gloss meter Insights & Buyer's Guide

Gloss meters are important in evaluating various materials’ surface gloss and reflectance. Uniquely, this instrument is a must-have in industries that focus on the look of the product and quality of the processes themselves. Manufacturing, car making, and furniture making are some of those industries. Its objective is to measure the gloss levels by measuring the specular light directed to a surface with all its components. It also provides a tool that supports maintaining defined variation levels of gloss, which is preferable and acceptable to the client in the finished product.

The measurement of gloss is a measurement of the amount of light reflected from the object's surface at a given angle. Classified by gloss level from low to high gloss finish, that is, without looking at the range extension, commonly used angles are 20°, 60°, and such extreme angle – 85°. However, it is not uncommon to use 60° as this angle serves most ordinary purposes and provides a depiction of glossiness. However, for high gloss surfaces, wooden and laminated types, 20-degree geometry is used since small changes can be captured. These three angles are normally integrated in the micro tri gloss or three-angle gloss meter, which provides a 360-degree gloss analysis of the surface.

From the above, it is clear that when making measurements using a gloss meter, one should respect the concept of calibration and precision, ensuring that what is read represents an actual value of gloss. For that reason, instrumentation has to be set by international standards such as ASTM D523 and/or ISO 2813 to ensure that the unit of gloss, gloss units (GU), remains consistent and accurate. Such standards also define the appropriate angle and condition for testing gloss so that quality assurance in different industries can be done easily. More importantly, most modern gloss meters, some with a USB port that can store data, can be carried to places when needed or during continuous evaluation of surface profiles, which mainly contributes to their importance.

Researching Gloss Meters

Cloud-Defined Conspectus of a Gloss Meter

A gloss meter is a surface shine measuring device that helps to determine accurately the parameters of reflection of the object surface. It works by estimating the specular light reflection off a surface at a given angle, thereby supplying gloss units (GU) that characterize how bright or dull the given surface is. This is a tool that, industry-wide wide can be found necessary in automobile production, furniture fabrication encounters, amongst others, where gloss level has to be maintained at a certain level for quality control and services. The use of gloss meters is not only concerned with decorative purposes but also with the integrity of the film/casting and evaluating the usage of the material (s) depending on the qualitative characteristics of the surface.

Gloss Measurement Process

It is the process by which a gloss meter sends a beam of light to the specified angle on the surface and reads back the amount of light that is reflected or absorbed. It is 20, 60, and 85 degrees, and each angle has an appropriate end use for specific gloss ranges. For example, a 60° angle is a general-use measurement, while a 20° angle should be used to accommodate any minor changes in high gloss surfaces, and the 85° angle is for low gloss surfaces. Such angles are pivotal as they help position the gloss meter to cover gloss in all finishes, achieving a wide range of assessments. In other words, a gloss meter can convert gloss potential in reflected rays into gloss units, especially because industries need to maintain a uniform product quality over time. Calibrations performed according to international rules and regulations like ASTM D523 and ISO 2813 are very important because they ensure readings are correct as well as normalized to the international models.

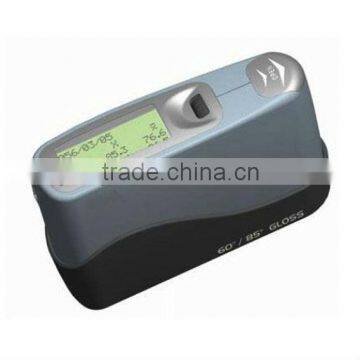

Single Angle or Three Angle Gloss Meter

There are many types of gloss meters out there, but typically, gloss meters fall into single-angle or three-angle categories. Single-angle glossmeter, as the name suggests, measures gloss in one angle; the majority of them are 60°, which is used for general-purpose measurement of gloss on various surfaces. On the other hand, three three-angle gloss meter, like micro-tri-gloss, is useful for more extensive analysis. It measures gloss on three angularities, 20°, 60°, and 85°, enabling richer information on the changes in gloss depending on the type of finish (matt, semi-gloss, and high gloss) that is used. The 3-angle gloss meter was developed due to requirements in certain industries where multiple geometry gloss analysis is needed for evaluation of gloss in fine details that would otherwise not have been noticed with a single-angle instrument. Having an expanded range of measurements along with several angle gloss analyses, three-angle gloss meters are of utmost necessity while making sure quality is maintained in products and the strictest standards are adhered to.

Applications of Gloss Measurement

Automotive Industry: Importance of Surface Finish

The automotive industry is highly dependent on the surface finish of the car as it has both decorative and practical aspects. It would be impossible to do without any gloss meter, especially the three-angle gloss meter with its high accuracy. It is used in measuring the colored coatings of automobile paints and paints. Due to the ability to measure gloss at angles of 20°, 60°, and 85°, each detail on each vehicle produced will retain an identical and homogenous gloss level. Which is very important for the increase of brand image and customer satisfaction since differences in gloss, even so small, might be too obvious. Also, in order to keep up with the thickness of paints and ensure consistency, it is believed that gloss meters enable the manufacturers to check the thickness of the gloss applied. This extreme concern over gob helps address problems with haze and ensures that the product is high quality and serves aesthetic as well as functional purposes.

Manufacturing: Ensuring Quality Control

The importance of gloss measurement is greater in the manufacturing industry when it comes to quality control, as every product should fall within a prescribed gloss range. Both single-and and three-angle gloss meters are used to determine the gloss level of plastic products, metallic objects, and ceramics, among others. These machines give manufacturers the confidence that the glossiness of each product meets the set standards and positions, including all batches of production. Using a gloss meter at the production stage helps the producers spot and rectify any unusual levels of gloss, i.e., before suspending manufacturing for retouching the products and wasting them. The calibration of the gloss meter as per the standards mentioned earlier (ASTM D523) is very important so that linear and consistent results can be obtained and maintained, resulting in products of high quality and satisfying customers.

Furniture Production: Aesthetic and Functional Aspects

In the furniture production industry, gloss measurement has both decorative and functional connotations, and it is an important aspect that influences the look and quality of the products. In this context, furniture manufacturers gloss meters to degree glossiness of all the finishes from flat gloss to super gloss in order for every element to satisfy certain other forms or expectations as to the surface of an object. In this regard, the inclusion of a three-angle gloss meter, for instance, a micro-tri-gloss, is useful in the evaluation of the surface finish because it picks up the changes in the gloss, for instance, the one that affects the final product. Glossiness is not only for the look of the furniture but also assists in the evaluation of an item’s durability and the quality of the coating to ensure that each of the items can be used at the same time and continues to be attractive. Many furniture manufacturers employ global measurement standards to a greater extent, so the items they produce, while pretty, cannot attract the customer alone; they must serve them functionally also.

Practical Tips on the Use of a Gloss Meter

Calibrating Methodology to Get a Uniform Result

Calibration is one of the key aspects of a gloss meter that helps obtain similar readings in the process of gloss measurement. It is the process of tuning the equipment to make accurate and repeatable gloss measurements. One must periodically calibrate, for example, according to ASTM D523 and ISO 2813, for the purposes of getting the gloss meter to go along with sensible expectations. In the calibration process, it is very important to have an appropriate reference standard concerning the gloss level of the items that you normally measure. For instance, if you tend to concentrate on specific glosses such as High finishes, then a high gloss calibration standard shall suffice. The meter should then be set at the appropriate angle of 20°, 60°, or 85°, as per the surface being measured, before any measurements are taken. To capture all this reflectance information as specular reflections, this is the preparation step that is required. Lastly, one advantage of using a gloss meter with USB connecting ability is that it makes you forget all about those calibration processes because you can download data into the gloss meter to confirm the calibrations. With the help of strict and controlled calibration, users of the gloss meter are able to maintain the uniformity of the readings across various applications of the gloss meter.

Methods that Work Well in Low-Gloss Surfaces Evaluation

Several techniques aid in ensuring that low-gloss surfaces are accurately measured. It is recommended to use a three-angle gloss meter consisting of 20, 60, and 85 degrees when dealing with surfaces that do not reflect as much, such as matt finishes. 85° beam is the best gloss meter angle when measuring low gloss surfaces since it is able to detect any slight increase in surface gloss, thanks to its broader range. As well, the surface should be measured first, and it should not have any dirt or other impurities that can affect the gloss measurement. The position of the gloss meter should be such that the measurement is done at a direct angle to the surface. Any level of haze that may exist that can affect the gloss readings must also be taken into account. Enforcing calibration with a low-gloss calibration standard check ensures the accuracy of the measurements over time. There are also merits in taking several measurements in different areas of the same surface so that the gloss level can be fully evaluated. By following these best practices, users achieve accurate, consistent gloss measurement results and ensure that the final product meets the desired aesthetic and functional criteria.

Data analysis: Interpreting gloss measurement results

Interpretation of results after gloss readings have been taken is one of the most important procedures in the use of the gloss meter. The data collected must then be transformed into useful information about that surface’s gloss condition. The gloss level measured by the gloss meter available in gloss units (GU) is an objective gloss measurement that can be related to industry practices or specific projects. While processing the results, it is always necessary to pay attention to which measurement angle, was it 20°, 60°, or 85°, was used and which gloss levels can be detected at each of these angles. For example, the 20-degree measuring angle is recommended for high gloss surfaces; however, measuring at 85 degrees is favorably used for low gloss surfaces. Such understanding is important for the proper interpretation of results. Furthermore, examine the data for any trends like uniform glossing or variations that are not expected and might indicate some problems with the coating or surface preparation. Taking advantage of newly developed gloss meters with some advanced features, such as USB data transfer, it is very easy to compile and analyse data for thorough analysis. A serious elaboration of the data makes it possible to maintain the quality control and to provide the necessary information that the end consumers require, and that is the required quality of the surface finish.

Frequently Asked Questions (FAQs)

What is a gloss meter, and how does it work?

A gloss meter is an instrument used to measure the glossiness of a surface, providing quantitative data on how shiny or reflective a material is. It works by shining a light beam onto the surface at a specific angle and measuring the amount of light that is reflected. The results are typically expressed in gloss units, which can help in quality control and product evaluation in industries such as automotive, coatings, and plastics. By using a gloss meter, manufacturers can ensure that their products meet the required aesthetic and functional standards. It is essential for applications where the appearance of a surface is critical, such as in finishes and paints.

What are the different types of gloss meters available?

There are several types of gloss meters, including handheld gloss meters, benchtop gloss meters, and portable models. Handheld gloss meters are convenient for field testing, while benchtop models are used for more precise laboratory measurements. Each type is designed for specific gloss measurement ranges, such as low, medium, or high gloss surfaces. Some gloss meters can also measure gloss at multiple angles, allowing for a more comprehensive analysis of surface reflectivity. The choice of gloss meter often depends on the application and the level of accuracy required.

How do I choose the right gloss meter for my needs?

Choosing the right gloss meter involves considering several factors, including the type of surfaces you will be measuring and the gloss levels you need to assess. If you work with a range of materials, a multi-angle gloss meter may be ideal to capture varying gloss levels accurately. Additionally, consider the portability of the device if field testing is essential. Look for a model that provides calibration options to ensure accuracy over time. Finally, consider the manufacturer's reputation and customer support, as reliable service can be crucial for maintenance and troubleshooting.

Can gloss meters be used for all types of surfaces?

Gloss meters can be used on various surfaces, but their effectiveness can vary based on the material's texture and finish. Smooth surfaces, such as glass and polished metals, generally provide more accurate readings compared to rough or uneven surfaces. Some gloss meters are specifically designed to measure the gloss of textured or matte finishes, while others may struggle to provide consistent results on such surfaces. It is essential to select a gloss meter that matches the specific surface characteristics of the materials you intend to measure. Additionally, using the appropriate calibration standards can help achieve reliable results across different surface types.

What industries commonly use gloss meters?

Gloss meters are widely used in various industries, including automotive, coatings, plastics, and printing. In the automotive industry, they help ensure that paint finishes meet aesthetic standards, while in coatings, they are crucial for quality control during production. The plastics industry relies on gloss meters to assess the surface quality of products, ensuring they meet consumer expectations. Additionally, the printing industry uses gloss meters to evaluate the sheen of printed materials, enabling manufacturers to maintain consistency in their products. Overall, gloss meters play a vital role in maintaining quality across multiple sectors.

digital stone gloss meterUS$ 100 - 500MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

digital stone gloss meterUS$ 100 - 500MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. WG68 marble gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

WG68 marble gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. Handheld Digital gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

Handheld Digital gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. Precision gloss meter WG60US$ 100 - 266MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

Precision gloss meter WG60US$ 100 - 266MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. gloss meter serial WG60US$ 100 - 266MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

gloss meter serial WG60US$ 100 - 266MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. WG68 Precision gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

WG68 Precision gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. high precision gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

high precision gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. printing ink gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

printing ink gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. WG68 marble gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

WG68 marble gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. good stability gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

good stability gloss meterUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. gloss meter for paintUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

gloss meter for paintUS$ 500 - 1,070MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. high accuracy gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

high accuracy gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. digital stone gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

digital stone gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. multi angle gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

multi angle gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd. WG60A paint gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.

WG60A paint gloss meterUS$ 100 - 486MOQ: 1 SetChangsha Shuangxin Measurement Technology Co., Ltd.