Home > Products > CCD tester > AITOP High quality CCD Positive Negative Battery Pack Tester Lithium Battery Production line

AITOP High quality CCD Positive Negative Battery Pack Tester Lithium Battery Production line

- 100 Set / Sets per Month

- shenzhen

- T/T

- 15 days

You May Like

-

ultrasonic aluminum wire bonding machine Manual wire bonder

-

AITOP Lithium Battery Pack Test System Charging Discharging Cabinet battery pack testing tester Aging Machine

-

Aitop 60v 10a Charge 20a Discharge Lithium Battery Aging Tester 100v 60AMulti-Function Lithium Battery Pack Test System Charging Discharging Cabinet

-

Aitop 60v 10a Charge 20a Discharge Lithium Battery Aging Tester 100v 60AMulti-Function Lithium Battery Pack Test System Charging Discharging Cabinet

-

Aitop Lithium Battery Pack Charge And Discharge Machine Equipment Aging Tester Testing Cabinet

-

AITOP-5V30A-08CH 5v 6a battery 18650/26650/32650 5v3a 512ch 32650 18650 battery capacity grading Capacity Tester machine

Product Details

| Place of Origin | China | Certification | ce | |

| After-sales Service Provided | Engineers available to service machinery overseas | Warranty | 1 year | |

| Condition | New | Voltage | 220v/380v | |

| Usage | for li-ion battery pack welding welder | Power(W) | 150kg | |

| Motor Type | AC Motor | Dimensions | 1800*920*1940mm | |

| Rated Duty Cycle | aitop | Pilot Arc Current | 5000A/800A/10000A |

Product Description

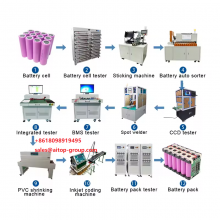

CCD Tester Battery Cell Positive And Negative Tester & Battery Pack Welding Testing Equipment

Why CCD Detection Equipment is Very Important in the Production of Lithium Battery Packs

In the production of lithium battery packs, CCD detection equipment plays a crucial role for the following reasons:

Firstly, it can accurately detect various defects and abnormalities on the surface of lithium battery cells, such as scratches, dents, and foreign matter. This helps to ensure the quality and integrity of the battery cells and reduces the risk of potential safety hazards.

Secondly, CCD detection equipment can precisely measure the dimensions and geometries of the battery cells, ensuring that they meet the required specifications. This is essential for the proper assembly and performance of the lithium battery pack.

Moreover, it can monitor the consistency and uniformity of the battery cells, helping to identify any inconsistent or substandard cells that might affect the overall performance and lifespan of the battery pack.

It also enables real-time detection and feedback, allowing for immediate adjustments and improvements in the production process to maintain high quality standards.

Furthermore, with the increasing demand for high-quality and reliable lithium battery packs in various industries, CCD detection equipment provides an effective means to ensure the quality and reliability of the final products, enhancing the competitiveness of the manufacturers.

In summary, CCD detection equipment is of great significance in the production of lithium battery packs, as it helps to guarantee the quality, performance, and safety of the batteries, and promotes the development and application of the lithium battery industry.

TOP Battery machine factory contact number

Shenzhen AITOP Intelligent Equipment Co., Ltd.

Email :sales(@)

wehcat/whatsapp /Phone :008618098919495/008618435204981/18098989643

+8618820281861

CCD Tester Battery Cell Positive and Negative Tester & Battery Pack Welding Testing Equipment

1. Function description

CCD solder joint detector is an automatic equipment for lithium battery processing, which has the functions of automatic positive and negative pole detection, positive and negative solder joint detection, solder joint defect differentiation, automatic discharge, etc.

2. Process flow

Feeding and positioning of electric core → positive and negative pole detection → positive and negative solder joint detection (CCD) → NG automatic sorting → OK automatic discharging

3. Mechanical structure

1) Feed positioning of battery core

2) Polar ear leveling

3) CCD solder joint detector has high resolution image acquisition, artificial intelligence image processing and recognition technology to improve defect recognition rate

4) CCD welding detector has the advantages of fast recognition speed and high accuracy. It can select anti-static belt without damaging the battery

5) Humanized programming, easy to learn and understand.

4. Specifications

XY axis stroke | 500mm (customizable) |

Motor drive speed | 300 mm / s |

Operating system | industrial computer + intelligent camera |

Transmission mode | assembly line |

Driving mode | stepping motor |

Repeated positioning accuracy | ± 0.1mm |

Detection efficiency | 1s / pcs |

Overall power | 500W |

Total weight | 150kg |

Maximum bearing weight | 30kg |

Input power | single phase AC 220V / 50Hz |

Air source | 0.5-0.6mpa |

Size | 960 * 950 * 1800mm |

5. Equipment configuration list

● touch screen: Wellington

● PLC: motion controller

● step motor: Bifu

● servo motor: Mitsubishi & lechuang

Sensors: Panasonic and OMRON

● bearing: Japan NSK

● cylinder: Adec

● switching power supply: Mingwei, Taiwan

Product description:

The lithium-ion battery pack welding quality inspection machine is used to detect fake welding and missing welding of battery packs, and provides guarantee for the quality of battery pack welding.

Scope of application:

This battery pack welding quality inspection machine is suitable for the rapid inspection of the welding reliability of lithium-ion battery packs of ultrasonic welding equipment & wire bonding machine, including 18650 battery module and 21700 battery module.

Brief introduction of the battery pack inspection equipment

Product name | Battery Pack Welding Quality Inspection Machine |

Product model | AITOP-930 |

Applicable modules | 18650 battery module: 540*340mm |

21700 battery module: 968*314*86mm | |

21700 battery module: 657*314*88mm | |

Customizable | |

Test speed | ≤6~12min/side |

Gas nozzle distance | The distance between the gas nozzle and the welding point: <10~18mm |

Blowing force | 230~300g |

Detection accuracy | Missed detection: 0% |

False detection:<0.5% | |

Test pins life | >300,000 times |

Current accuracy | ±(0.05%FS+0.05%RD) |

Data recording time | ≥100ms |

Software function | Support cyclic working condition file import test function |

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/

008618435204981/18098989643/+8618820281861

Email:sales(@)

Our other product catalogues

Packing and shipping

*Be Packed by Wooden Box

*Lead Time: Standard Machine: 7-10 working days after we received your battery pack samples.

*Customized Machine: 30-35 days

Our Service

Pre-sales

1) Inquiry and consulting support. All will be replied in 12 hours.

2) View our Factory and testing the machine, demonstrate how the machine work.

After-Sales

1) Training how to install the machine, training how to use the machine.

2) Engineers available to service machinery overseas

3) 1-year guarantee ( free maintain in a year)

4) Replacement parts and other accessories provided

FAQ

Q: What can your machines do?

A: Make the batteries production automatically.

Save the factory owner's invest and better the efficiency.

Q: What kind of items can your machines produce?

A: Our machines can be used to produce batteries for Power Bank, Laptops, Cell Phones and Ebikes, etc.

Q: How can I see samples or know more about the machines?

A: We have real time video on Youtube.

Please contact our sales to get the links.

Indian friends can visit our New Delhi sales office and see the machine by yourselves.

Q: Do you have a MOQ for orders?

A: Customers are free to buy our production line (3-5 machines altogether) or just 1 single machine.

Our factory MOQ is 1 set.

Q: Do you have any warranty or certifications?

A: We provide 12 months warranty for the machine, and life-time after-sales maintenance.

All of our products are with CE certifications and are good to export worldwide.

Q: I am a new factory owner. Can I get some advices about automatic production?

A: You can tell us the ideal turn-over you want for your new factories.

Our professional engineers and sales shall provide you with budget and costs how much it takes.

Looking forward to establish good business relationship with you

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981/18098989643/

+8618820281861/+8618098919495

Email:sales(@)

Contact Us

- Shenzhen AITOP Intelligent Equipment Co. LTD

- Contact nameDavid xiao Chat Now

- Phone86-180-98919495

- AddressbaoanDistrict, Shenzhen, Guangdong

Product Categories

New Products

-

Aitop Battery Capacity Tester 5V 20A 30a 60a 100A 120a Prismatic Battery Cells Charging Discharging Life Cycle Testing

-

Aitop 5v30a Pristmatic Battery Formation Machine Cell Grading Machine Testing Equipment For prismatic Cell Pack Assembly Charging Discharging Life Cycle Testing

-

Lithium Battery Pack 1-24 Series Protection Board High Precision Bms Analyzer Tester With Pc BMS Tester 1-32 Series

-

Battery Automatic Pulse Laser Cleaning Machine For Prismatic Battery Pack Automatic Assembly Line

-

220v automatic voltage stabilizer 5KW10KW20KW30KW40KW15KVA single-phase high power program adjustable DC power supply

-

CYLINDRICAL battery CELL SORTING & STICKER PASTING MACHINES + 10CH 18650 / 21700 / 26650 / 32700 SORTING MACHINE WITH BARCODE

-

BMS Tester 10S/16S/20S/1-24S/32S 48sLithium Battery Management System Test Equipment

-

BMS Tester 10S/16S/20S/1-24S/32S 48s Ebike Lithium Battery Pack Protective Plate 1-24 Series BMS PCB Tester Testing System BMS Tester

-

Automatic Battery Pack/Ultrasonic Aluminum Spot Welder/ Wire Pressure Welder/18650 21700 Lithium Batteries/Wire Bonding Machine

-

The Latest High-Power Battery Tester 5V30A/Optional Other Models 5v10a 20a 60a 100a Battery Charge Discharge Machine

-

The Latest 5V30A High-Precision Tester for Battery 5v10a 20a 60a 100a Battery Charge Discharge Machine

-

5 Channels Cylindrical Battery Automatic Sorting Machine for 18650,21700, 26650, 32650

-

AITOP machine is used for 18650,26650,32650 cylinder Motorbike battery pack automatic spot welding

-

AITOP 5v6a feedback energy saving regeneration 18650 Cycler tester 256CH 512ch 5V10A 33140 Lithium Battery Cell Testing Capacity tester

-

AITOP Single & Double Side Spot Welding 18650,26650,32650 Motorbike battery pack automatic spot welder

-

SORTING MACHINE10ch GRADES SORTING MACHINE FOR 32140 CELLS HIOKI TESTER HIOKI3562 SCANNER KEYENCE

-

32140 Battery Cell Voltage Tester Machine 3265018650 21700 Battery Testing Automatic Battery IRTester

-

reliable battery tester technology AITOP-PFX 6CH prismatic cell sorting machine battery manufacturing cell sorter

-

Revolutionize Battery Manufacturing with AITOP-PFX 6CH - Trusted Cell Sorter with Reliable Technology

-

Aitop Prismatic Battery Manual Stacking Strapping Pressing Machine for Prismatic Battery Automatic Assembly Line

-

Aitop Prismatic Battery Stacking Strapping Pressing Machine for Prismatic Battery Automatic Assembly Line

-

Automatic 10 Channels Lithium Ion Battery Sorting Machine Prismatic Cell Sorter for Prismatic Battery Voltage IR Sorting tester

-

Cylinder 40135 33135 32140/33140 Li ion Battery 5 Channels Battery Sorting Machine

-

Automated PVC Shrink Wrapping Solution for Single - Cell & Battery Pack Packaging

Popular Searches

- Arc Welders

- welding equipment

- inverter welder

- tig welder

- mma welder

- mma welding equipment

- dc welder

- arc welding

- Inverter Arc Welder

- Welding Machine Welder

- Mig Welder

- Stick Welder

- Mma Arc Welder

- Mma Inverter Welder

- Argon Arc Welder

- Welding Equipment Welder

- hydrogen equipment

- MIG Welders

- mig/mag

- mig welding equipment

- mig welding machine

- Inverter Mig Welder

- Arc Welder

- Mag Welder

- Co2 Welder

- Aluminum Welder

- Other Welding Equipment

- welder

- Plasma Cutter Welder

- high frequency machine

Recommended Products

- MG172 CNC 4-axis gantry welding

- MG138 Electric boxes bottom corner seam welding

- MG107B Two axis corner seam welding

- Contact tip

- Aluminum Oxide Copper Spot Welder Needle Welder Pin Electrodes For Battery Welding Machines

- AITOP Positive Negative Electrode Testing Battery 18650/21700/26650/32650/32700/32140/33140 Battery Pack welding point Tester

- AITOP Single & Double Side Spot Welding 18650,26650,32650 Motorbike battery pack automatic spot welder

- AITOP machine is used for 18650,26650,32650 cylinder Motorbike battery pack automatic spot welding

- Drill stabilizer hardbanding machine

- Movavle hardbanding machine

- Hardbanding welding machine

- Container type hardbanding machine

Find Similar Products By Category

- Industrial Equipment & Components > Welding Equipment > Arc Welder

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

David xiao

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

David xiao

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile