Transform your business today with the Fiber Laser Cleaning Machine, a new wave in cleaning technology that redefines the term “clean”. The laser technology utilizes unmatched precision and efficiency, turning multifaceted tasks into seamless processes. Industries with demanding standards for cleanliness and surface integrity require tools with unmatched sophistication. Fiber laser systems are transforming the way we do business around the globe. If you are looking for more information about Fiber Laser Cleaning Machine - UDTECH go here right away.

Laser cleaning technology Fiber laser cleaning machine is equipped with one of the most advanced and works at a professional level. Cleaning with a laser consists of focusing high-power light beams onto a surface and removing certain contaminants while not damaging the core material. Sensitive and delicate materials can be cleaned to a higher standard while being treated with a non-contact approach using this method. Compared to chemical cleansing techniques, this method is much more accurate while being less intrusive and easier to implement.

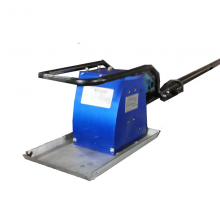

The operation of fiber laser cleaning systems is rooted in producing focused laser beams which locally scrub corroded surfaces such as rust, paint, and oxidic layers. For scrubbing purposes, painting or rusted over metals, the pulse laser can adjust to different settings and be finely supplied with energy which makes it possible to remove such unwanted substances without harming the underlying material. The cleaning of handheld lasers increases mobility, meaning these devices can be taken to different settings within the same work environment.

Once again looking at efficiency, surroundings, and adaptability, The Fiber Laser Cleaning Machine stands out due to Eye Clean, Inc.’s innovations. Unlike traditional techniques that utilize some form of abrasive technique or strong cleaning materials, fiber laser cleaning is safe and does not destruct items. It is particularly useful in applications that need to be cleaned thoroughly like aerospace, automotive, and restoration of ancient objects. Its accuracy in the removal of contaminants is what makes it popular in modern industries.

Fiber laser cleaners offer great benefits in precision, speed, and lower manpower expenditures laser cleaning rust and other forms of cleaning. It augments the retrieval process by clearing rust at a rapid pace while safeguarding the parts’s structural integrity. It is devoid of putting painstakingly tiring work every day manually and also hazardous materials so operators as well as the surroundings are fortunately safe.

Cuts and bruises to the surfaces, tools of coordination exercises together with chemicals prone to toxic fumes are among the attributes which characterizes traditional rust removal procedures. Arduino controlled lasers provide adequate accuracy and efficiency, leaves no filth behind and does not endanger the surface in any manner. The technique guarantees that only the specified areas are acted upon while the rest remains as untouched material. It works with remarkable accuracy as far as boundaries are concerned.

Yes, and with handheld laser cleaners rust can be removed easily. These devices are not only portable, but with portability comes a lot of accessibility and convenience. With the guarantee that they will be working in odd environments, and complex structures, handheld laser rust removers work vigorously and consistently regardless of the size and surface thereby making them important devices for maintenance and restoration work.

The cleaning of extremely stubborn contaminants using the 2000w machine is done with effortless ease because of the high power output. The machine is a good fit for large industrial cleaning jobs, removing tough barriers like rust, paint, soot and baked grease.

The laser cleaning machine is perfectly designed for heavy industrial use and can stand up to the toughest of environments without compromising its performance. The unit's intense laser beam and superb Ablation abilities ensure both optimal surface preparation and timely execution. Thus, it becomes a requirement in turbulent environments like shipping and construction due to its unparalleled cleaning adaptability.

The effectiveness of the 2000w laser is unmatched. Be it metals or composites, its cleaning is made easy because of the unparalleled precision provided on varying laser outputs, allowing different grades of cleanliness required depending on how fragile the exposed surface is. The precision of a fiber laser is unbeatable as it allows for blanket adaptation to multiple materials, making each job distinctly user-friendly, tailored to particular substrate Cleansing needs.

Due to their unparalleled accuracy in contaminant removal, fiber laser cleaning systems are widely adopted in aerospace, automotive, electronics, and manufacturing industries. They are also of great importance in restoration work where historical artifacts and other object of significance are restored without altering their original state.

Laser cleaning can effectively get rid of a wide-ranging list of contaminants such as rust, oxides, paint, and other surface impurities. The precision of laser cleaning guarantees the removal of even the most minute particles of contamination, something traditional methods do not offer. Fiber lasers, for example, excel in addressing multiple contamination issues which makes them useful for different types of cleaning.

Laser cleaning is fundamental in the automotive industry when it comes to removing paint, ablating rust, or cleaning base surfaces prior to welding and bonding. It results in surfaces that are free of residues, which is critical for thorough assembly and finishing. Improvement in production efficiency occurs by enhancement of cleanliness and the reduction of preparation time.

Operators are kept safe with the inclusion of a number of steps within the laser systems which include: protective enclosures, safety interlocks, and shuttering control systems that control and protect from dangers of high powered laser beams.

When cleaning with lasers, a non-contact cleaning technique is used to avoid damaging the base of the item being worked on. Using lasers with care ensures that only contaminants are removed, without altering the finish or surface level.

The use of lasers for cleaning increases environmental protection when compared to cleaners since there is no need for chemicals or production of waste. These lower is not only help the environment, but also reduce operational costs for the company which is most eco-friendly.

A: A fiber laser cleaning machine is a type of cleaning equipment that uses a laser source to remove contaminants like rust and paint from metal parts, surfaces, and other materials. It is known for being a cost-effective and faster cleaning solution compared to traditional methods.

A: A laser cleaning machine works by emitting a high-intensity laser beam from a cleaning head onto the surface that needs to be cleaned. The laser ablation process removes rust, paint, and other unwanted layers without damaging the underlying material. This method is effective for various cleaning needs.

A: A portable handheld laser cleaning machine offers several advantages, including easy transportation, flexibility in cleaning hard-to-reach areas, and the ability to handle diverse surface cleaning tasks. It reduces downtime and increases efficiency in maintenance and cleaning operations.

A: Yes, laser cleaning solutions are suitable for cleaning delicate and historical relics, as they provide precise surface treatment without causing damage. The optical precision of the laser source ensures that even intricate details are preserved.

A: Laser cleaning is highly effective for auto parts as it efficiently removes contaminants such as rust and paint, preparing surfaces for further processing like laser welding. It helps in maintaining the quality and performance of the parts.

A: A laser cleaning machine can remove a wide range of contaminants, including rust, paint, oil, and varnish. It is also effective for laser paint removal and cleaning rubber mold surfaces.

A: The cleaning speed of a laser is significantly faster compared to mechanical cleaning methods like sandblasting. Laser cleaning offers higher cleaning efficiency while reducing maintenance costs and avoiding surface damage.