Home > Products > Potato starch production line > Large output sweet potato starch processing machine for sweet potato starch production

Large output sweet potato starch processing machine for sweet potato starch production

US$ 5000 - 10000

/ Set

1 Set(Min. Order)

- Ningbo,Qingdao,Tianjin

- T/T L/C D/P D/A Credit Card PayPal Other Cash Escrow

You May Like

-

Food grade and large output cassava starch processing machine in cassava starch production line

-

Hot sale and factory price garri production line machine and garri processing machinery

-

Multi-standard and durable cassava flour processing machine and cassava flour making plant

-

Popular and high quality potato starch processing machine and potato starch production line

-

potato starch processing machine

-

Industrial sweet potato starch processing machine

Product Details

| Brand Name | DOING | Place of Origin | China | |

| Model Number | Multi-standard | Use | sweet potato starch processing industry | |

| Certification | Yes | After-sales Service Provided | Engineers available to service machinery overseas | |

| Condition | New |

Product Description

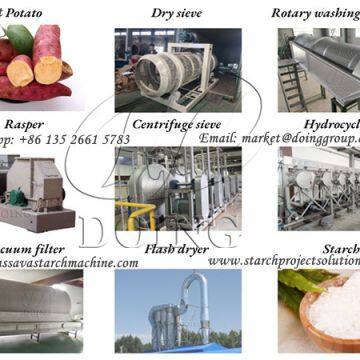

(1) Raw material receiving and washing during the sweet potato starch production line:

The sweet potato is carried besides the storage pool after weighing. Firstly, it goes through the vibration sieve for removing the stones and sand. Then the pre-cleaned potato falls on the belt conveyer and enters into the storage pool, and the rubbish will be carried away by truck.

The sweet potato is carried besides the storage pool after weighing. Firstly, it goes through the vibration sieve for removing the stones and sand. Then the pre-cleaned potato falls on the belt conveyer and enters into the storage pool, and the rubbish will be carried away by truck.

(2) De-stone and washing unit of Potato starch extraction plant:

Sweet Potato is transferred into the screw destone machine to be cleaned by water flow. The small sand and stone go through the rotary screen then meet with bigger size stone which was stopped and sent back to the entrance of de-stone machine. Most of sand and stone are removed out of de-stone machine.

Then the sweet potato is sent by bulk elevator into temporary storage in which it can stay 2 hours.

Sweet Potato is transferred into the screw destone machine to be cleaned by water flow. The small sand and stone go through the rotary screen then meet with bigger size stone which was stopped and sent back to the entrance of de-stone machine. Most of sand and stone are removed out of de-stone machine.

Then the sweet potato is sent by bulk elevator into temporary storage in which it can stay 2 hours.

(3) Crushing unit of sweet potato starch production line:

The Crushing unit is the most important step for sweet potato starch production. The feeding screw combined at bottom of the storage tank pumped the clean potato into milling machine. Highly-efficient milling machine will release the starch in potato at most.

The Crushing unit is the most important step for sweet potato starch production. The feeding screw combined at bottom of the storage tank pumped the clean potato into milling machine. Highly-efficient milling machine will release the starch in potato at most.

(4) Centrifugal extracting unit of sweet potato starch production line:

The mixture is transferred to the 3 stage centrifugal sieves, each sieve works with a fiber pump and a defoam pump. The mixture enters into each sieve to separate residue and starch. After 3 stages continuous washing and separation, the filtrate is sent to concentration and refining unit, and the residue is sent to the residue dewatering unit.

The mixture is transferred to the 3 stage centrifugal sieves, each sieve works with a fiber pump and a defoam pump. The mixture enters into each sieve to separate residue and starch. After 3 stages continuous washing and separation, the filtrate is sent to concentration and refining unit, and the residue is sent to the residue dewatering unit.

(5) Potato residue dewatering unit of sweet potato starch production line:

The potato residue will be pumped to the centrifugal sieve for dewatering, the centrifugal sieve works like the extraction sieve. Then the screw conveyor discharges the residue out of the process, and the water will go back to the process water system.

The potato residue will be pumped to the centrifugal sieve for dewatering, the centrifugal sieve works like the extraction sieve. Then the screw conveyor discharges the residue out of the process, and the water will go back to the process water system.

(6) Concentration and refining unit of sweet potato starch production line

The starch milk from centrifugal sieve goes into the 16 stages of refining hydro-cyclone, and fresh water comes into the cyclone from the end of system. Firstly, starch milk is pumped into 3 stages of concentration unit to remove the water, then the condensed starch milk enter the next 13 stages of washing unit, and the overflow enters into another 2 stages of recycle unit to recycle starch. Most of the effluent with fiber is discharged out of the process, and a little part goes back to the process water system. Finally, the condensed starch slurry is pumped into the starch slurry storage tank.

The starch milk from centrifugal sieve goes into the 16 stages of refining hydro-cyclone, and fresh water comes into the cyclone from the end of system. Firstly, starch milk is pumped into 3 stages of concentration unit to remove the water, then the condensed starch milk enter the next 13 stages of washing unit, and the overflow enters into another 2 stages of recycle unit to recycle starch. Most of the effluent with fiber is discharged out of the process, and a little part goes back to the process water system. Finally, the condensed starch slurry is pumped into the starch slurry storage tank.

(7) Vacuum dewatering unit of sweet potato starch production line:

The starch slurry is pumped into inlet tank of vacuum dewatering machine. Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump. The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

The starch slurry is pumped into inlet tank of vacuum dewatering machine. Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump. The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

(8) Air drying unit of sweet potato starch production line:

After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch.

The package machine will be according to the customers' special requirements.

Whats app: +86 135 2661 5783

Email: market@doinggroup.com

Website:

Website:

Contact Us

- Doing Holdings - Henan Jinrui

- Contact nameZhao Chat Now

- AddressRoom 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District, Zhengzhou, Henan

Product Categories

| Cassava starch production line | Cassava flour production line | Garri production line | Potato starch production line |

| Sweet potato starch production line | cassava processing machine |

New Products

-

Potato starch processing machine

-

High efficient cassava starch processing machine for sale

-

Cassava starch making machine

-

Potato starch processing equipment

-

China cassava starch machine for cassava starch production

-

cassava starch processing line

-

Industrial potato starch manufacturing process and the used potato starch procesing machine

-

China high quality tapioca starch machine for tapioca processing plant

-

High efficient potato starch equipment for potato starch production line

-

Potato starch making process and potato starch processing machine

-

How potato starch is made ?

-

Cassava starch processing machine for cassava starch processing plant

-

Isolation of starch from potato machine for potato starch porcessing

-

Cassava starch extraction machine for cassava statch processing

-

Industrial tapioca starch processing machine for cassava processing

-

Automatic cassava starch machine low price for sale

-

Small scale cassava starch processing plant low price for sale

-

Automatic cassava starch processing line in cassava starch processing plant

-

garri processing machine for making garri

-

Cassava starch processing machine for making starch

-

Cassava flour processing equipment for making high quality cassava flour

-

Garri making machine for processing cassava into garri in garri processing plant

-

New design high efficiency cassava chips cutting machine cassava chips cutter

-

Garr making machine in garri processing line

Popular Searches

- cutting tool

- hand tool

- plastic extruder

- injection mould

- machinery part

- production line

- milling machine

- sand casting

- filling machine

- cutting machine

- packaging machine

- welding machine

- construction equipment

- sealing machine

- packing machine

- making machine

- cleaning machine

- roll forming machine

- laser engraver

- cnc router

- fiber laser marking machine

- machine tool

- cnc lathe

- cnc machine

- fiber laser cutting machine

- pet food

- fresh vegetable

- starch production line

- cassava

- gummy

Recommended Products

- Floating Fish Feed Extruder Machine for Aquaculture and Pet Food Production

- 250–400 kg/h Diesel Pellet Machine for Animal Feed

- 150-200kg/h Fish Feed Extruder

- Soybean cleaning screen, corn and wheat impurity removal vibrating screen, grain selection screen

- Grain cleaning screen, corn and wheat impurity removal and selection machine

- Small chain threshing machine, grain threshing and loading machine

- Grain grain gravel gravel machine chain scraper warehouse

- Grain unloading machine, bulk grain loading machine, and grain scraping machine

- Environmentally friendly grain selection sieve, corn, wheat, soybean impurity removal sieve

- Grain impurity screening machine, corn and wheat cleaning machine

- Grain cleaning screen, rice impurity removal drum screen, soybean cylindrical cleaning screen

- 130–180kg/h Poultry Feed Pellet Machine – 4.5KW Animal Feed Equipment for Small Farms | Kawise

Find Similar Products By Category

- Manufacturing & Processing Machinery > Agricultural Machinery > Feed Processing Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Doing Holdings - Henan Jinrui

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Zhao

Hi there! Welcome to my shop. Let me know if you have any questions.

Zhao

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile