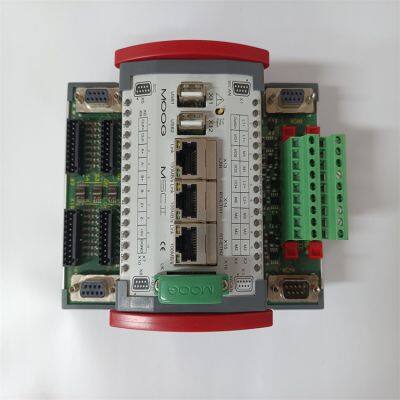

MOOG D136-002-005 with D138-002-002 Dongle Motion Controllers

- T/T Western Union

You May Like

Product Details

| Brand Name | MOOG | Model Number | D136-002-005 |

Product Description

Features High-performance Computing: Based on the MPC5200 hardware platform, it has sufficient CPU performance to run PLC tasks in the background. It can achieve fast and precise closed-loop control, and is suitable for multi-axis motion control scenarios with high requirements for control accuracy and response speed. Multiple Communication Interfaces: It is equipped with two independent CAN/CANopen interfaces, supporting a communication rate of 10kbit/s to 1Mbit/s. It also has optional fieldbus interfaces such as Ethernet real-time host and Profibus-DP slave station, which is convenient for data exchange and communication with other devices, and can be flexibly integrated into various industrial automation systems. Configurable Interfaces: In the MACS development environment, the input/output interfaces, sensor interfaces, and expansion module interfaces can all be flexibly configured. Customized settings can be made according to different application requirements, adapting to a variety of industrial control scenarios. High-reliability Design: It complies with the electromagnetic compatibility CE standard, meets relevant requirements such as EN 61000-6-4/EN 61000-6-2, and has the ability to resist shock and vibration, enabling stable operation in harsh industrial environments. At the same time, it has a watchdog function. When an error occurs, all digital and analog outputs will be disabled by hardware, and additional digital outputs are provided for monitoring to ensure the safety and stability of the system. Easy Maintenance: It has no vulnerable components such as fans or batteries, and does not require regular maintenance, reducing maintenance costs and downtime.

Functions Multi-axis Motion Control: It can perform calculations for multi-axis motion control, achieve closed-loop control of the position, speed, pressure/force of the hydraulic and electrical axes, and evaluate the signals from position sensors. It is suitable for industrial automation equipment that requires precise control of multiple motion axes, such as robots and numerically controlled machine tools. PLC Function Integration: It integrates PLC functions and can implement various complex control logics through programming, meeting the control requirements of different industrial production processes, reducing the use of external PLC devices, and lowering the cost and complexity of the system. Data Exchange: Through fieldbus or Ethernet, it can exchange data with any type of device (such as monitors, control stations, etc.), facilitating operators to monitor the running status of the system in real time, and also enabling remote control and centralized management.

Technical Parameters Power Supply: DC power supply of 24V DC (18-32V), which is a safety extra-low voltage. The typical module consumption is 0.5A when supplied separately, and the maximum module consumption of the digital 24V output is 2A. Closed-loop Cycle Time: It is 0.1 milliseconds for 2-axis PID control and 0.2 milliseconds for 2-axis composite loop and PLC control, which can quickly complete control calculations and output updates, achieving real-time control of the motion process. Environmental Conditions: The ambient temperature range is from +0°C to +50°C, meeting the temperature requirements of general industrial environments.

Application Areas Industrial Automation: In equipment such as automated production lines and robots, it is used to precisely control the position, speed, and force of multiple motion axes, achieve complex actions and tasks, and improve production efficiency and product quality. Power Industry: It can be used for the motion control of power equipment, such as the speed regulation system of generators and the operating mechanism of switchgear, ensuring the stable operation of the power system and the reliable operation of the equipment. Other Fields: In industries such as metallurgy, papermaking, textiles, and chemicals, it can also be applied to various equipment and processes that require precise motion control, such as continuous casters in the metallurgy industry and paper winders in the papermaking industry.

The MOOG D136-002-005, as a motion control controller, its installation needs to follow certain specifications and procedures to ensure the normal operation of the equipment and the safety of use. The following is an introduction to the general installation method:

1. Preparation Before Installation Confirm the Installation Environment: Ensure that the ambient temperature at the installation location is between +0°C and +50°C, which meets the environmental requirements of the equipment. At the same time, ensure that the installation location is dry, well-ventilated, and far away from strong electromagnetic interference sources, corrosive gases, and liquids to avoid affecting the performance and lifespan of the equipment. Prepare Installation Tools: Prepare necessary installation tools, such as screwdrivers, wrenches, etc. Check the Integrity of the Equipment: Before installation, carefully check whether the MOOG D136-002-005 and its accessories are complete and whether there is any damage to the appearance. If there are any problems, contact the supplier or the manufacturer in a timely manner for handling.

2. Selection of the Installation Location Select an Appropriate Installation Location: Select an appropriate installation location to ensure that the equipment has enough space for installation and heat dissipation. At the same time, consider the convenience of operation and maintenance of the equipment, and reserve enough space for connecting cables and debugging. Fix the Equipment: According to the installation holes of the equipment, use suitable screws to fix the MOOG D136-002-005 on the installation plate or control cabinet. Ensure that the equipment is installed firmly and will not shake or vibrate during operation.

3. Power Connection Disconnect the Power Supply: Before connecting the power supply, be sure to disconnect all relevant power supplies to ensure the safety of the operation. Connect the Power Cable: According to the power requirements of the equipment, use a suitable power cable to connect the 24V DC power supply (18 - 32V) to the power interface of the MOOG D136-002-005. Pay attention to the correct connection of the positive and negative poles of the power supply to avoid damaging the equipment due to reverse connection. Check the Power Connection: After the connection is completed, carefully check whether the power cable is firmly connected and whether there are any loose or poor contact situations.

4. Communication Interface Connection Select the Communication Method: According to the actual application requirements, select a suitable communication interface (such as CAN/CANopen, Ethernet, Profibus-DP, etc.) for connection. Connect the Communication Cable: Use the corresponding communication cable to connect the communication interface of the MOOG D136-002-005 with the communication interfaces of other devices (such as controllers, monitors, control stations, etc.). Ensure that the connection of the communication cable is correct and meets the requirements of the corresponding communication protocol. Set the Communication Parameters: According to the communication protocol and actual application requirements, set the communication parameters of the MOOG D136-002-005, such as the baud rate, node address, etc. Ensure that the communication parameters between the devices are consistent for normal communication.

5. Input/Output Interface Connection Connect the Sensors and Actuators: According to the actual application requirements, connect various sensors (such as encoders, position sensors, etc.) and actuators (such as servo motors, solenoid valves, etc.) to the input/output interfaces of the MOOG D136-002-005. Ensure that the connection is correct and the signal transmission is stable. Check the Connection: After the connection is completed, carefully check whether the input/output interface connection is firm and whether there are any loose or poor contact situations. At the same time, check whether the working status of the sensors and actuators is normal.

6. Grounding Connect the Grounding Wire: In order to ensure the safe operation of the equipment and prevent electromagnetic interference, connect the grounding terminal of the MOOG D136-002-005 to a good grounding device. The grounding wire should use a suitable specification and material to ensure that the grounding resistance meets the requirements.

7. Inspection After Installation Check All Connections: After the installation is completed, carefully check whether all the connection cables are firmly connected and whether there are any loose or poor contact situations. Check the Equipment Status: Turn on the power supply and check whether the indicator lights of the MOOG D136-002-005 are normally on and whether the equipment can be started normally. If there are any abnormal situations, check and troubleshoot the faults in a timely manner.

Contact Us

- Guizhou Yuanmiao Automation Equipment Co., Ltd.

- Contact nameAva Chat Now

- AddressHongshan Hotel, No. 42, Hongshan Lake Road, North Street, Xixiu District. Doubletree by Hilton) Building 14 Floor 9, Anshun, Guizhou

Product Categories

| ABB | GE Fanuc | Triconex | Bently Nevada |

| Woodward | HIMA | HONEYWELL | ICS Triplex |

| MOOG | FOXBORO | NI | Emerson |

| Other brands |

New Products

-

HIMA F8652X Central Module

-

Enterasys A4H124-24TX P0973JM Ethernet Switch

-

Enterasys A4H254-8F8T P0973JP Ethernet edge switch

-

Foxboro FBM201e P0924TR Analog Input Interface Module

-

Foxboro FBM223 P0917HD Fieldbus Interface Module

-

Foxboro FBM219 P0916RH Discrete I/O Module

-

Foxboro FCP270 P0917YZ Field Control Processor

-

Foxboro P0922YU FPS400-24 Power Supply Module

-

Bently Nevada 3500/05-01-02-00-00-01 System Rack

-

Bently Nevada 3500/15 106M1079-01 Universal AC Power Supply

-

Bently Nevada 3500/22M 288055-01 Transient Data Interface Module

-

Bently Nevada 3500/42M 176449-02 Proximitor/Seismic Monitor

-

Bently Nevada 3500/50M 288062-02 Tachometer Module

-

Bently Nevada 3500/92 136180-01 Communication Gateway Module

-

Bently Nevada 3500/32M 149986-01 4-Channel Relay Module

-

Bently Nevada 3500/25 184684-01 Enhanced Keyphasor Module

-

Bently Nevada 3500/93 135785-02 System Display

-

Bently Nevada 125720-01 Channel Relay Module 3500/32M

Popular Searches

- power inverter

- solar energy

- remote control

- solar power

- solar system

- solar charger

- remote controller

- temperature controller

- temperature sensor

- game controller

- temperature control

- joypad

- gamepad

- speed controller

- motor controller

- pressure controller

- universal remote

- remote switch

- solar controller

- Solar Charger Controller

- Mppt Solar Charger Controller

- digital temperature controller

- solar regulator

- solar charge controller

- Mould Temperature Controller

- Water Pump Controller

Recommended Products

- ABB AIN220 P-HB-AIN-22010000

- ABB DOT100 P-HB-DOT-10010000

- ABB SPAU130C-AA SPAU 130 C-AA

- ABB SPAU320C1-AA SPAU 320 C1-AA

- ABB SACO16D1-AA SACO 16D1-AA

- ABB DIO400 / P-HB-DIO-40010000

- ABB AIN300 P-HB-AIN-30010000

- ABB DI831/DP840

- ABB SD812V1/3BSC610045R2

- ABB A1810/3BSE008516R1

- ABB CP-S 24/10.0

- ABB DSTD 195/3BSE004724R1

Find Similar Products By Category

- Electrical & Electronics > Power Transmission & Transformer > Transformer

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Ava

Hi there! Welcome to my shop. Let me know if you have any questions.

Ava

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile