Home > Products > Sand Blast Machine > Q69 Steel plate continuous shot blasting cleaning equipment

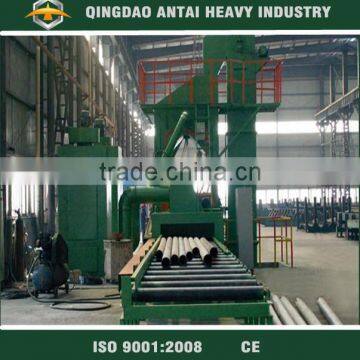

Q69 Steel plate continuous shot blasting cleaning equipment

- 200 Set / Sets per Month

- Qingdao

- T/T

You May Like

-

Q32 series steel plate shot blasting equipmet with tumble blet

-

Q32 Steel plate cleaning sand blast machine tumble belt type

-

Q69 Steel plate cleaning equipment automatic abrasive blasting machine

-

Shot blasting booth/shot blasting room

-

Q326C Overseas service steel shot with good quality

-

Q48 catenary abrator/shot blasting machine

Product Details

| Condition | New | Place of Origin | Shandong, China | |

| Brand Name | Antai or OEM is accept | Model Number | Q6920 | |

| Feature | Critical Cleaning / Residue Free, Non-Ionic, Non-Toxic, Rust / Corrosion Inhibitor, Sudsing / Foaming | Fuel | Electric | |

| Certification | CE, Other, CE, ISO | Use | Descaling / Stripping | |

| Cleaning Process | Other, Steel shot | Cleaning Type | Other, Shot blasting | |

| Industry Used | Other, Construction and bridge professions | Material | Metal / Coil | |

| Power(W) | 156.6 | Dimension(L*W*H) | 30650*6850*9095 | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

WHAT KIND OF INDUSTRY WILL THIS MACHINE BE USED FOR?

Q69 series steel plate and section steel pretreatment line is mainly composed of such stage as preheating, shot blast cleaning, painting and stove, etc.

It is suitable for the surface derusting and painting craft for steel plates and sections in such industries as shipmaking, automobile making, locomtive vehicle, bridge, and machinery.

This steel structure / shot blasting machines belong to the roller type shot blast-cleaning machine ,and mainly used to de-stress and surface de-rust the steel structures, such as Large-scale H steel, etc. In the construction and bridge professions.

*WHAT’S CHARACTERISTICS OF THIS MACHINE?

Features

• Compact design, simple operating principle

• Excellent blast performance

• Great service life

• Tough, hard wearing, manganese clast cabinet

*what's part the machine consists of?

IT'S CONSISIT OF ROLL CONVEYOR,BUCKET ELEVATOR,IMPACT SEPARATOR,ABRASIVE SYSTEM,DUST COLLECTOR SYSTEM,ELECTRICE SYSTEM AND SO ON.

*this kind of machine’s technical parameters as followed.

o. | Model Item | Q698 | Q6912 | Q6915 | Q6920 | Q6925 | |

1 | Width of workpiece | mm | 800 | 1200 | 1500 | 2000 | 2500 |

2 | Size of inlet opening | mm | 800*1600 | 1200*400 | 1500*400 | 2000*400 | 2500*800 |

3 | Length of workpiece | mm | 1200-12000 | 1200-6000 | 1200-12000 | 1200-12000 | 3000-12000 |

4 | Roller speed | m/min | 0.5-4 | 0.5-4 | 0.5-5 | 0.5-4 | 0.5-4.5 |

5 | Thickness of plate | mm | 3-60 | 3-60 | 1.5-60 | 3-60 | 3-60 |

6 | Abrasive flow rate | kg/min | 8*120 | 4*250 | 4*250 | 6*250 | 6*250 |

7 | Abrasive initial fill | kg | 4000 | 4000 | 4000 | 4500 | 4500 |

8 | Adjusting height of rolling brush | mm | 400 | 200 | 350 | 450 | 600 |

9 | Ventilation capacity | m3/h | 22000 | 17560 | 19000 | 19550 | 27758 |

10 | Total power (no dust collector) | kw | 90 | 78.3 | 113.6 | This will help us to design t | |

- What kind of workpiece will you clean? (name, material, processing craft)

- The size of workpieces(max. & min. L*W*H)

- Weight of pieces (max. & min.)

- Main purpose (for sand remove or descaling or other?)

- Requirement for efficiency?

- Any steel plate shot blasting machine can be designed according to your requirement.

Product showing

Cleaning Efficiency

Other type

Packageing&Shipping

Our Service

1.Our technical engineers design the equipment by every customer’s requirement,and will ensure drawing with them,do our best cost saving for them.

2.During the producing, we will take photos in every progress,and send customer’s for tracing.

3.After delivery,we will sending the original documents,such as original B/L,Packing list,Commercial Invoice,Form E,and so on.

4.we supply our customer the English vision base drawing,installing drawing,operating documents and spare parts drawing ,etc.

5.For the spare parts,we company has after sale service system,will send one ID for every customer,Using the ID loading will show the equipment’s information and spare parts,we supply the 24 hours service.

Company Information

Introduction

* 30 years experience for making shot blasting machine.

*A group company,having real estate, machinery and leather bags industry.

*15 experienced engineers to consider every possibility for customers.

*8 of them has over 25 years knowledge of shot blasting technology.

*3D software for auxiliary design. Show every design details in front of you.

*Experienced technicians for production, installation, commissioning & service.

*ISO 9001:2008 certified company, CE certificate will be issued soon.

*All machining parts out sourced from professional CNC machining company with strict quality control procedure.

*Own foundry to produce special material spare parts for our machines. ur best team

our design group assure every step using 3D technology

Our main products

parts exported machines

customer visiting

Certificates

FAQ

1.How many days do you need to produce this machine?

--This is our standard machine and we have some in stock,can be delivered right now after your deposit.

2.What does your factory do regarding quality control?

--We pay much more importance to quality from the very beginning to the end of production,Every machine will be fully assembled and carefully tested before shipment.

3.What’s your machine quality guarantee?

--Quality guarantee time is one year,We choose world famous brand components to keep our machine in perfect working condition.

4.Are you able to give installation and commissioning overseas?How long will it takes?

--Yes,we supply overseas service ,but customers needs to pay for the engineers fight tickets and hotel,food .Small machine usually takes about 20days.

5.How can I trust you to delivery the right machine as I ordered?

--We will absolutely deliver a good quality machine as we discussed and confirmed in the order.The core of our company culture is innovation,quality,integrity and efficiency.Antai is Alibaba’s Gold supplier with BV&TUV assessment.You can check with ALIBABA,We have never got any compliant form our customers.

ANY QUESTIONS PLS ASK MRE FREELY.

Contact Us

- Qingdao Antai Heavy Industry Machinery Co., Ltd.

- Contact nameyan Ji Chat Now

- Phone86-0532-88138566

- AddressShanghaidongyi Street No297,Jiaonan City,Qingdao City, Qingdao, Shandong

Product Categories

New Products

-

Pneumatic shot blasting machine Q48

-

Pneumatic Q48 sand blasting machine

-

Gas cylinder shot blasting machine Q48 hanger cleaning machine

-

China supplier best price Q48 shot blasting machine

-

China supplier best price Q48 sand blasting machine

-

China supplier best price Q48 steel shot/sand blaster for sale

-

Q26Series air blasting room

-

shot blasting room of Q26 series

-

Q26 Series sand blasting room

-

Q26 Series sand blasting gun/sand blasting room

-

CE & After-sales serviced Q26 series cleaning equipment blasting room

-

CE & After-sales serviced Q26 series sand blasting room

Popular Searches

- ultrasonic cleaner

- ultrasonic blind cleaner

- ultrasonic cleaning tank

- radiator cleaning machine

- Ultrasonic Cleaning Equipment

- Degreasing Equipment

- Ultrasonic Washing Equipment

- Dish Washer

- commercial dishwasher

- industrial dishwasher

- Counter Top Dishwasher

- Automatic Dishwasher

- Sink Dishwasher

- Kitchen Equipment Dishwasher

- Stainless Steel Dishwasher

- Mini Dishwasher

- Freestanding Dishwasher

- Portable Dishwasher

- Restaurant Dishwasher

- Dish Washing Machine Dishwasher

- Ultrasonic Cleaners

- ultrasonic cleaning machine

- jewelry cleaner

- ultrasonic bath

- ultrasonic cleaning

- Industrial Ultrasonic Cleaner

- Digital Ultrasonic Cleaner

- Machine Ultrasonic Cleaner

- Dental Ultrasonic Cleaner

- Ultrasound Cleaner

Recommended Products

- Machine for Waste Crude Oil Purifying Machine Used Engine Oil Refining Distillation Plant

- Waste Engine Oil Distillation to Diesel Machine With CE Waste Oil Recycling to Fuel Oil Plant

- Pyrolysis/Waste Engine Oil to Diesel Used Motor Oil Distillation Plant Oil Refining Equipment

- Industrial towel dryer

- Brisbane Automatic Tubes Cleaning System ATCS for shell tube heat exchanger

- New Delhi Automatic Tubes Brushing for Heat exchanger Condenser

- Nanjing Automatic Tubes Cleaning System ATCS for Chiller condenser

- Hangzhou Automatic Tubes Cleaning System ATCS for Chiller condenser

- Riyadh Automatic Tubes Cleaning System ATCS for shell tube heat exchanger

- Abu Dhabi Automatic Tubes Cleaning System ATCS for Chiller condenser

- Kuala Lumpur Automatic Tubes Cleaning System ATCS for shell tube heat exchanger

- Sao Paulo Automatic Tubes Cleaning System ATCS for Chiller condenser

Find Similar Products By Category

- Industrial Equipment & Components > Cleaning Machine > Industrial Ultrasonic Cleaner

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

yan Ji

Hi there! Welcome to my shop. Let me know if you have any questions.

yan Ji

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile