Home > Products > U bend Tube > U Bend ASTM A688 Tube;Feedwater heater tubes

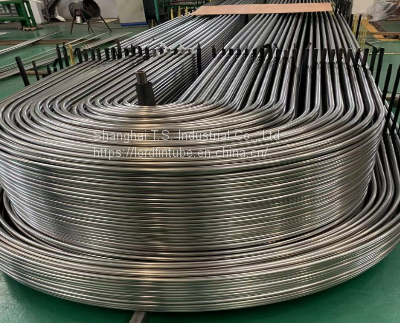

U Bend ASTM A688 Tube;Feedwater heater tubes

- 3000 Piece / Pieces per Month

- shanghai

- T/T L/C

- 70 days

You May Like

-

U-bend Seamless tubes SB-444 UNS N06625SB-163 UNS

-

U-shaped Monel 400 Tube | B163 UNS N04400 Tube

-

Ferritic Steel Tube TP405|U Bend Ferritic Steel Tube ASTM A268

-

U bend Boiler Tube,U Bent Cold Drawn Seamless Tubes

-

Serpentuator, Serpentine tubes, S-Shape Tubes

-

180° elbow; U bend elbow; Short radius elbow; Long radius

Product Details

| Brand Name | Lordfintube | Place of Origin | China | |

| Model Number | F052 | Certification | Other, ISO | |

| Application | Heater Parts | Type | Other, U Bend Tube |

Product Description

ASTM A688/A688M Standard Welded Austenitic Stainless Steel Feedwater Heater Tubes

ASTM A688/A688M Scope

- This specification covers welded austenitic stainless steel feedwater heater tubes including those bent, if specified, into the form of U-tubes for application in tubular feed-water heaters.

- The tubing sizes covered shall be 5 ? 8 to 1 in. [15.9 to 25.4 mm] inclusive outside diameter, and average or minimum wall thicknesses of 0.028 in. [0.7 mm] and heavier.

- The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

ASTM A688/A688M Materials and Manufacture

- The tube shall be made from flat-rolled steel by an automatic welding process with no addition of filler metal.

- After welding and before final heat treatment, the tubes shall be cold worked either in both the weld and base metal or in the weld metal only. The method of cold work may be specified by the purchaser. When cold drawn, the purchaser may specify the minimum amount of reduction in cross-sectional area or wall thickness or both.

- Many surface contaminants may have detrimental effects on high-temperature properties or corrosion resistance of tubing. Contamination by copper, lead, mercury, zinc, chlorides, or sulfur may be detrimental to stainless steel. The manufacturer shall employ techniques that minimize surface contamination by these elements.

ASTM A688/A688M Cleaning Before Annealing

- All lubricants of coatings used in the manufacture of the straight-length tube or the bending shall be removed from all surfaces before any annealing treatments. U-bends on which a lubricant had been applied to the inside surface during bending shall have the cleanness of their inside surface confirmed by blowing close-fitting acetone-soaked felt plugs through 10 % of the tubes of each bend radius. Dry, oil-free, air or inert gas shall be used to blow the plugs through the tubes. If the plugs blown through any tube show more than a light gray discoloration, all tubes that have had a lubricant applied to the inside surface during bending shall be recleaned. After recleaning, 10 % of the tubes of each bend radius whose inside surface had been subjected to bending lubricants shall be retested.

ASTM A688/A688M Surface Condition

- The straight tubes, after final annealing, shall be pickled using a solution of nitric and hydrofluoric acids followed by flushing and rinsing in water. If bright annealing is performed, this requirement does not apply.

- Alight oxide scale on the outside surface of the U-bend area shall be permitted for tubes that have been electric-resistance heat treated after bending.

ASTM A688/A688M Workmanship, Finish, and Appearance

- Tubing purchased to this specification is intended for use in heat exchangers, and will be inserted through close-fitting holes in baffles or support plates, or both, spaced along the tube length. The tube ends will also be inserted into very close-fitting holes in a tube sheet and expanded and may be welded therein. The tubes shall be able to stand expanding and bending without showing cracks and flaws, and shall be finished reasonably straight and suitable for the intended purpose.

- The residual chloride salt contamination of the inside and outside surface of the tubing at the time of packing for shipment from the mill shall not exceed a concentration of 1 mg/ft2 [10.7 mg/m2 ] of the tube surface. One tube in each of five hundred pieces shall be checked immediately before packing for shipment for chloride salt contamination by a procedure agreed upon by the manufacturer and purchaser.

Contact Us

- Shanghai T.S. Industrial Co., Ltd

- Contact nameEstela Chat Now

Product Categories

| Finned Tube | Tube Sheet | U bend Tube | Steel Tube |

| Aluminium Products | Stainless Steel Products | Copper Nickel Products | Titanium Products |

New Products

-

Stainless Finned Tube

-

Brazing Fin Tube

-

Bimetallic Finned Tube

-

Oval Finned Tube

-

High Finned Tubes

-

Seamless Nickel Alloy Tube

-

Super Long Seamless Tubes; Ultra Length Stainless Steel Tube

-

Ferrite Tube, Superferrite Tube, TP405, TP444, TP446

-

Membrane Water Wall Panel | Membrane Wall

-

Cold-Finished Seamless Tubes A210

-

Hydraulic Tube St35

-

DOM Tube T5

Popular Searches

- aluminum tube

- stainless steel

- Carbon Steel Pipe

- Pipe Tube

- Silicone Tube

- industrial pipe

- stainless steel tube

- heat exchanger tube

- carbon steel tube

- led u lamp

- bending tube

- high precision tubing

- super duplex steel

- bright annealed tube

- hydraulic tubing

- cold drawn tubing

- stainless steel coiled tube

- Seamless Stainless Steel Tube

- hydraulic cylinder stainless

- Alloy Steel Tube

- Bike Tube

- duplex steel tube

- bent tube

- welded duplex steel pipe

- pipe fitting

- Steel Pipe

- Stainless Steel Sheet

- Stainless Steel Strip

- Stainless Steel Plate

- steel sheet

Recommended Products

- high and low pressure sensor YCQB01L403 YCQB03L403

- Sanhua MQ-D03024-001001 solenoid valve coil; MQ-A03024-00001

- AIKES full synthesis AKS-816-32#68# environmental refrigerant refrigerant oil 4L 20

- Potassium-Sodium Separation Evaporator

- Danfoss dryer filter DCL DML163 023Z504391 023Z500

- SANRONG oil separator SRW-5205 SRW-6203 SRW-6204 SRW-6205

- HPEOK dry filter PKEK-303S 304S 305S 306S 307S 309S

- sanhua two-way drying filter STG084S STG-B08040-901

- sanhua two-way drying filter STG-B30070-901 DTGB-307S STG-B16050-901 DTGB-165S

- YCVSH20 -77GSHC-1 sanhua Check valve; Shut-off valve

- pressure sensor; transducer YCQB02L12 02H18 05L01 YCQC02L18 03L05 sanhua

- SANHUA Refrigerant Cold Storage Air Conditioner Three Flower Sight Glass SYJ16 SYJ19 SYJ22H01 /8 3/4 7/8

Find Similar Products By Category

- Industrial Equipment & Components > Heater & Heat Exchanger > Heat Exchanger

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Estela

Hi there! Welcome to my shop. Let me know if you have any questions.

Estela

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile