What are Peco filter elements?

Peco filter elements are custom-made filters meant for the removal of contaminants, including solid particles and liquid aerosols, from gases and liquids. They are broadly utilized in industrial fields like oil and gas, chemical production, and power generation to maintain operational cleanliness. These filter elements are recognized for their long life, high efficiency in filtration, and multifunctionality, hence, they are a great choice for protecting equipment and guaranteeing system integrity.

Types of Filter Elements Used in the Industry

Mesh Filter Elements

Mesh filter elements include filters made of woven or perforated materials that capture impurities within their fine screens as they pass through the filter. They are usually used in industrial applications such as rust or debris removal from pipelines, where coarse filtration is required. These filters have numerous options in terms of mesh size, which allows for different operational requirements while ensuring high strength and durability even in difficult conditions.

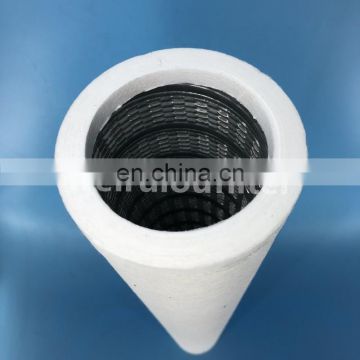

Coalescing Filter Elements

To remove liquid aerosols and fine particulates from gases, coalescing filters are crucial for oil refining, natural gas processing, and other associated industries. These filters work by isolating small droplets and combining them into larger droplets, which can be separated from the air stream. With the efficiency of oil mist and moisture content reduction, coalescing filters make sure that appliances work properly through precise filtration.

Activated Carbon Filter Elements

Filters that seek to neutralize odor and remove harmful vapors or organic compounds utilises activated carbon for its property of absorption. Widely used in vapour and water treatment filters, activated carbon elements have proven to be powerful contaminant absorbers. Activated carbon’s very high surface area also allows for maximum walmart filtration performance making it essential for various environmental application.

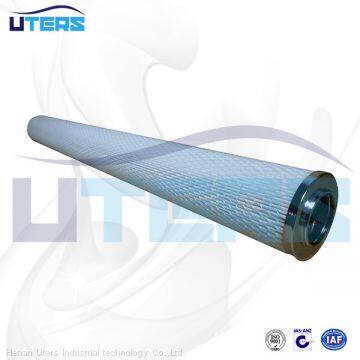

Pleated Filter Elements

Pleated filters are designed to capture dust, dirt and even finer particles while preserving compactness. This filter type is widely used in the pharmaceutical and food processing industries, HVAC systems, and more. Their lifelong value stems from the fact that they provide effortless airflow which minimizes clogging. These filters are an optimum fit for various industries due to their versatility.

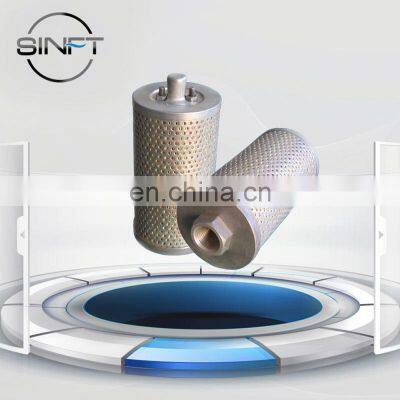

Ceramic and Sintered Metal Filter Elements

These filters were created for maximum durability. Due to their capability to endure corrosive environments and high temperatures, they are perfect for power generation and chemical processing. Their sturdy structure allows for fine liquid and gas filtration while sustaining long-term performance under pressure and harsh conditions.

Every filter type distinguishes itself with specific industrial applications, focusing on efficiency, reliability, and flexibility for operational safety and cleanliness.

How do Peco filter elements work?

Peco filter elements work by precision filtration that separates particulates and contaminants from a gas or liquid using sophisticated materials and designs. These filters contain multiple graded-density media layers which capture a multitude of particles while maintaining a high flow rate. The advanced construction also reduces pressure drop and therefore, energy consumption during operations.

For example, in natural gas processing, Peco filter elements can achieve 99.98% removal efficiencies for 0.3-micron-sized particles. This minimizes particulate-related equipment damage and improves system dependability. Their robust structure and chemical-resistant properties make them highly reliable for use in constantly changing industrial environments, including high temperature or corrosive conditions, maintaining dependability throughout industrial shifts. This ability ensures critical industrial processes can sustain flow without interruption, preserving equipment and compliance over long-term use.

How often should Peco filter elements be replaced?

Peco filter elements usually need to be changed when system performance noticeably drops or as per the manufacturer’s guidelines. Regular checks are needed to assess the remaining life of the filter, however, a rule of thumb is to change the filters between 6 to 12 months based on operating conditions and contaminant levels. For exact filter change intervals suited to your application, always check the user manual or get in touch with an expert.

Signs that a Replacement is Needed

Knowing when a filter change is needed is important for system maintenance, keeping the system in tip-top shape. Common indicators include a reduction in airflow, which might suggest an overloaded filter, and increased system noise as the system is strained during operation. Increased energy use, in less overt circumstances, might suggest that the system is less efficient due to the lower functioning filter. Dirty filters are also an obvious mark that replacement is needed. In heavily polluted environments, especially with heavy daily use, these signs emerge quickly, making them quite frequent, highlighting the need for constant vigilance and swift actions.

Best practices for the maintenance of filter elements

Filter elements can be optimized for performance and longevity if their maintenance is kept up. To fulfill this, I follow a couple of steps. For one, I do periodic checks. Checkups are done only at the set intervals made by the manufacturer, and with operational indicators such as lower efficiency. Careful cleaning of reusable filters is equally important, as using inappropriate cleaning methods, such as strong chemicals, will ruin their structural integrity. Cleaning the area where the filters are kept helps reduce the likelihood of exposure to excess dirt and debris. Where possible, I utilize recommended and requirements-compliant replacement filters. This exempts the system from performance-compromising products due to poor quality. With utmost vigilance and proactiveness, I ensure that no costly repairs will have to be undertaken.

Frequently Asked Questions (FAQs)

What are Peco Filter Elements, and why are they important?

Peco Filter Elements are particularly important as they are used in the filtration of gas and liquids in industrial processes to remove any form of impurities. The unique design of these filter elements improves operational efficiency and effectiveness as filtration systems can capture and remove unwanted particles. This protects the equipment located downstream and increases process safety.

How do Peco Filter Elements enhance filtration efficiency?

Peco filter elements improve filtration efficiency owing to their design and construction and media used which is of very high quality. The constituent parts of the filter are manufactured to provide the appropriate pore structure which ensures adequate retention of particulates and other harmful substances. This design leads to reduced pressure drop and increased filtration, thereby improving operational efficiency.

What types of Peco Filter Elements are available?

Some of the most common types of Peco Filter Elements are depth filters, coalescers, and separator elements. Each type is tailored to specific operations like oil and gas purification, gas filtration, and liquid filtration. These products are customized to fit the demands of multiple industries while striving to achieve maximum efficiency.

coalescer filter element PECO CC28US$ 55 - 75MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

coalescer filter element PECO CC28US$ 55 - 75MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS PECO coalescer & separator filter elements CAA33-5US$ 1 - 30MOQ: 5 PiecesXinxiang Lifeierte Filter Corp., Ltd

PECO coalescer & separator filter elements CAA33-5US$ 1 - 30MOQ: 5 PiecesXinxiang Lifeierte Filter Corp., Ltd PECO facet CAA22-5 coalescer filter elementUS$ 40 - 80MOQ: 1 PieceXinxiang Lifeierte Filter Corp Ltd

PECO facet CAA22-5 coalescer filter elementUS$ 40 - 80MOQ: 1 PieceXinxiang Lifeierte Filter Corp Ltd CB-43-SB peco facet coalescer cartridge filter element CB43-SBUS$ 50 - 70MOQ: 10 PiecesXinxiang Lifeierte Filter Corp.,Ltd

CB-43-SB peco facet coalescer cartridge filter element CB43-SBUS$ 50 - 70MOQ: 10 PiecesXinxiang Lifeierte Filter Corp.,Ltd PECO coalescer filter element PCHG-372 peco PS-240-S2C-20EBUS$ 5 - 100MOQ: 10 Piecestianjin yiming filter co.,ltd

PECO coalescer filter element PCHG-372 peco PS-240-S2C-20EBUS$ 5 - 100MOQ: 10 Piecestianjin yiming filter co.,ltd PECO Natural Gas Fiberglass Filter Separator Elements PCHG-312US$ 60 - 120MOQ: 10 PiecesXinxiang Lefilter Corp.Ltd

PECO Natural Gas Fiberglass Filter Separator Elements PCHG-312US$ 60 - 120MOQ: 10 PiecesXinxiang Lefilter Corp.Ltd PCHG-336 Bowey replaces PECO coalescing filter elementUS$ 20 - 100MOQ: 1 PieceHenan Bowey Machinery Equipment Co., Ltd

PCHG-336 Bowey replaces PECO coalescing filter elementUS$ 20 - 100MOQ: 1 PieceHenan Bowey Machinery Equipment Co., Ltd coalescer filter element PECO CC28US$ 55 - 75MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.

coalescer filter element PECO CC28US$ 55 - 75MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd. coalescer filter element PECO CC28US$ 52 - 72MOQ: 10 PiecesKainuosen Environmental Technology (langfang) Co., Ltd.

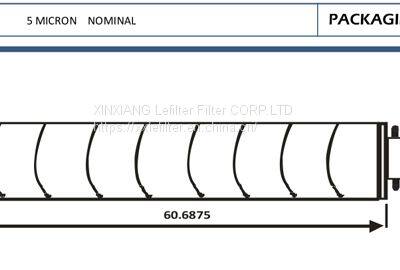

coalescer filter element PECO CC28US$ 52 - 72MOQ: 10 PiecesKainuosen Environmental Technology (langfang) Co., Ltd. Replacement PECO water filter P90-660-LSN-05L/MBUS$ 230 - 250MOQ: 10 PiecesXINXIANG Lefilter Filter CORP.LTD

Replacement PECO water filter P90-660-LSN-05L/MBUS$ 230 - 250MOQ: 10 PiecesXINXIANG Lefilter Filter CORP.LTD PECO Natural Gas Filter Element AFVG12US$ 5 - 30MOQ: 10 PiecesHenan Tianyu Purification Technology Co., Ltd.

PECO Natural Gas Filter Element AFVG12US$ 5 - 30MOQ: 10 PiecesHenan Tianyu Purification Technology Co., Ltd. Replacement Peco Facet aviation coalescer filter element CAA56-5SBUS$ 1 - 30MOQ: 5 PiecesXinxiang Lefilter

Replacement Peco Facet aviation coalescer filter element CAA56-5SBUS$ 1 - 30MOQ: 5 PiecesXinxiang Lefilter Peco coalescence filter element JPMG-4240-5AUS$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

Peco coalescence filter element JPMG-4240-5AUS$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS Peco Natural gas Filter element PZC336US$ 60 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

Peco Natural gas Filter element PZC336US$ 60 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS peco natural gas filter element FG-36US$ 60 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

peco natural gas filter element FG-36US$ 60 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS PECO coalescer & separator filter elements FG336US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

PECO coalescer & separator filter elements FG336US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS peco natural gas filters element FG-12US$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

peco natural gas filters element FG-12US$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS peco gas filter elements cartridge PCHG-12US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

peco gas filter elements cartridge PCHG-12US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS natural gas filter peco filter element fg-372-ceUS$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

natural gas filter peco filter element fg-372-ceUS$ 60 - 80MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS peco natural gas filter cartridge element PCHG-372US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

peco natural gas filter cartridge element PCHG-372US$ 70 - 90MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS FG-336 natural gas filter element cartridge pecoUS$ 50 - 70MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

FG-336 natural gas filter element cartridge pecoUS$ 50 - 70MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS peco gas filter elements PCHG-336 FG-372 FG-72 pchg-336-cUS$ 35 - 60MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS

peco gas filter elements PCHG-336 FG-372 FG-72 pchg-336-cUS$ 35 - 60MOQ: 10 PiecesGu\'an County Weiruiou Filter & Pufification Equipment Co., Ltd.5 YRS Replacement PECO facet CAA22-5 coalescer filter elementUS$ 1 - 30MOQ: 5 PiecesXinxiang Lifeierte Filter Corp., Ltd

Replacement PECO facet CAA22-5 coalescer filter elementUS$ 1 - 30MOQ: 5 PiecesXinxiang Lifeierte Filter Corp., Ltd