Home > Products > New Products > competitve price with superior quality wood briquette extruder machine

competitve price with superior quality wood briquette extruder machine

- qingdao/shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

-

easy to install and to maintain wood briquette extruder machine

-

Factory direct sell and high quality wood briquette extruder machine

-

low energy consumption Honeycomb briquette pressing Machine

-

New design sawdust wood pellets machine / wood pellet mill for sale

-

New design sawdust wood pellets machine for sale

-

High qulity Automatic granule packing machine CE approved

Product Details

| Condition | New | Place of Origin | Henan, China | |

| Brand Name | Hennan Meshen | Model Number | MF | |

| Voltage | 220V/380V/420V | Power(W) | 15-22KW | |

| Weight | According to different types | Dimension(L*W*H) | According to different types | |

| Certification | CE ISO | Warranty | 12 months | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

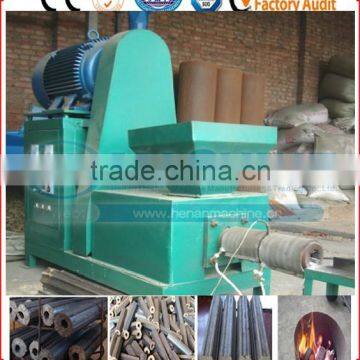

competitve price with superior quality wood briquette extruder machine

Introduction of Wood briquettes extruder machine:

This Wood briquettes extruder also called biomass briquette machine and sawdust briquette making machine, is used to make sawdust into half-charcoal-stick. It is equipped with the auto

controlling heating system. The byproduct of this machine can be used to heat boiler, fireplace, etc for warm in house. Using the inherent characteristics of wood raw materials, through the screw extrusion, high temperature, high pressure, the wood raw material to make micro-fiber lignin plastics combine to form a fuel rod. It is the main equipment to make stick solid fuel with such wood material as bits of wood, rice shell or peanuts shell, etc. The raw material(12% Water proportion) dried by the dryer(12% humidity)will be formed into fuel under high pressure and at high temperature. During this process, no need to use binder and noxious chemical.

Working Principle of Wood briquettes extruder machine

1. Crush the raw material into small pieces (diameter is about 3-5mm)

2. Dry the material by machine or dried it in the sun , till the moisture is less than 12%

3. Put the material into briquette press machine without add any chemical goods, it should accord to the high temperature

4. Produce the briquette stick from biomass material without any additive

5. Carbonized the briquette stick

6,Finished briquette have 50MM,70MM diameter can be choice

Detailed parameters of all the models for your checking:

Model | MF-50 | MF-80 |

Output (kg/h) |

180-210 |

340-360kg |

Motor Power (kw) |

15 kw |

22kw |

Electric heater (kw) |

2kw×3pcs |

2kw×3pcs |

Weight(kg) |

700 kg |

1100kg |

Overall dimension(mm) | 1780*750*1290 | 1960*880*1620 |

Size of finished products |

Diameter: |

Diameter: |

Spare parts of Briquette Making Machine:

- Long Life of Screw Shaft

Our machine adopts a durable material (high hardness alloy steel) to make the shaft. We use a different process then what is normally used to make the screw shaft. The screw shaft is manufactured with a milling machine which guarantees that the distance between every screw is the same, and the angle of every screw is the same.

- Long Life of Inner Former

The Inner Former can be used for 1-2 years.The former is made from a whole steel bar through a water jet cutting system so that the inner face is smooth. Therefore, it’ll be easier to form and save energy. This is why the finished produces such as sawdust briquettes are smooth. It consists of two parts and you need to change only the key part when it is worn.

- Heating section - we adopted two heat collars which are made from thick copper wires and are ceramic inside

Lubricating System

.

The gear box is equipped with lubricating system. Moreover, to oil the gear box properly, our briquette machine is designed with an exhaust function which can help maintain consistent air pressure.Auto Cutting System

It’s a simple piece of equipment composed of two steel plates. (Please see the picture), and briquettes can be automatically cut in uniformed lengths.

Payment,Packing and Delivery

Payment :30% TT in advance, 70%6TT balance pay off before delivery.

Packing: The machine and wear parts will protected by plywooden box or as customers’ will.

Delivery time: For one set, the delivery time is 7-10 days, for 1-5 sets 20-25 days, above 5 sets usually negotiate.

Shipping company: MSK/MSC/APL/EMC/WANHAL/KLINE and We will remind you before boat arrive and offer you all the customs clearance documents on time.

Contact Information

Thanks for your interest in our machines and please contact us freely if you have any questions ot requirements by the following contact information. Your visit of our factory to test the machines you like will be warmly welcomed. Hope to have have the honor to cooperate with you in the bright future.

Contact Us

- Henan Meshen Machine Manufacturing & Trading Co., Ltd.

- Contact nameLanlan Ren Chat Now

- Phone0086-0371-64575888

- AddressNongye Road,Jinshui District, Zhenzghou,Henan, China, Zhengzhou, Henan

Product Categories

New Products

-

Automatic sawdust bagging machine approved by CE

-

Economic favourable price See larger image Sugarcane sawdust charcoal rods briket machine to make wood briquette

-

Automatic and Economic peanut shell briquette press machine with best price

-

Waste wood sawdust briquette form machine/briquette machine from sawdust in China

-

China Manufacture coal dust small straw rice husk wood biomass sawdust briquette machine

-

New type of boiler fuel,sawdust log briquette machine/straw log briquette machine/wood log sawdust machine

-

No chemical binder perfect quality biomass sawdust wood briquette charcoal making machine

-

Discount Price!!! 2015 Professional Factory made Best sawdust briquette charcoal making machine/wood charcoal making machine

-

2015 new design charcoal briquette sawdust briquette wood briquette machine

-

Low ash reproducible sources wood charcoal extruder machine, sawdust briquette machine for barbecue

-

High Benefit wood charcoal rod extruder making machine

-

Advanced Straw briquette Extruder Machine with Easy Operation

-

China professional briquette machine wood sawdust/extruder wood briquette machine

-

China made biomass briquette making machine plant/wood timber briquette press equipment

-

2015 NEW Biomass wood bamboo charcoal briquette extruder machine

-

Large output and low consumption charcoal stick extruder machine

-

Environmental protection Wood sawdust briquettes extruder machine

-

CE and ISO certificated biomass straw coal briquette machine with factory price

-

Hig quality biomass straw coal briquette machine with factory price

-

CE and ISO certificated biomass coal briquette machine with factory price

-

CE and ISO certificated Bio coal machine with factory price

-

Bio coal briquetting machine with clients' highly speaking

-

Bio coal briquette machine with clients' highly speaking

-

Argro waste charcoal plant(with clients' highly speaking)

Popular Searches

- coconut shell

- Pellet Making Machine

- straw machine

- Product Coconut Fiber

- charcoal coffee

- power saver

- Wood Processing Machine

- briquette plant

- Wood Pellet Mill

- Palm Fiber

- Pellet Mill

- Pellet Machine

- briquette making plant

- alfalfa

- Straw Pellet Making Machine

- Wood Pellet Making Machine

- artificial grass machine

- pellet press

- power factor saver

- sawdust briquette

- briquette extruder

- Briquette Production Line

- charcoal powder shaping machine

- charcoal rod extruder

- cocoa shell

- sawdust drying system

- energy saving machine

- Wood Hammer Mill

- Sawdust Hammer Mill

- Wood Chip Hammer Mill

Recommended Products

- Biomass to Biochar Pyrolysis Machine - Automatic Charcoal Making Machine for Wood/Coconut Shell/Agriculture Waste

- Biochar Pyrolysis Machine | Carbonization Furnace for Wood/Coconut Shell/Rice Husk

- Biochar pyrolysis plant | High yield carbonization furnace for charcoal

- Kawise Biomass Pellet Machine – High-Efficiency Pelletizing Solution

- Charcoal Production Machinery for Coconut Shell/Wood/Biomass Briquette Production

- Flat Die Biomass Pellet Mill – Turn Waste into Clean Energy

- Charcoal Briquette Press Machine Converts Sawdust/Coconut Shell/Rice Husk/Wood Into Charcoal

- Maximize Efficiency with the Kawise Small Pellet Machine

- The Growing Demand for Biomass Pellets and the Role of Biomass Pellet Machines

- Maximize Efficiency with a PTO-Driven Pellet Mill for Feed & Biomass Production

- Enhance Your Production Efficiency with Our Diesel Pellet Mill

- Choosing the Right Raw Materials for Biomass Pellet Production

Find Similar Products By Category

- Manufacturing & Processing Machinery > Woodworking Machinery > Wood Pellet Mill

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lanlan Ren

Hi there! Welcome to my shop. Let me know if you have any questions.

Lanlan Ren

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile