Home > Products > Top sales products > blue nylon/PA/PA66/PA 6 bar

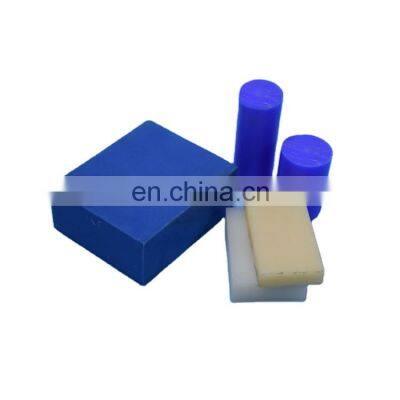

blue nylon/PA/PA66/PA 6 bar

- T/T Credit Card

You May Like

-

Laser cutting acrylic/pmma/perspex shapes machining parts

-

Laminate Sheet FR4/ G10/G11 Epoxy Fiberglass High Voltage Insulation Sheet

-

PVC sheet Polyvinyl Chloride sheet pvc rod pvc plastic welding rod

-

Engineering plastics Amber Color Polysulfone PSU Sheet and Bar PSU Rods

-

High-quality plastic products directly ODM OEM 0.2mm 1mm super clear pvc film

-

High Glossy Engineering Plastic Clear Transparent Flat Rigid PVC Sheets

Product Description

blue nylon/PA/PA66/PA 6 bar

PA is abbraviation of polyamide and nylon .Cast with 100% virgin nylon by molding of casting nylon PA6, PA66 sheet. Nylon PA is recognized as the most widely used and known engineering plastic in the current market. PA6 has the best performance, very tough, even at low temperatures, and high hardness in the surface, toughness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials. Its widely used in a variety of mechanical structures and spare parts. Compared to PA6, PA66 own the higher hardness, rigidity, a good resistance to wear and heat deflection temperature. Apply to Bearings, gears, wheels, roller shaft, water pump impeller, fan blades, oil delivery pipe, oil storage pipe, rope, fishing nets and transformer coi

Specification of nylon/PA :

PA sheet /nylon sheet /polyamide sheet

1.standard size :600*1000mm,600*1200mm,1000*1000mm,1200*1200mm

2.packing:solid pallet with protective film inside pallet

3.thickness:5-100mm

lor:white,black ,blue, other color can be customized

Features of nylon/PA :

1. high strength and stiffness

2. high impact and notch impact strength

3. high heat deflection temperature

4. good at dampening

5. good abrasion resistance

6. low coefficient of friction

7. good chemical stability against organic solvents and fuels

8. excellent electrical properties, ease of printing and dyeing

9. food safe, noise reduction

Application of nylon/PA :

Widely used in chemical machinery, equipment, anti-corrosion system of gears and parts bad materials. Wear-resistant parts, transmission structural parts, household electrical appliances spare parts, automotive parts, screw to prevent the mechanical parts, chemical and mechanical parts, chemical equipment.

related date

| Tensile yield strength | 650-900Kg/cm2 |

| Tensile breaking strength | 490-820Kg/cm2 |

| Vicat heat | 160-180Kgcm/cm2 |

| Heat distortion temperature | 58-65Kgcm/cm2 |

| Water absorption (24h) ≤ | 1.5% |

| Dielectric strength ≥ | 12kV/mm |

| pakaging | solid pallet with protective film inside pallet |

1. uaual protected by pallet and protective film

2. as your requirment.

[About Us]

Q: Can I have details about your company?

A: We are a Manufacturer , one of market leader for Engineering Plastic , Insulation material , also Processing Products and Plastic Displays Stand in china , more than 17 years experiences with 2 own factories , more than 80 worker .

Our wide product range cover mica sheet,epoxy sheet,bakelite sheet,nylon,ABS,PE,PP,PU,PC,PVC,POM,PTFE,PMMA,HDPE etc,and other related plastic products.

Q: Where is your factory?

A: Our factories are located in No.64 Jixiang Road, Longteng Industrial Zone,longgang district ,shenzhen

Q: How many workers in your factory?

A: We have 80 experienced workers with over 5 years experience. Also, we have in house R & D department.

Q: Can I visit you at available time?

A: For sure. You are warmly welcome to visit us at your convenient time. Once you confirm your schedule please let us know.

We would be very glad to assist you to book the hotel and flight. We can pick you up at your hotel to our factory.

[Sample Order Tips ]

Q: How can I get a sample?

A: Before start your sampling, we need to confirm product details with you including specification to avoid any possible misunderstanding.

Q: How long for sampling?

A: It usually needs 2 days. The actual time is up to how many sample orders we receive.

Q: How about the delivery time for sample?

A: For air or express, it only needs several days.

[Mass Order Notes]

Q: What’s MOQ?

A: The MOQ is mainly decided by the specific product,the MOQ is 1 Piece.

Q: What’s the lead time for mass order?

A: For mass order,the lead time is usually 15 -20 days from the date we receive your deposit or original L/C.

Q: What types of price term you can offer?

A: Our price term is mostly FOB Shenzhen. Also, we can do CIF your port but we need to know the nearest port to your place.

Q: What payment term for mass order?

A: For mass order, we can accept TT, irrevocable L/C at sight. For small amount, we also can accept paypal.

[Quality Assurance]

Q: Is there any quality guarantee for your product?

A: Usually, we offer our customers two year quality guarantee for our products. It only suits the condition of proper use on the products.

[R & D]

Q: If I have some idea, can you help me?

A: Yes, we would be very pleased to do it. Once you have some idea please send it to us. We would be able to assist you to finish it. You can contact us via below methods:

Contact Us

- Shenzhen Xiongyihua Plastic Insulation Ltd.

Product Categories

| Engineer Plastic Sheet / Rod / Film / Tube | Insulation Sheet / Rod | Special Engineering Plastics | Top sales products |

| Ungrouped |

New Products

-

Knife Handles Material Colored G10 Laminate Fiberglass Sheet

-

Laser Cutting Shapes Acrylic Round Acrylic Sheet

-

Colorful New Energy Board G10 insulation laminated sheet

-

NATURAL PSU PPSU POLYSULFONE SHEET

-

Good quality Anti-static insulation black and orange color bakelite sheet and can support to producing

-

1000*2000mm Pertinax Red / orange / black color Bakelite Sheet Made in China

-

Thickness 50MM 100MM Insulation Material Orange Bakelite Sheet for Moulding

-

Superior dielectric properties processing bakelite sheet

-

Electrical Insulation Material Bakelite Board/Sheet/Plate in Factory Price

-

Phenolic Laminate Pertinax Bakelite Sheets

-

Electrical Insulation Material Bakelite Board Manufacturer

-

High Temperature Application Phenolic board and Bakelite Insulation Parts

-

Insulation Processing Bakelite Sheet Phenolic Bakelite Plate

-

Electrical Insulation Bakelite Board Bakelite Plate

-

Copper Clad Sheet for PCB Usage /CCL Board

-

Cut-to-size CNC machine insulation bakelite 0.5-100mm board of electrical panel

-

Manufacture of High Quality 3240 Epoxy Phenolic with free sample

-

3025 insulate sheet brown phenolic cotton laminated sheet

-

High Dielectric Strength Fr4 Epoxy Glass Sheet

-

Lenticular Glass Sheet FR4/G10

-

G10 FR4 Electrical part insulation material plastic sheet

-

Fiberglass Fr4 Board Fr-4 Processed Parts . Epoxy Resin Thickness 0.5-30 Mm

-

Excellent FR4 epoxy sheet dielectric material FR4 resin sheet yellow/black FR4 glass fiber epoxy plastic sheet

-

Phenolic Cotton Cloth Rod Bakelite Insulated Panel Rod

Popular Searches

- masterbatch

- Flame Retardant Masterbatch

- Calcium Masterbatch

- plastic masterbatch

- container desiccant bag

- color masterbatch

- Lightweight Eva

- Foam Roll Eva

- black masterbatch

- masterbatch color

- white masterbatch

- caco3 filler masterbatch

- filler masterbatch

- plastic red masterbatch

- masterbatch filler

- Plastic Masterbatches

- Plastic Color Masterbatch

- Black Color Masterbatch

- Plastic Filler Masterbatch

- Blue Masterbatch

- Red Masterbatch

- Pet Raw Material

- Pvc Raw Material

- pom plastic

- Master Batch Pp

- master batch

- Rubber Masterbatches

- Master Batch Compound

- tpu material

- Abs Plastic Sheet

Recommended Products

- Wholesale Eva Va900 extrusion grade hot melt adhesive for yoga mats

- EVA Korea Lotte Chemical VA900 hot melt adhesive strong bonding large packaging film plastic raw materials

- Factory Supply 18J3 Supplier Lg Eva Ea28400 Va28% Plastic Resin Eva Ethylene Vinyl Acetate

- EVA EA28150 granules with excellent sensory properties for hot melt adhesives

- Hot melt grade Lotte Chemical EVA VA900 for adhesive film

- China supply ethylene vinyl acetate copolymer plastic granules EVA Ea28400 resin material

- Wholesale, powder, liquid, granules, granule suppliers, 3D printer filament, eva foam, VA900 plastic raw material resin

- EVA Korea LG EA28150 Ethylene copolymer resin VA content 28% Ethylene-vinyl acetate copolymer resin

- EA28400 EVA ethylene vinyl acetate copolymer plastic resin granules plastic raw material with favorable price

- High quality plastic granules EVA EA28150 granules eva resin ethylene vinyl acetate for hot melt adhesive

- LG EVA Resin EA28400 EVA Pellets Ethylene Vinyl Acetate Copolymer Extrusion Grade EVA Pellets VA28% Melt Flow Rate 400

- Long-term supply of EVA Korea LG EA28150 high fluidity hot melt adhesive grade lipolysis 150 high fluidity

Find Similar Products By Category

- Chemicals > Plastic & Polymer > Polymer & Resin

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile