powder coating Insights & Buyer's Guide

The introduction of powder coating has surfaced technology advancements in finishing and coating surfaces, providing protective finishing that is long-lasting, visually attractive, and eco-friendly. While delving deeper into the powder coating industry, you will encounter different options designed for your requirements, such as increasing the lifespan of metallic surfaces or creating a shiny, colorful look. This guide outlines all the necessary information concerning coating systems, starting with the procedure’s fundamentals and advantages, indicating why it’s preferred over conventional methods, to choosing the right one for your project.

What is Powder Coating and How Does it Work?

Understanding the Powder Coating Process

The introduction of powder coating in North America during the 1960s marked a tremendous growth in the finishing processes, and it still continues to flourish. It constitutes more than 15% of the overall industrial finishing market share. The procedure includes applying a dry mixture made of powder and resin, and pigment to a surface. Electrostatic spray guns are used to apply the powder, which charges the particles of powder, allowing them to stick to the grounded surface. The coated items are put into curing ovens, where heat is applied to transform the coating into a smooth, hard finish. The lack of use of solvents makes this method more effective and eco-friendly.

Types of Powder Coating Methods

Different types of powder coating methods exist to match various applications and materials. They can be classified into two categories: thermoset and thermoplastic powder coatings. Thermoset powders provide a stronger coating with increased heat and chemical resistance compared to thermoplastic powders, which flow and liquefy when heated but remain unchanged chemically. Pyrolytic lacquer applications needing thicker coatings are best suited with thermoplastic powders. Knowing the difference is very important for your project.

The Role of Electrostatic Charge in Powder Coating

Electrostatic charge plays an important role when it comes to the coating of the powder. During the application of the dry powder onto a surface, the spray gun generates an electrostatic charge. Because of this charge, the powder particles will stick to the surface without any gaps. Electrostatic attraction holds the powder in place and guarantees a high-standard coating, which minimizes waste. Use of this method enhances the effectiveness of the coating procedure while improving the product’s coating appearance and increasing its durability.

Why Choose Powder Coating Over Traditional Spray Paint?

Advantages of Powder Coating Finishes

Compared to conventional spray paint, coating finishes have more pros. Perhaps the greatest advantage is its durability. The finish of the coating is fade-resistant to chipping, scratching, and even fading. Moreover, liquid paints fail to provide a uniform coating. However, with powder coating, this problem is solved. With the absence of VOCs, powder coating emerges as a safer alternative while having a lower environmental impact.

Comparing Coating Materials: Powder vs. Liquid Paint

The contrasts between powder coating and liquid paint are obvious. Liquid paints usually have solvents and VOCs, which are both environmentally and human-harmful. On the other hand, dry powder applied powder coatings require no solvents. This makes powder coatings more eco-friendly and liquid coatings more economical due to less waste and higher transfer efficiency. Furthermore, a wider selection of finishes and textures more flexible designs compared to other coatings.

Environmental Benefits of Powder Coating

Compared to other finishing processes, surface finishing with powder coating is much more eco-friendly. Contrary to liquid paints, which contain VOCs and hazardous air pollutants, powder coatings do not release significant amounts of VOCs. Additionally, the overspray generated from powder coating can be captured and reused, which minimizes waste and makes the approach more sustainable. Choosing powder coating also means getting a quality finish while helping improve the surroundings.

How to Choose the Right Type of Powder for Your Project?

Factors to Consider in Choosing Powder Coating

Choosing specially formulated powder for your project entails contemplating the intended use of the coated item, the coating’s environment, and the required finish. Take outdoor applications as an example. They not only need the powder to enhance aesthetic features but also to be UV resistant. Indoor applications have their own aesthetic needs. It is also very essential to keep the substrate material in mind since different powders adhere to different surfaces. You can always contact a powder coating expert to guide you in the selection process.

Exploring Different Types of Powder Coating Materials

Different powder coating materials are available, and each of them has its unique pros and cons. These include epoxy, polyester, and polyurethane powders. Epoxy powders have great adhesion and chemical resistance, which makes them very useful for industrial applications. Polyester powders are great for outdoor usage as they have better weather resistance. Polyurethane powders give a smooth and glossy finish, which is great for decorative use. Knowing these options will better help you select a material fitting for your project.

Matching Powder Coating Finishes to Your Needs

Every powder coating project requires a flawless finish, and with powder coating, you can achieve a matte, satin, or high-gloss finish. Selecting the type of coating not only alters the aesthetics but also impacts its functionality. A matte finish conceals blemishes and imperfections on the surface while gloss finishes expose surface damages but heighten vibrancy. Customized finishes matched to the project's requirements ensure durability and optimum performance in its environment.

What are the Steps in the Powder Coating Application Process?

Preparing the Surface for Powder Coating

The correctly conducted steps of Surface Preparation In The Application of Powder Coating Techniques In The Engineering Processes ensure the preservation of the coating matters over time. Throughout the process, proper cleaning procedures involve surface grease elimination, abrasive blasting, or chemical roughening for substance addition. Surface smoothing impacts the success ratio of the powder coating effectiveness achieved throughout blends.

Applying the Powder with a Spray Gun

The infusion of powder coating is done using a spray gun, which coats the surface with the powder. The spray gun also gives an electrostatic charge to the powder particles, which ensures an even distribution on the surface. This method gives complete control of the coating thickness and uniformity, providing a professional-grade finish. This method is economical due to its efficient use of resources when using a spray gun, as well as its low coating wastage.

The Curing Process: How Heat Transforms the Coating

Curing is the last stage in the application process of coating with powder. Once the coating has been applied, the coated part is put in a curing oven where it is exposed to high temperatures. Heat causes the powder to melt, and the melted powder is plasticized to a film which flows and sticks on the surface uniformly. Effective curing is important to ensure that the coating is transformed into a firmly bonded, durable coating that can withstand weathering. The finish not only looks attractive but also exceedingly tough.

Frequently Asked Questions(FAQs)

Q: What is a powder coating system, and how does it work?

A: A powder coating system is a dry finishing process that involves applying a fine powder to a surface using an electrostatic process. The powder is then heated to form a smooth, durable finish. This system is widely used in various industries due to its efficiency and eco-friendliness, as powder coatings contain no solvents.

Q: How does the electrostatic coating process contribute to powder coating work?

A: The electrostatic coating process is crucial in powder coating work as it ensures that the powder particles adhere evenly to the surface being coated. The charged powder particles are attracted to the grounded object, allowing for uniform coverage and minimizing excess powder.

Q: What are the benefits of using powder coating services over traditional painting methods?

A: Powder coating services offer several advantages over traditional painting, including a more durable finish, a range of colors, and a more environmentally friendly process. Unlike paint, powder coatings contain no volatile organic compounds, making them a safer choice for both workers and the environment.

Q: What types of powder are used in powder coating systems?

A: The powders used in powder coating systems typically include thermoset powder coatings and thermosetting powder, which are both known for their durability and resistance to chipping, scratching, and fading. Additionally, UV-curable powder coatings are available for applications requiring rapid curing times.

Q: How can I ensure that my powder coating system is suitable for commercial powder coating?

A: To ensure your powder coating system is suitable for commercial powder coating, consider factors such as the size of the parts being coated, the type of powder coating gun used, and the capacity of your finishing systems. Consulting with a professional or the Powder Coating Institute can provide valuable guidance.

Q: How is excess powder managed in a powder coating system?

A: Excess powder in a powder coating system is typically collected and recycled to minimize waste. The system is designed to capture overspray, allowing the powder to be reused in future applications, which enhances efficiency and reduces costs.

Ral 7008 Khaki Grey Electrostatic powder coatingUS$ 1 - 9MOQ: 1 KilogramGusu District Qiusheng Commercial Equipment firm1 YR

Ral 7008 Khaki Grey Electrostatic powder coatingUS$ 1 - 9MOQ: 1 KilogramGusu District Qiusheng Commercial Equipment firm1 YR Color White Plastic Parts Bin powder coating Plastic PartsNegotiableMOQ: 1 PieceShijiazhuang Junzhu Technology Co., Ltd1 YR

Color White Plastic Parts Bin powder coating Plastic PartsNegotiableMOQ: 1 PieceShijiazhuang Junzhu Technology Co., Ltd1 YR Professional powder coating Gun Electrostatic Powder Spray Paint EquipmentNegotiableMOQ: 10 PiecesYueqing Ruichen electronic Co., LTD1 YR

Professional powder coating Gun Electrostatic Powder Spray Paint EquipmentNegotiableMOQ: 10 PiecesYueqing Ruichen electronic Co., LTD1 YR PEI Plastic Material Powder Coated Pei Polyethylenimine Pei Ultem 1100US$ 20 - 30MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS

PEI Plastic Material Powder Coated Pei Polyethylenimine Pei Ultem 1100US$ 20 - 30MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS China Factory Hot Popular Customized Security Fence Wire Mesh Powder Coated Chain Link Boundary FencingNegotiableMOQ: 100 Square MetersAnping Dingdian Wire Mesh Products Co., Ltd.1 YR

China Factory Hot Popular Customized Security Fence Wire Mesh Powder Coated Chain Link Boundary FencingNegotiableMOQ: 100 Square MetersAnping Dingdian Wire Mesh Products Co., Ltd.1 YR 3003041-D598 Steering Arm for FAW J6 Truck - Forged Steel with powder coatingUS$ 5.5 - 50MOQ: 1 PieceHS Electrical Technology Co,LTD3 YRS

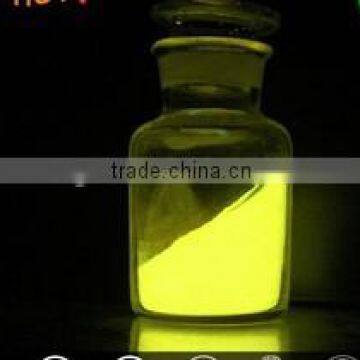

3003041-D598 Steering Arm for FAW J6 Truck - Forged Steel with powder coatingUS$ 5.5 - 50MOQ: 1 PieceHS Electrical Technology Co,LTD3 YRS New fluorescent powder coatingsUS$ 2 - 4MOQ: 1000 GramsLongkou Unity Machinery Equipment Co., Ltd.5 YRS

New fluorescent powder coatingsUS$ 2 - 4MOQ: 1000 GramsLongkou Unity Machinery Equipment Co., Ltd.5 YRS Polyethylene Type powder coatingNegotiableMOQ: 1 SetNingbo Huaxiang Import & Export Co., Ltd.5 YRS

Polyethylene Type powder coatingNegotiableMOQ: 1 SetNingbo Huaxiang Import & Export Co., Ltd.5 YRS pvc powder coated trunkingUS$ 0.1 - 20MOQ: 1000 MetersHebei Kunzan Plastic Product Co., Ltd.5 YRS

pvc powder coated trunkingUS$ 0.1 - 20MOQ: 1000 MetersHebei Kunzan Plastic Product Co., Ltd.5 YRS Hanging Hook for powder coatingUS$ 0.003 - 0.05MOQ: 5000 PiecesHangzhou Jiangnan Spring Co., Ltd.5 YRS

Hanging Hook for powder coatingUS$ 0.003 - 0.05MOQ: 5000 PiecesHangzhou Jiangnan Spring Co., Ltd.5 YRS powder coating equipmentUS$ 75,000 - 950,000MOQ: 1 SetHenan Machinery & Equipment Company Limited5 YRS

powder coating equipmentUS$ 75,000 - 950,000MOQ: 1 SetHenan Machinery & Equipment Company Limited5 YRS powder coating MachineUS$ 450 - 900MOQ: 1 SetHangzhou Huashengtong Machinery Equipment Co., Ltd.5 YRS

powder coating MachineUS$ 450 - 900MOQ: 1 SetHangzhou Huashengtong Machinery Equipment Co., Ltd.5 YRS powder coating aluminium tubeUS$ 1 - 3,500MOQ: 1 TonFoshan Nanhai Meixia Aluminium Co., Ltd.5 YRS

powder coating aluminium tubeUS$ 1 - 3,500MOQ: 1 TonFoshan Nanhai Meixia Aluminium Co., Ltd.5 YRS powder coating watering can.US$ 0.2 - 10MOQ: 2000 PiecesShandong Shengyang Household Electrical Appliances Co., Ltd.5 YRS

powder coating watering can.US$ 0.2 - 10MOQ: 2000 PiecesShandong Shengyang Household Electrical Appliances Co., Ltd.5 YRS powder coating book shelfUS$ 120 - 190MOQ: 50 UnitsLuoyang Hefeng Office Furniture Co., Ltd.5 YRS

powder coating book shelfUS$ 120 - 190MOQ: 50 UnitsLuoyang Hefeng Office Furniture Co., Ltd.5 YRS Powder Coated Offset BlocksUS$ 80 - 120MOQ: 20 TonsTangshan Bencheng Science & Technology Co., Ltd.5 YRS

Powder Coated Offset BlocksUS$ 80 - 120MOQ: 20 TonsTangshan Bencheng Science & Technology Co., Ltd.5 YRS powder coating Dutch OvenUS$ 1 - 5MOQ: 1000 PiecesZhejiang Weinuo Industry & Trade Co., Ltd.5 YRS

powder coating Dutch OvenUS$ 1 - 5MOQ: 1000 PiecesZhejiang Weinuo Industry & Trade Co., Ltd.5 YRS Manual powder coating Machine / Electrostatic powder coating MachineUS$ 590 - 990MOQ: 1 SetZhengzhou Hento Machinery Co., Ltd.5 YRS

Manual powder coating Machine / Electrostatic powder coating MachineUS$ 590 - 990MOQ: 1 SetZhengzhou Hento Machinery Co., Ltd.5 YRS Machine For Automatic powder coating LineUS$ 1,700 - 3,000MOQ: 1 SetHongjing Test Instrument Co., Ltd.5 YRS

Machine For Automatic powder coating LineUS$ 1,700 - 3,000MOQ: 1 SetHongjing Test Instrument Co., Ltd.5 YRS powder coating filter element CartridgesUS$ 35 - 45MOQ: 20 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

powder coating filter element CartridgesUS$ 35 - 45MOQ: 20 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS White powder coating Curtain RodsUS$ 1.6 - 8.6MOQ: 200 PiecesHangzhou Baihong Hardware Co., Ltd.5 YRS

White powder coating Curtain RodsUS$ 1.6 - 8.6MOQ: 200 PiecesHangzhou Baihong Hardware Co., Ltd.5 YRS Powder coated aluminum glass doorsUS$ 300 - 600MOQ: 30 Square MetersHwarrior Curtain Wall Engineering (Guangzhou) Co., Ltd.4 YRS

Powder coated aluminum glass doorsUS$ 300 - 600MOQ: 30 Square MetersHwarrior Curtain Wall Engineering (Guangzhou) Co., Ltd.4 YRS powder coating spray valve with actuatorUS$ 0.03 - 0.06MOQ: 200000 PiecesYanshan Jinxing Aerosol Valve Manufacture Co., Ltd.5 YRS

powder coating spray valve with actuatorUS$ 0.03 - 0.06MOQ: 200000 PiecesYanshan Jinxing Aerosol Valve Manufacture Co., Ltd.5 YRS