Digital panel meters equip data relevant toward modern industrial and commercial settings for exact measurement, control, and display. For voltage, current, temperature, or other important parameters, these compact instruments offer real-time information to enhance performance and efficiency. But what exactly are digital panel meters, and how do their application areas stretch through other industries like manufacturing, energy, and medicine? This blog settles the fundamentals of digital panel meters while discussing their primary features, types of uses, and enhancement of free-flowing operations. So, whether you are building on upgrading your existing setup or simply building on your understanding of these versatile instruments, this one-dive approach is yours. Get ready to learn how digital panel meters will draw a revolution in monitoring and managing data!

Introduction to Panel Meters

Defining and Purpose of Panel Meters

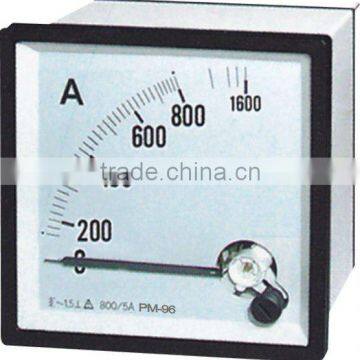

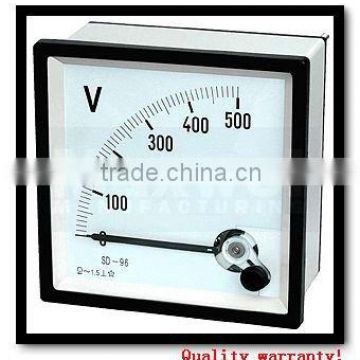

At the very basic level, panel meters are put in place to measure and display various electrical parameters that throw light on operations and health factors of electrical systems. These meters might be of the digital variety or analog variety and serve different applications. Digital panel meters offer much better precision and clarity while using LCD or LED displays to display data directly. Conversely, analog panel meters use needle indicators to represent a measurement and are preferred for the simplicity and ease of use they offer in some scenarios. Irrespective of whether they are digital or analog, the primary purpose remains to acquire an accurate measurement so that the parameters can be observed in real-time for balancing and control of the electrical systems for optimal operation and safety.

Types of Panel Meters

Panel meters can be generally divided into two types: digital and analog, with each type presenting certain benefits. Digital panel meters, designed for precision measurement and customization, are equipped with a host of resources such as programming options and serial communications. They commonly provide the users with the option to select decimal points, and backlit displays to assist readability and interactivity. Analog panel meters, however, are favored for being straightforward to use and robust, thus serving best in situations wherein a digital solution is not an option. Specialized meters, like load cell meters and frequency meters, address truly specialized needs for applications and supply solutions to specific measurement requirements. So, the broad selection of panel meters enables industries to pick the most suitable for their specific requirements, aiding in precision and operational efficiency.

Importance of Accurate Measurement

Electric measurements are certainly necessary for safety, efficiency, and reliability in systems. The panel meters are a significant part in accomplishing such measurements, as in providing accurate voltage, current, or any other parameter data that renders the system under observation useful. The problem in question can be very serious when deviations in such parameters occur even by a minimum in industrial applications; i.e., stoppages due to circuit malfunctions or processes being energy-inefficient. Employing digital panel meters with features such as programmable alarms and programmable relays to allow operators to be instantly informed of deviations and abnormalities and to implement corrective measures, thereby preventing further damage and downtime, consistent quality in the processes may be maintained. They also include measurements that help in decision-making, consequently allowing engineers and technicians to make considered choices towards the optimization of system performance and utilization of resources.

Digital Panel Meters

What Is a Digital Panel Meter?

A digital panel meter is an intelligent kind of instrument used for measuring and presenting parameters such as voltage, current, and frequency, where such parameters are numerically displayed by a measuring system. Traditional analog panel meters usually employ pointer-type indicators. A digital panel meter, in contrast, consists of an LCD or an LED display showing the measurement clearly and accurately. These meters make use of the input signal conditioning to effectively convert the detected values into digital numerical evidence. Digital panel meters qualify to receive and show a multitude of input signals, including dc voltage and dc current. Therefore, they have applications across a variety of fields. Being there is the general practice to mount these instruments in panels; hence, it is a crucial query in process control systems to make sure that parameters do not stray off specified limits and thus contribute to overall efficiency and safety. Setting parameters on such meters and programming their digital displays for varied effects, such as placement of decimal points, is an important feature that assists in accurate measurement and display.

Advantages of Digital Panel Meters

There are many advantages the digital panel meters have compared to the analog panel meters, and thus the former is increasingly favored in various industries. Highest on the list of advantages for accuracy and precision is of utmost importance in cases demanding monitoring of electrical parameters like voltage and current. With a digital-type display, more often LCD or LED, reading of indicated values is easy; hence, less human error. Moreover, such meters usually allow setting parameters through some programming, allowing connection to, and cooperation with, communication protocols of other devices in complicated control systems. Possible settings further include the choice of decimal points and setting of alarms and relay outputs to warn controls when there are parameter deviations permitted in standards. They also accept quite a large variety of input signals and voltage ranges, so they are good candidates for general measure applications. This is reassurance to the operator that the system shall have good input for well-timed decision-making for the enhancement of system efficiency.

Common Features of Digital Panel Meters

Digital panel meters have a range of features that enhance their capabilities and increase their ease of use. Commonly, they have a backlight, improving visibility under dim lighting or environments and ensuring readings are always within reach. In most digital panel meters, programming enables the user to customize the meter to the needs of the application, which can include engineering units and predetermined alarms that warn the operator if a variable gets too high or too low. These devices might accept many different signal inputs like analogue 4-20 mA input, hence increasing their application base. Most digital panel meters also support serial communication, allowing them to exchange data with other process control systems, thus adding to automated control capabilities. Heavy-duty meters commonly meet standards such as NEMA 4X, making them highly reliable in even harsh environments.

Applications in Various Industries

Use Cases in Automation and Control Systems

Panel meters are very important equipment in automation and control systems for ensuring proper and reliable operation. In such environments, the instruments used must show parameters such as voltage and current with the utmost accuracy. Generally speaking, they offer serial communication, can be programmed, and thus can work as a smart system within complex automation systems for real-time monitoring and control. The unit can keep an eye on the power supply, watching for fluctuations in voltage and current that are outside normal preset values so as to not damage any equipment. Warning and relay circuits are provided for giving immediate alarm if any deviation takes place, thus maintaining system integrity and performance. Also, with digital panel meters being used in automation systems, there can be an efficient utilization of resources on the basis of readings obtained, which enables companies to streamline their working processes and improve their operational efficiencies.

Panel Meters in Manufacturing and Process Industries

Panel meters have an important role in the manufacturing and process industries for quality control and manufacturing efficiency. Digital panel meters with their precise measurement capability are essential during processes that monitor and control the different stages of production. They can accept various input signals such as dc voltage and current to perform measurements of the machinery and equipment actuations involved. Keeping proper voltage and current levels in these industries is very important to keep production lines operating smoothly and to avoid time-consuming downtime. Programmable digital panel meters can be programmed by the manufacturer with specific parameters, and a warning will be activated whenever these parameters exceed set limits so that a timely intervention can be made. In addition, programmable panel meters, which are also provided with analog output, can continuously feed back measurements to control systems for auto compensation that stabilizes the process. By making sure that the production processes within the operation are functioning within set parameters, the panel meters ensure the best level of quality and efficiency in manufacturing.

Deploying the Panel Meter for Energy Management

In energy management, the meters really come into play by providing granular views of energy consumption and application for the corresponding optimization of energy demand. Digital panel meters become most real-time here as a means of highly accurate measurement and display of the parameters of electricity. Monitoring voltage and current at various points of an electrical network could allow energy managers to eliminate inefficiency and sharpen areas requiring remediation. Programmable features could allow for a personalized measurement, i.e., setting up of energy use thresholds, and an alarm would be triggered once the thresholds are exceeded. This is crucial in cutting back energy while also cutting back on operational costs. In addition, serially communicating digital panel meters allow track data to be transmitted to a central energy management system for extensive analysis and reporting. Using data given from the panel meters, organizations enhance operational efficiency, use less energy, lower their carbon footprint, and take the whole dilution of responsibility onward.

Frequently Asked Questions (FAQs)

What is a digital panel meter and how does it work?

A digital panel meter is an electronic device used to measure and display electrical parameters such as voltage, current, and resistance in a digital format. These meters often utilize an LCD panel for easy readability and can display multiple digits, allowing for precise readings. Many digital panel meters are designed to be panel mount for convenient installation in various applications. They can measure both AC and DC signals and are equipped with features like selectable ranges to accommodate different input voltages. Additionally, some models offer programmable settings, enabling users to customize the meter's functionality to their specific needs.

How does a voltage meter differ from a digital voltmeter?

A voltage meter typically refers to any device that measures voltage, which can include analog and digital types. In contrast, a digital voltmeter specifically uses a digital display to show voltage readings, often providing more accuracy and easier interpretation. Digital voltmeters can also feature advanced functionalities such as data logging and peak and valley detection. Many of these devices come with a backlight for visibility in low-light conditions and can be used for both DC voltage and AC voltage measurements. When selecting a voltmeter, it's essential to consider factors like input impedance and measurement range.

What are the advantages of using an LCD panel meter?

LCD panel meters offer several advantages compared to traditional analog meters. They provide clear, easy-to-read digital displays, which enhance visibility, especially in challenging lighting conditions. LCD panel meters can display multiple digits, allowing for more precise readings, and often include features like programmable settings and selectable measurement ranges. These devices are typically more durable and are designed for panel mount installations, making them suitable for industrial environments. Additionally, some models come with advanced functions such as voltage monitoring and data logging capabilities, which can be beneficial for process automation.

Can a digital panel mount meter be used for current or voltage measurements?

Yes, a digital panel mount meter is versatile and can be used for both current and voltage measurements. These meters often feature multiple input options, allowing users to select the measurement type needed for their application. For instance, some models can measure DC voltage, AC, or even process signals like 4-20mA. Many digital panel meters also come equipped with features like zero and span adjustment to calibrate the meter accurately. This flexibility makes them ideal for various applications in automation and industrial settings, ensuring they meet diverse measurement needs.

What is a programmable power meter?

A programmable power meter is an advanced type of panel meter that allows users to set specific parameters and thresholds for measurements. These meters can measure voltage, current, and power consumption, providing comprehensive data for monitoring electrical systems. With programmable features, users can customize how the meter responds to different conditions, such as setting alarms for high voltage or current levels. Many programmable power meters also include an LCD digital display for easy reading of real-time data. This functionality is particularly useful in applications where precise monitoring and control of electrical parameters are crucial.

How do I choose the right panel volt meter for my needs?

Choosing the right panel volt meter involves considering several factors, including the type of measurement needed (AC or DC), the range of voltage inputs, and specific features such as selectable measurement settings. It's essential to look for a meter with a high input impedance to minimize the impact on the circuit being measured. Additionally, consider whether you need an LCD panel for better visibility or a programmable option for advanced functionalities. Ensure that the meter meets the necessary compliance standards, such as NEMA ratings, for your application. Finally, check for additional features like data logging capabilities and user-friendly front panel buttons for ease of use.