Home > Products > Nickel Alloy > Cut to Length Alloy 36 Steel Plate UNS K93603 Invar 36 Corrosion Resisting

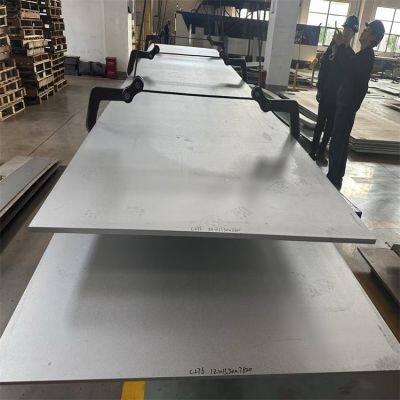

Cut to Length Alloy 36 Steel Plate UNS K93603 Invar 36 Corrosion Resisting

- Shanghai

- T/T L/C PayPal D/P Western Union Other

- 7 days

You May Like

-

Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy Components

-

Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy Forgings

-

Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy Parts

-

High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy Components

-

Inconel 600 Forgings - Steam Oxidation Resistance, Heat Exchangers | Industrial Superalloy Parts

-

Inconel X-750 Forgings - Spring Applications, 700°C Strength | High-Fatigue Superalloy Components

Product Details

| Type | Steel Plate | Certification | ISO | |

| Warranty | a year | Technique | Hot Rolled | |

| Application | Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate | Surface Treatment | Milling | |

| Standard | ASTM | Stock | Stock | |

| Special Use | Wear Resistant Steel | Transport Package | Wooden crate | |

| Specification | 0.1~60mm | Origin | China |

Product Description

Invar 36 Steel Plate - Product Details

Invar 36 steel plate is a nickel-iron alloy (containing 36% nickel), renowned for its extremely low coefficient of thermal expansion (CTE) and dimensional stability. It is widely used in precision fields with high temperature sensitivity requirements. Below are its core product details:

I. Material Properties1. Chemical Composition

? Nickel (Ni): 35.0-37.0%

? Iron (Fe): Balance

? Other elements: Carbon (≤0.05%), Manganese (≤0.60%), Silicon (≤0.30%), Phosphorus (≤0.02%), Sulfur (≤0.02%).Impurity content varies slightly across standards (e.g., ASTM F1684, EN 1.3912), but the core composition remains consistent.

2. Physical Properties

? Density: 8.1 g/cm3

? Melting Point: 1430-1450℃

? Coefficient of Thermal Expansion (CTE):

? 20-50℃: 0.6×10??/℃

? 20-200℃: 2.0×10??/℃

? 20-500℃: 10.0×10??/℃ (gradually increasing with temperature)

? Curie Point: Approximately 230℃. Below this temperature, the alloy is ferromagnetic, with the lowest expansion coefficient.

3. Mechanical Properties

? Tensile Strength: 400-690 MPa

? Yield Strength: 216-345 MPa

? Elongation: ≥20%

? Elastic Modulus: 140-148 GPaPerformance is more stable in the annealed state. Annealing at 850-900℃ is recommended to eliminate stress.

II. Product Specifications? Thickness: 0.3-1200 mm

? Width: Max. 2500 mm

? Length: Max. 12 m; customizable coils or plates available

? Surface Treatment: Offers 1D, 2B, BA, 3/4/6/7-grade surfaces (polished, sandblasted, etc.).

III. Production Standards? International Standards: ASTM F1684 (free-machining type), EN 1.3912 (Germany), UNS K93600 (USA).

? Chinese Standard: 4J36 (equivalent to Invar 36).

? Flaw Detection Standards: GB/T 5616-2006, GB/T 15024.

IV. Processing & Welding? Forming Process: Suitable for hot/cold rolling, with forming processes similar to austenitic stainless steel.

? Welding Recommendations: Use CF36 filler metal (GTAW/GMAW processes). Interpass temperature should be below 120℃ to avoid thermal stress.

? Heat Treatment: Full annealing (850-900℃) optimizes dimensional stability; customized stabilization processes are available for special applications.

V. Typical Applications4. Aerospace: Satellite structural components, cryogenic fuel storage tanks, precision instrument brackets.

5. Electronics Industry: Wafer carriers for semiconductor equipment, integrated circuit packaging frames.

6. Optical Instruments: Telescope tubes, laser component brackets (reducing temperature-induced optical path deviation).

7. Cryogenic Engineering: LNG transport pipelines, liquid helium containers (maintaining low expansion at -200℃).

8. Precision Machinery: Clock balance wheels, measuring tools, thermostat components.

VI. Notes? Corrosion Resistance: Performs well in dry environments but may rust in humid conditions. Surface coating or passivation is recommended.

? Temperature Limit: Long-term service temperature is advised below 200℃; CTE increases significantly above the Curie point (230℃).

? Processing Deformation: Cold deformation can further reduce CTE, but annealing is required to restore ductility.

VII. Supply & Certification? Common Forms: Plates, strips, coils, forgings; custom cutting available.

? Certification Support: Provide material certificates compliant with ASTM, EN, etc.; third-party flaw detection reports available from some suppliers.

For specific models or supplier information, please contact material manufacturers (e.g., Muyan Alloy, Shanghai Kangdeli) directly for the latest quotations and inventory status.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Haynes 188 Forgings - Oxidation Resistant, Gas Turbine Combustors | Industrial Superalloy Forgings

-

Marine Monel 400 Forgings - Saltwater Resistance, Seawater Valves | Durable Nickel Alloy Parts

-

Marine Monel 400 Forgings - Saltwater Resistance, Seawater Valves

-

Nickel Alloy Rod/Bar High Wear-resistant And High Toughness Alloy

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar Stock

-

Titanium Pipe Fitting Titanium Elbow/ Ti Elbow/Alloy Titanium Elbow

-

Titanium Alloy Steel Ta2 Ta8 Ta10 Pipe Fitting Bend Long Radius Elbow for Car Modified Used

-

ASTM B363 45/90/180 Titanium Elbow Pipe Fitting Alloy Titanium Elbow

-

Factory Sells High Quality Customized Titanium Elbow in Stock

-

Titanium Stainless Steel Pipe Fittings 90 Degree Elbow

-

Stainless Steel Elbow for Car Exhaust System Titanium Alloy Pipe Bends Tube

-

High-Quality Titanium 90 Degree Elbow Pipe Fittings for Corrosion Resistance

-

High Quality Industrial Pipe Fittings 45/90/180 Degree Seamless Welded Titanium Elbow

-

Gr5 Titanium Exhaust Pipe 45 Degree Polished 316 Stainless Steel Pipe Elbow

-

Titanium Mandrel Bends 90 Degree Titanium Elbow for Exhaust Titanium Pipe Elbow Fittings

-

Reliable Titanium Fittings With Long Service Life for Petrochemical, Oil And Gas Pipeline Networks

-

Cheap Price of Factory Custom Titanium Elbow Gr2 Seamless Elbow120 And 90 And 45 Degree

-

Mirror Polished High-Gloss Food-Grade Elbow TA2 Titanium Alloy Elbow

-

Manufacturer of TA2 Titanium Alloy Elbows, Flanges And Other Pipe Fittings

-

Titanium Pipe Fittings 45 90 180 Degree Exhaust Welded Bend Elbow

-

Industry Used Gr5 Titanium Rod 8mm 10mm 30mm 40mm Tc4 Titanium Alloy Bar Grade 5 Titanium Rod Ti6al4V

-

High Quality Wholesale Titanium Tube Tc2 Titanium Alloy Rod

-

Premium Heat-Resistant Gr5 Tc4 Titanium Rod for Industrial Use

-

ASTM F136 Ti-6ai-4V Tc4 Price of 1kg Round/Square Titanium Alloy Bar / Rod China Manufacturers

Popular Searches

- powder coating

- stainless steel

- centrifugal pump

- wire netting

- chain link fence

- link chain

- twisted rope

- netting

- water meter

- fiberglass cloth

- galvanized wire mesh

- high tenacity

- load cell

- pvc coating

- floor scale

- polyvinyl

- submersible sewage pump

- acid pump

- nickel chrome wire

- alloy plate

- welded panel

- centrifugal submersible sewage pump

- high temperature resistant

- extruded plastic mesh netting

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Sheet & Plate

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile