panel board Insights & Buyer's Guide

Welcome to our hands-on guide to panel-board systems. Here, we'll break down the parts and uses that turn these boards into the backbone of both home and factory power flow. A clear grasp of panel-board details can help a homeowner, an industrial designer, or a small-business chief keep costs down while staying safe and passing local energy rules. Keep reading to see how the gear we carry can fit your setup and keep electricity moving the way you expect it to.

What is the Difference Between a Panelboard and a Switchboard?

Understanding Panelboard and Switchboard Components

Panel boards and switches are vital in transmitting electric current but vary in his or her usage. As the name suggests, a panel board is mainly installed in building premises to control current supplies into and from branch circuits. In most cases, it has circuit breakers and is installed on the wall for the ease of accessing it, and the ease of loading and maintenance. However, switchboards are made bigger, whereby their structure serves as a means of electrical power distribution within a specific industry and or business to the user level. Often, they can carry many loads and are thus employed in many cases to supply a university lab with electricity, with the many panel boards or other distribution instruments. It is very important to remember these points to be able to choose from these electrical distribution items the one that suits your purposes.

Applications of Panelboards in Home and Industrial Settings

Panelboards pop up in all sorts of places, from a two-bedroom ranch to a sprawling factory floor. Inside a typical house, a lighting-appliance board shares juice with lamps, heaters, and the never-ending parade of gadgets we all depend on. Switch the scene to an industrial plant, and roughly the same box steers current toward motors, pumps, and any other iron that keeps the line moving. Custom specs often drive the build, so each board clears the safety checks that its trade or zone demands. Small bungalow, mega factory, or anything in between, you rarely find a modern electrical system that can skip this workhorse.

The Role of Switchboards in Large Power Distribution Systems

A switchboard is usually the beating heart of an industrial or commercial power system. Picture it as the traffic tower that directs every stream of electricity flowing from one neighborhood to another. Because it handles heavy voltage and thick currents, the board is built like a mini fortress- safety enclosures, heft fuses, and circuit breakers galore. Thanks to that muscle and design smarts, a single board can keep the lights on while stopping nasty overloads from turning the breaker yard into a fireworks show.

How to Design a Panel Board for Your Project?

Key Considerations for Panel Board Design

Building a good panel board isn't just a box-ticking exercise- it's the nerve center of your whole electrical plan. Step one is figuring out how much power the system will swallow, branch by branch, circuit by circuit. If the numbers don't line up, the gear you buy will either overheat or sit idle and be expensive. Pick breakers and panelboards that match those load calculations and still play nice with local codes and energy rules. Sweat those details now, and the finished board will handle your project's quirks without breaking a sweat.

Choosing the Right Enclosure and Mounting Options

The enclosure and mounting options are critical aspects of panel board design, affecting both the functionality and safety of the system. The enclosure should provide adequate protection against environmental factors, especially in hazardous areas or industrial settings. It should also allow for easy access to the interior components for maintenance and inspection. Mounting options vary depending on the application, with wall-mounted and floor-mounted options available. Selecting the right enclosure and mounting ensures that your panel board is both secure and accessible.

Integrating Series Ratings for Enhanced Protection

Series ratings give panel boards a useful boost by letting them ride out big short-circuit hits without frying. When the rating is wired in correctly, the board keeps power flowing and saves itself from nasty damage. That level of dependability matters even more on sprawling power grids, where giant fault currents are the norm. A strong series rating acts like a built-in guardrail, slowing down overloads and keeping the whole network stable. Figuring out the right series number for any given installation is one of the first homework problems an engineer tackles.

What Are Lighting and Appliance Panelboards?

Features of Lighting and Appliance Panelboards

Lighting and appliance panelboards are mainly used in households to distribute electricity to lighting and other appliances in the house. They contain different breakers and control features that allow the loads to be managed effectively and safely. These panelboards are designed to be small in size and can fit seamlessly in a household electrical setup. The ability of lighting and appliance panelboards to carry many circuits, provide current overload protection, as well as facilitate work in buildings that have energy codes, is the major advantage. These features form the basis of their application in residential buildings.

Benefits of Using Lighting and Appliance Panelboards in Homes

The utilization of lighting and appliance panelboards in residences comes along with several advantages, such as for example increased safety, efficiency, and convenience. They offer a central point for the distribution of power for various circuits, which also eliminates the excesses and other electrical dangers. They also enable the homeowner to control their energy use with ease, which translates to cost savings and conforming with current energy regulations. Furthermore, lighting and appliance panelboards improve the overall performance of the electrical network in the residence, providing a more stable and effective operation of the lighting and appliances.

Installation Tips for Lighting and Appliance Panelboards

The correct and safe installation of lighting and appliance panel boards is important mainly due to their performance. The installer is required to install the device according to the recommendations of the manufacturer and best practices set out in the concerned industry. The panel board is supposed to be located in an area that is accessible, clean, and tidy. Every termination should be checked for tightness and also well aligned to avoid any electrical discharges. Additionally, there should be periodic checks and maintenance carried out in order to ensure that the panelboard is still working effectively and safely. With these installation tricks, you will be able to enhance the operational functionality of your lighting and appliance panelboards as well as stretch their lifespan.

How to Achieve Safety and Standard Compliance in Panel Board Systems?

Know the Safety Standards and Regulations

No more evidence is needed to understand how crucial it is to comply with safety standards and rules in designing and using panel board systems. Such requirements, such as the National Electrical Code (NEC) in the U.S, guide how electrical equipment and systems should be distributed and protected safely. It is imperative to grasp these restrictions so that your panel board system can be built in a manner that does not allow any electrical risks, such as overloading or short circuit. This is because adherence to safety standards is not only effective in safeguarding your property and people but also in improving the efficiency and reliability of the electrical distribution system.

Load Distribution and Protection in a Safe Manner

It is important to note that load distribution and protection as per safety standards are mandatory for the operation of panel board systems. This includes carrying out the calculation of branch circuit requirements accurately to determine the panel boardβÄôs load-carrying capacities and ensuring that the total load does not exceed the capacity of the panel board. Devices such as breakers should be chosen according to the requirements of the system so as to provide adequate protection in case of an overload or a fault. In this manner, it is possible to increase both the safety and reliability of the electrical distribution system.

Safety Assurance through Periodic Maintenance and Execution of Inspection

There is an inevitable requirement for regular maintenance and inspection if any panel board system is to remain safe and effective over time. Inspections allow spotting of potential problems early, before integrating them into the system irreversibly, and facilitating repairs or interventions when necessary. Maintenance activities should be carried out, including the checking of all the connections, testing of breakers, and ensuring that the panel board is installed within the current safety standards. Therefore, to safeguard efficiency, safety, and adherence to all relevant standards, maintenance and inspection of the panel board system must be scheduled routinely.

Frequently Asked Questions(FAQs)

Q: What is a panel board system?

A: A panel board system, also known as a distribution panelboard, is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure.

Q: How does a circuit breaker function within a panel board?

A: A circuit breaker within a panel board acts as a safety device designed to protect an electrical circuit from damage caused by overload or short circuit. Its basic function is to interrupt current flow after a fault is detected.

Q: What factors should be considered when determining the location for a panel board?

A: When determining the location for a panel board, consider accessibility for maintenance, compliance with electrical codes, the proximity to the main power supply, and the interior layout of the building. A consultant can provide expertise in selecting the optimal location.

Q: What is the role of the trim in a panel board?

A: The trim in a panel board serves as a protective cover that conceals the internal components, such as the chassis and breakers, providing safety and a finished appearance to the distribution equipment.

Q: How does the manufacturing process impact the quality of panel board systems?

A: The manufacturing process impacts the quality of panel board systems by determining the durability, safety, and performance of the product. High-quality materials and precision engineering ensure reliable distribution equipment that meets industry standards.

Q: What is the role of a feeder in a panel board system?

A: A feeder in a panel board system is a set of conductors that supply electrical power from the main distribution panelboards to subsidiary circuits, ensuring the efficient transfer of electricity throughout the building.

Construction Materials Waterproof Acoustic Lightweight Aluminium Ceiling Panels BoardUS$ 1.35 - 1.58MOQ: 500 Square MetersShanxi Pano Building Materials Co., Ltd1 YR

Construction Materials Waterproof Acoustic Lightweight Aluminium Ceiling Panels BoardUS$ 1.35 - 1.58MOQ: 500 Square MetersShanxi Pano Building Materials Co., Ltd1 YR Eco-Safe PP Hollow Board Tree Protectors βÄ?Long-Lasting Growth PanelsNegotiableMOQ: 3000 PiecesZibo Shichuang Composite Materials Co., Ltd.1 YR

Eco-Safe PP Hollow Board Tree Protectors βÄ?Long-Lasting Growth PanelsNegotiableMOQ: 3000 PiecesZibo Shichuang Composite Materials Co., Ltd.1 YR PMMA Raw Material for Electronic Boards Audio Panels Acrylic Medium Viscosity PMMAUS$ 1.9 - 2.05MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS

PMMA Raw Material for Electronic Boards Audio Panels Acrylic Medium Viscosity PMMAUS$ 1.9 - 2.05MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS insulation panel boardNegotiableMOQ: 300 Square MetersYifeng Clean Technology Jiang Su Shares Co., Ltd.5 YRS

insulation panel boardNegotiableMOQ: 300 Square MetersYifeng Clean Technology Jiang Su Shares Co., Ltd.5 YRS paulownia panel board partsUS$ 350 - 500MOQ: 5 Cubic MetersDongming Sanxin Wood Industry Co., Ltd.5 YRS

paulownia panel board partsUS$ 350 - 500MOQ: 5 Cubic MetersDongming Sanxin Wood Industry Co., Ltd.5 YRS melamine mdf panel boardUS$ 250 - 355MOQ: 28 Cubic MetersLinyi Seasong International Trade Co., Ltd.5 YRS

melamine mdf panel boardUS$ 250 - 355MOQ: 28 Cubic MetersLinyi Seasong International Trade Co., Ltd.5 YRS wpc wall panel boardUS$ 12 - 18MOQ: 200 Square MetersHaining Shamrock Import & Export Co., Ltd.5 YRS

wpc wall panel boardUS$ 12 - 18MOQ: 200 Square MetersHaining Shamrock Import & Export Co., Ltd.5 YRS galvanized panel board steel lockersUS$ 5 - 189MOQ: 5 SetsShanghai Rongyan Logistics Equipment Co., Ltd.5 YRS

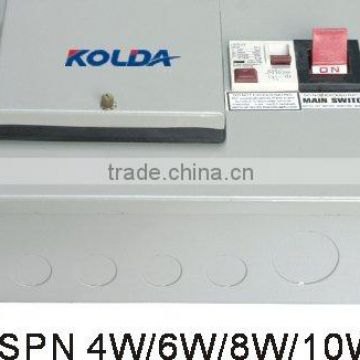

galvanized panel board steel lockersUS$ 5 - 189MOQ: 5 SetsShanghai Rongyan Logistics Equipment Co., Ltd.5 YRS Korea technology waterproof panel boardUS$ 1,000 - 50,000MOQ: 1 SetLongkou Unity Machinery Equipment Co., Ltd.5 YRS

Korea technology waterproof panel boardUS$ 1,000 - 50,000MOQ: 1 SetLongkou Unity Machinery Equipment Co., Ltd.5 YRS plastic machine control panel boardUS$ 0.05 - 0.3MOQ: 500 PiecesDongguan Shunding Hardware Products Co., Ltd.5 YRS

plastic machine control panel boardUS$ 0.05 - 0.3MOQ: 500 PiecesDongguan Shunding Hardware Products Co., Ltd.5 YRS ACP (Aluminium Composite panel board)US$ 4 - 40MOQ: 800 Square MetersFoshan Vanco Building Materials Co., Limited5 YRS

ACP (Aluminium Composite panel board)US$ 4 - 40MOQ: 800 Square MetersFoshan Vanco Building Materials Co., Limited5 YRS Supply Cinema Acoustic panel boardUS$ 20 - 50MOQ: 100 Square MetersGuangzhou Liyin Building Material Co., Ltd.5 YRS

Supply Cinema Acoustic panel boardUS$ 20 - 50MOQ: 100 Square MetersGuangzhou Liyin Building Material Co., Ltd.5 YRS mens contrasted panels board shortsUS$ 2.2 - 5.8MOQ: 1500 PiecesXiamen Dukai Industry & Trade Co., Ltd.5 YRS

mens contrasted panels board shortsUS$ 2.2 - 5.8MOQ: 1500 PiecesXiamen Dukai Industry & Trade Co., Ltd.5 YRS Fiberglass FRP Sandwich panel boardUS$ 2 - 20MOQ: 500 MetersSanchuang FRP Products Factory In Shipai Town Dongguan City5 YRS

Fiberglass FRP Sandwich panel boardUS$ 2 - 20MOQ: 500 MetersSanchuang FRP Products Factory In Shipai Town Dongguan City5 YRS 2014 new car panel board lighting displayUS$ 15 - 99MOQ: 100 PiecesZhengzhou Zeyeng Electronic Technology Co., Ltd.5 YRS

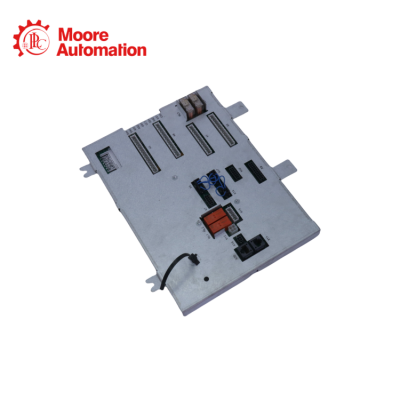

2014 new car panel board lighting displayUS$ 15 - 99MOQ: 100 PiecesZhengzhou Zeyeng Electronic Technology Co., Ltd.5 YRS Contract Manufacturing Electrical Control panel board AssemblyUS$ 0.18 - 1.58MOQ: 100 PiecesShenzhen Moko Technology Ltd.5 YRS

Contract Manufacturing Electrical Control panel board AssemblyUS$ 0.18 - 1.58MOQ: 100 PiecesShenzhen Moko Technology Ltd.5 YRS Promotion Gift For Christmas LED Kids panel boardUS$ 10 - 50MOQ: 100 PiecesHenan Zailushang Import & Export Trading Co., Ltd.5 YRS

Promotion Gift For Christmas LED Kids panel boardUS$ 10 - 50MOQ: 100 PiecesHenan Zailushang Import & Export Trading Co., Ltd.5 YRS studio wall foam sponge panel boardUS$ 8 - 20MOQ: 500 Square MetersFoshan Tiange Acoustic And Decor Material Co., Ltd.5 YRS

studio wall foam sponge panel boardUS$ 8 - 20MOQ: 500 Square MetersFoshan Tiange Acoustic And Decor Material Co., Ltd.5 YRS custom logo printing foam panels acoustic panel boardUS$ 10 - 12MOQ: 100 PiecesNangong Huizhong Felt Products Co., Ltd.5 YRS

custom logo printing foam panels acoustic panel boardUS$ 10 - 12MOQ: 100 PiecesNangong Huizhong Felt Products Co., Ltd.5 YRS opal pvc foam panel with good quality pu sandwich panel boardNegotiableMOQ: 1 TonXingtai Changshuo Auto Parts Co., Ltd.5 YRS

opal pvc foam panel with good quality pu sandwich panel boardNegotiableMOQ: 1 TonXingtai Changshuo Auto Parts Co., Ltd.5 YRS Wholesale MDF Slatwall Slotted Wood Panel/Board for StoresUS$ 12 - 17MOQ: 100 PiecesGuangzhou Beautiful Hardware Manufacture Ltd.5 YRS

Wholesale MDF Slatwall Slotted Wood Panel/Board for StoresUS$ 12 - 17MOQ: 100 PiecesGuangzhou Beautiful Hardware Manufacture Ltd.5 YRS www.xx.com China Outdoor P10 Red/R LED Panel/BoardUS$ 168 - 168MOQ: 1 Square MeterJiangsu JD Electronics Co., Ltd.5 YRS

www.xx.com China Outdoor P10 Red/R LED Panel/BoardUS$ 168 - 168MOQ: 1 Square MeterJiangsu JD Electronics Co., Ltd.5 YRS