Home > Products > MEIBAO Hot Air Furnace > Direct Coal-fired Hot Air Furnace

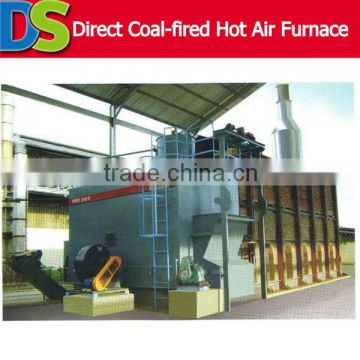

Direct Coal-fired Hot Air Furnace

- 100 Set / Sets per Month

- Shanghai/Ningbo ports etc

- T/T PayPal

You May Like

Product Details

| Condition | New | Type | Hot Air Furnace | |

| Brand Name | DS | Model Number | DS-MBZ | |

| Voltage | 380V | Power(W) | 2.8/52.4 | |

| Dimension(L*W*H) | customized | Weight | customized | |

| Certification | ISO9001 | Warranty | One year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

Hot Air Furnace1.Professional manufacturer;

2.First-class product and service;

3.Facilitator of fortune 500 companies.

Direct Coal-fired Hot Air Furnace

Operating Preinciple

MBZ direct coal-fired hot air furnace consists of MBL coal fired machine, high temperature urifying room and air mixing room.

Bituminous coal (soft coal) is fed into coal hopper through coal feeder. The coal at a certain height is delivered into buring hearth of coal burner by chanin grate. Combustion fan sends air into burner, hot gas produced by burning coal erupts from fire outlet of coal burner and enters in high temperature purifying room.The cinder is discharged from the other side of coal burner by cinder conveyor.

Hot gas enters in high temperature purifying room and begins secondary combustion. The dust in the gas impact, aggregate and subside in the prifying room. Clean hot air from purifying room at about 1000 deg. C then mixes into a certain amount of fresh air, the mixture at the wanted temperature flows in to dryer(such as spray tower, rotary dryer, oven, drying house, flash dryer, fluidized bed etc.)to dry material. Temperature of hot air can be adjustable according to the demand. When hot air is supplied continuously, its temperature fluctuates within±5 deg.C.

Specifications of Hot Air Furnace

Model | Rated output (X10000 Kar/hr) | Rated coal consumption(kg/hr) | Sistalled power(kw) | Area occuied |

MBZ-25 | 25 | 50 | 2.8 | Based on the actual conditions |

MBZ -50 | 50 | 100 | 3.5 | |

MBZ -75 | 75 | 150 | 3.5 | |

MBZ -100 | 100 | 200 | 4.3 | |

MBZ -125 | 125 | 250 | 4.3 | |

MBZ -150 | 150 | 300 | 6.8 | |

MBZ -200 | 200 | 400 | 7.9 | |

MBZ -250 | 250 | 500 | 8.5 | |

MBZ -300 | 300 | 600 | 8.8 | |

MBZ -350 | 350 | 700 | 8.8 | |

MBZ -400 | 400 | 800 | 10.8 | |

MBZ -450 | 450 | 900 | 10.8 | |

MBZ -500 | 500 | 1000 | 10.8 | |

MBZ -550 | 550 | 1100 | 15.5 | |

MBZ -600 | 600 | 1200 | 15.5 | |

MBZ -700 | 700 | 1400 | 19.5 | |

MBZ -800 | 800 | 1600 | 26.5 | |

MBZ -900 | 900 | 1800 | 26.5 | |

MBZ -1000 | 1000 | 2000 | 36.6 | |

MBZ -1200 | 1200 | 2400 | 43.6 | |

MBZ -1300 | 1300 | 2600 | 43.6 | |

MBZ -1400 | 1400 | 2800 | 43.6 | |

MBZ -1500 | 1500 | 3000 | 43.6 | |

MBZ -1600 | 1600 | 3200 | 43.6 | |

MBZ -1800 | 1800 | 3600 | 52.4 | |

MBZ -2000 | 2000 | 4000 | 52.4 |

Advantages of Hot Air Furnace

1.Heat efficiency>95%;

2.Operate simply, adjust easily;

3.High security, there is no danger of explosion;

4.Durable, low operating cost, easy maintenance;

5.Hot air is very clean, dust content:25-1320mg/Nm3;

6.Sufficient combustion, there is no balck smoke, good operation conditions;

7.All the hot air flows into dryer, there is no increased outlet during production process;

8.Hot air temperature below 900 deg.C can be adjustable easily. When hot air is supplied cntinuously, its temperature fluctuates within±5 deg.C.

Applications of Hot Air Furnace

1.Feedstuff: less, granular feedstuff, DCP, feedstuff additives and so on;

2.Ceramics:ceramic powder(polished tile),glaze,pottery,kaolin and so on;

3.Daily-use Chemical:power detergent, PAA, layer sodium metasilicate, 4A zeolite etc.

4.Other Material:rubber,silica gel,acetylene cylinder,paper mold,ore powder briquette wook and so on;

5.Building materials:quartz sand(for glass), phosphogypsum, sludge desiccation, effluent disposal, solid residue etc.

6.Fertilizers:compound fertilizer,DAP, MAP,potassium choride, potassium sulfate,potassoum magnesium sulfate etc;

7.Chemicls:potassium fluoride,dye(activated, deoxidize), PAC, CaCl2, Fe2(SO3),zinc oxide,alumina,fluorite powder etc;

8.For environmental protection:back liquor(lignin),posphogypsum,sludge desiccatin,effluent disposal,solid residue etc.

Just feel free to write to us to share your ideas!

Contact Us

- Hangzhou Delshine Industry & Trading Co.,ltd

- Contact nameJoe Chan Chat Now

- Phone0086-571-86090322

- AddressRoom1301, New Youth Plaza Building B,Shangtang Rd.,Hangzhou, China, Hangzhou, Zhejiang

Product Categories

New Products

-

Direct Coal-fired Hot Air Coal Fired Furnace

-

Indirect Coal-fired Hot Air Kiln For Ceramic Industry

-

Indirect Coal-fired Hot Air Coal Furnace

-

Direct Coal-fired Hot Air Coal Fuel Heating Furnace

-

Direct Coal-fired Hot Air Blast Furnace Hot Air Stove

-

Indirect Coal-fired Hot Air Coal Combustion Hot Air Furnace

-

Direct Coal-fired Hot Air Coal Fired Hot Air Furnace

-

Indirect Coal-fired Hot Air Hot Air Drying Equipment

-

Direct Coal-fired Hot Air Hot Air Wood Furnace

-

Biomass Fired Biomass Charcoal Carbonization Furnace

-

Biomass Fired Biomass Gasification Furnace

-

Biomass Fired Biomass Hot Air Furnace

Popular Searches

- Tube Bundle Dryer

- Fluid Bed Dryer

- Dryer Equipment

- Spray Drying Equipment

- vacuum dryer

- Plate Drying Machine

- industrial dryer

- Rotary Drum Dryer

- Cross Joint Shaft

- rotary dryer

- drum dryer

- Vacuum Drying Equipment

- Rotary Drying Equipment

- Dryer Oven

- Spray Dryer

- Rotary Dryer Machine

- Industrial Rotary Dryer

- Rotary Drying Machine

- hopper dryer

- Hopper Drying Machine

- Freeze Dryer

- Industrial Centrifugal Dryer

- cowpea seed

- blood gas machine

- Drier Machine

- lab spray dryer

- Drier Equipment

- air tunnel

- air drying

- mineral dryer

Recommended Products

- Yosion Technology YH-9423A Drying Oven;Industrial Oven;Trolley Oven

- Peptide white powder spray dryer Stainless steel plant protein spray drying equipment

- Yosion Technology YH-D2000T Drying Oven;Industrial Oven;Trolley Oven

- Yosion Technology YH-9623A Drying Oven;Industrial Oven;Sample Preparation Equipment

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- .[Energy Efficiency Certified] [24KW Motor/90KG Fuel] Vacuum Dryer for Wood Chips/Straw Drying [Jinan Hengyuruntai Supplier]

- Freeze Dryer

- Vacuum freeze dryer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Chemical Drying Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Joe Chan

Hi there! Welcome to my shop. Let me know if you have any questions.

Joe Chan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile