production. Below are key details about this system:

1. System Overview

-Array Layout:2 rows×26 panels(total 52 panels).

-Tracking Type:Likely asingle-axis tracker(horizontal or tilted)ordual-axis tracker(more precise but costly).

-Panel Capacity:Depends on panel size(e.g. ,500W panels→~26 kW total system).

-Structure Material:Typically aluminum(lightweight,corrosion-resistant)or galvanized steel(stronger for windy areas).

2. Key Components

A.Tracking Mechanism

-Drive System:Motorized actuators or slewing drives adjust panel angles.

-Control System:Uses sensors(sun position,GPS,or algorithms)to optimize tilt.

-Power Supply:May integrate PV-powered motors or grid connection.

B.Mounting Structure

-Torque Tubes/Frames:Rotating beams that hold panels in place.

-Foundation:Ground screws,ballasted blocks,or concrete piers(depends on soil/wind conditions).

-Bearings&Pivots:Enable smooth rotation(critical for durability).

C.Panel Attachment

-Clamps:Rail-less or rail-based systems secure panels to the tracker.

-Wiring Management:Cable trays protect wires from movement-induced wear.

3. Advantages of Tracking vs.Fixed-Tilt

-Energy Gain:Single-axis tracking boosts output by15–25%,dual-axis by30–40%(vs.fixed).

-Land Efficiency:Higher energy per square meter.

-Adaptability:Better performance in low-light or diffuse sunlight conditions.

4. Design Considerations

-Wind Load:Tracking systems must withstand dynamic forces(IEC 61427 standards).

-Backtracking:Prevents row-to-row shading during early/late sun positions.

-Slope&Terrain:May require grading or custom foundations.

-Maintenance:Moving parts need lubrication and occasional servicing.

5. Installation Steps

1. Site Prep:Level ground,install foundations.

2. Assemble Tracker Structure:Torque tubes,supports,drives.

3. Mount Panels:Attach with clamps,connect wiring.

4. Calibrate Tracking:Test sensor alignment and rotation limits.

Contact Us

- Hebei Shuobiao New Energy Technology Co., Ltd.

- Contact namelixianhong Chat Now

- AddressShenzhou City, Hengshui, Hebei

Product Categories

| Solar carport system | Solar Tracking System | Fixed solar support | Solar power system |

New Products

-

Square Tube Material Solar Parking Shed Height and Width Customization

-

Single Axis Solar Tracker

-

Dual Axis Solar Tracker

-

6 Meters Long Solar Support, Zinc-aluminum-magnesium U-shaped Steel

-

Solar Photovoltaic Carport Support Wholesale Hsuobiao

-

Fully Automatic Rotating Solar Support, China Manufacturer

Popular Searches

- rooftop

- mount bracket

- support bracket

- solar panel mount bracket

- mount accessory

- screw pile foundation

- rail system

- solar tracking system

- roof hook

- ground mount

- solar carport

- galvanized bracket

- adjustable bracket

- ground

- solar panel mounting frame

- aluminum bracket

- flat hook

- mount hook

- t5 bracket

- tracker system

- bipv module

- solar bracket

- panel channel

- aluminum rail

- solar tracker

- slewing tracking

- solar tracking

- rail mount

- ground solar bracket

- roof mount bracket

Recommended Products

- Customized BALLASTED ROOF MOUNTING SYSTEM Solar Bracket Framed or Frameless Landscape or Portrait

- METAL ROOF MOUNTING SYSTEM Solar Bracket Framed or Frameless 0°-60°Flushed or Tilted With Roof

- Olar Photovoltaic Energy Storage Charging Parking Shed

- Household Sun-tracking Solar Bracket

- NSPV Patent Design Solar Photovoltaic NEHP Edge Connector PV Panel NEHP01 Junction Box

- ShuoBiao Source Factory of Photovoltaic Carports

- Motor Control System for Flat Single-axis Tracking Bracket

- Small Photovoltaic Solar Charging Carport Have a Factory

- Solar Cell PV Round Soldering Ribbon Production Line For Making Round Ribbon

- Solar Cell PV Round Soldering Ribbon Production Line For Making Round Ribbon

- REOO Manufacturering Solar Cell Stringer Robot Laying Up Machine With Positioning Camera for Solar Panel Production Line

- REOO Manufacturering Solar Cell Stringer Robot Laying Up Machine With Positioning Camera for Solar Panel Production Line

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Solar & Renewable Energy > Solar Brackets

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

lixianhong

Hi there! Welcome to my shop. Let me know if you have any questions.

lixianhong

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile