An earthing system is a safety lifeline for any electrical setup. It links wires and gadgets directly to the ground, giving runaway fault currents a place to drain off. When that link is solid, people stay safe and gear avoids costly damage during power spikes. Knowing the main earthing styles and how each one is wired lets you keep your circuits both reliable and secure.

What is an Earthing System and Why is it Important?

An earthing system, often called grounding in some places, is a must-have for any electrical setup. It acts like a safety valve by giving errant fault currents a quick, low-resistance route straight into the ground. Because of that quick exit, scary voltages don't hang around on metal parts you might touch, cutting down the chances of a nasty shock. A good earth connection also keeps voltage levels steady across the network, letting everything run the way it was meant to.

Components of the Earthing System

Every earthing or grounding system really boils down to three simple parts: electrodes, conductors, and wires. Earth electrodes, usually metal rods or plates buried below the surface, make that all-important physical link to the soil. Earth conductors then carry current from those electrodes back to the main electrical panel, keeping the system tidy. Grounding conductors finish the job by connecting the neutral line and any protective gear directly to the ground. When stacked together, these pieces minimize shock risk and help clear electrical faults fast.

How Does an Earthing System Protect Against Faults?

Earthing systems play the solid role of steering dangerous fault currents straight into the ground. Imagine a sudden short circuit; the surge shoots down the earthing wires until it hits the buried earth electrode, skipping over delicate gadgets and giving them a fighting chance. That quick diversion also keeps the voltage cozy and normal inside the supply lines, sparing the wiring from a shocking spike that could ruin everything.

Role of the Grounding Conductor in Safety

A grounding wire is your number-one safety feature in an electrical setup. When everything is working right, it connects the whole system directly to the soil. If a short circuit happens, the wire shuts down the rogue current into the ground instead of letting it creep through circuits, tools, or even worse-you. By bonding the neutral line and the protective wire to that same earth point, the setup keeps high voltage spikes from ruining equipment or flipping lives upside down.

How Do Different Types of Earthing Systems Work?

Different types of earthing systems, such as TN, TT, and IT, offer varying levels of protection and are chosen based on the specific requirements of the electrical installation. Each system has its unique configuration and method of connecting to Earth, influencing how fault currents are managed and dissipated.

Exploring TN, TT, and IT Earthing Systems

The TN setup-TN-C, TN-S, or TN-C-S hooks the neutral wire right to the ground, giving strong protection when a fault pops up. In contrast, the TT layout drives its grounding rod into the earth, letting electricians customize the bond where codes call for it. The IT network keeps the whole circuit floating by avoiding any direct earth link, which helps keep pesky fault currents low, especially in labs or hospitals.

Understanding the TN-C, TN-S, and TN-C-S Systems

The TN-C setup fuses the neutral wire and the ground wire into one PEN connection. This can tidy up the installation, yet it forces designers to watch every detail so faults don't spread. In contrast, the TN-S scheme keeps those two lines apart from the start. That separation boosts overall safety and makes it easier to deal with short-circuits. The TN-C-S hybrid strikes a balance by linking the wires together for part of the route and breaking them apart farther down the line. The switch gives installers both freedom and extra protection where it counts.

Choosing the Right Type of Earthing for Your Power System

Picking the right earthing system is more than a quick guess; it needs the right mix of local rules, the way the power lines are set up, and the safety level you want. Think about whether you need solid equipotential bonding and how much punch-proofing against surges and over-voltage is required. Talking it over with a pro who does earthing-system design every day can save a lot of headaches later.

How to Ensure Proper System Earthing in Electrical Installations?

Getting system earthing right starts well before the first wire is laid. Designers must pick quality rods, clamps, and conductors, while installers double-check that joints are tight and corrosion-free. Periodic tests, megger readings, and simple visual scans finally prove that each path to ground is solid and safe.

Best Practices for Earthing System Design

Good earthing design starts with choosing the right setup for your equipment. From there, you space the earth rods or plates so the path back to the ground stays short and the resistance number stays low. Environmental surprises- sandy soil in summer, clay in winter- can change that picture overnight, so you scout the site, pick materials that shrug off corrosion, and double-check the resistance later on.

Maintaining Continuity and Insulation in Wiring

Keeping wires intact and insulated is the first step toward a safe grounding setup. Cheap tape or flimsy connectors won't cut it; switch to sturdier products and check every joint until you're certain nothing will come loose. Good insulation stops stray current in its tracks and lets the entire earthing plan hold together.

Connecting to Earth: Ensuring a Reliable Grounding System

A good grounding system starts with a strong bond to the earth itself, and that bond is only as good as the electrodes and conductors you pick and install. Routine tests and upkeep let you check that bond and fix problems before they become real trouble. Putting grounding first boosts both the safety and the dependability of your entire electrical setup.

Frequently Asked Questions(FAQs)

Q: What is an earthing system, and why is it important for electrical safety?

A: An earthing system, also known as a grounding system, is a network of connections that links electrical installations to the earth to ensure safety. It prevents potential electrical shocks by providing a path for fault currents, such as ground fault currents, to dissipate safely into the earth. This is crucial for protecting both people and equipment from electrical hazards.

Q: What are the different types of earthing systems?

A: The main types of earthing systems include the TT earthing system, TN system, and IT system. Each system has distinct characteristics and is chosen based on specific installation requirements. The TT system relies on a direct connection to earth, while TN systems use a combination of protective earth and neutral conductors. The IT system is isolated from Earth or connected through high impedance.

Q: Can you explain the TN system and its configurations?

A: The TN system is a type of earthing system where the supply neutral is connected to earth at the substation. It has three main configurations: TN-S, TN-C, and TN-C-S. The TN-S system has separate protective (PE) and neutral (N) conductors throughout. The TN-C system combines the neutral and protective functions in a single conductor called the PEN conductor. The TN-C-S system starts as a TN-C system and transitions to a TN-S system at the consumer's premises.

Q: What role does the PE conductor play in a TN-S system?

A: In a TN-S system, the PE conductor, or protective earth conductor, is responsible for maintaining electrical safety by providing a path for earth fault currents. It ensures that any exposed conductive parts of the installation are at the same potential as the earth, preventing potential electrical shocks.

Q: How does the TT earthing system differ from the TN system?

A: The TT earthing system differs from the TN system in that it has a direct connection to earth for each installation. Unlike the TN system, which uses a common connection at the substation, the TT system relies on individual earth electrodes for grounding. This system is often used in rural areas where a reliable connection to a central supply system is not feasible.

Q: Why is the connection to the earth important in electrical installations?

A: Connection to earth is vital in electrical installations as it provides a reference point for the system voltage and a path for fault currents to safely dissipate. This connection helps prevent potential electrical hazards, such as electric shocks and fires, by ensuring that fault currents do not remain within the installation.

Earthing Lightning Protection System Surge Tank(SP-B100)US$ 0.1 - 99MOQ: 50 PiecesYueqing Saip Electric Company Limited5 YRS

Earthing Lightning Protection System Surge Tank(SP-B100)US$ 0.1 - 99MOQ: 50 PiecesYueqing Saip Electric Company Limited5 YRS DC System Earth Ground Fault Detection Tester dc system ground fault detectionUS$ 600 - 1,699MOQ: 1 PieceHuazheng Electric Manufacturing (baoding) Co., Ltd.5 YRS

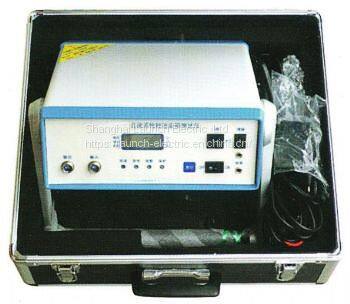

DC System Earth Ground Fault Detection Tester dc system ground fault detectionUS$ 600 - 1,699MOQ: 1 PieceHuazheng Electric Manufacturing (baoding) Co., Ltd.5 YRS SFJ946 DC System Earthing Fault Testing InstrumentNegotiableMOQ: 1 PieceShanghai Launch Electric. Ltd

SFJ946 DC System Earthing Fault Testing InstrumentNegotiableMOQ: 1 PieceShanghai Launch Electric. Ltd Chemical Ground ElectrodeUS$ 3 - 10MOQ: 500 Piecesningbo zhenhai beisuda petrochemical equipment co.,ltd

Chemical Ground ElectrodeUS$ 3 - 10MOQ: 500 Piecesningbo zhenhai beisuda petrochemical equipment co.,ltd Honunity Solar Grounding Lug for solar lightning protectionUS$ 0.42 - 0.65MOQ: 50 UnitsQUANZHOU HONUNITY TECHNOLOGY LTD

Honunity Solar Grounding Lug for solar lightning protectionUS$ 0.42 - 0.65MOQ: 50 UnitsQUANZHOU HONUNITY TECHNOLOGY LTD solar system earthing clipUS$ 0.15 - 0.25MOQ: 1000 PiecesShanghai Frontier Energy Technology Co., Ltd.

solar system earthing clipUS$ 0.15 - 0.25MOQ: 1000 PiecesShanghai Frontier Energy Technology Co., Ltd. Geocell Earth Retention SystemUS$ 0.15 - 1.5MOQ: 5000 Square MetersTaian City Rui Heng Building Materials Co., Ltd.

Geocell Earth Retention SystemUS$ 0.15 - 1.5MOQ: 5000 Square MetersTaian City Rui Heng Building Materials Co., Ltd. Earth rod resistance test for earthing system testingUS$ 1,350 - 1,550MOQ: 1 SetHebei Gaotiejian Testing Instrument Co., Ltd.

Earth rod resistance test for earthing system testingUS$ 1,350 - 1,550MOQ: 1 SetHebei Gaotiejian Testing Instrument Co., Ltd. Static Earth Indicating Systems ESD Grounding SystemUS$ 550 - 600MOQ: 20 SetsQingdao Alptec Safety Equipment Co., Ltd.

Static Earth Indicating Systems ESD Grounding SystemUS$ 550 - 600MOQ: 20 SetsQingdao Alptec Safety Equipment Co., Ltd. Round Shaft Helical Earth Screw Anchor for Solar Mounting SystemUS$ 20 - 30MOQ: 200 PiecesBetter Screw Co.

Round Shaft Helical Earth Screw Anchor for Solar Mounting SystemUS$ 20 - 30MOQ: 200 PiecesBetter Screw Co. PV Panel Mounting System/Grounding System/earthing systemUS$ 0.1 - 0.55MOQ: 10 SetsSunforson Power(Xiamen) Co., Ltd.

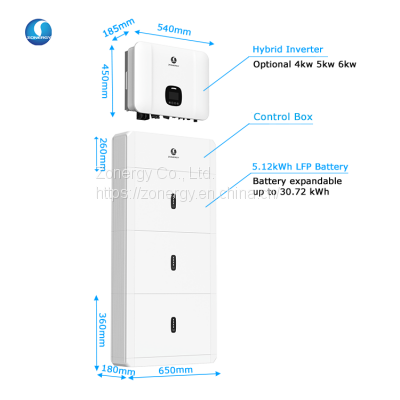

PV Panel Mounting System/Grounding System/earthing systemUS$ 0.1 - 0.55MOQ: 10 SetsSunforson Power(Xiamen) Co., Ltd. Zonergy Wholesale Price 6200W 48V Off On Grid Hybrid Solar Inverter 5Kw With Mppt For Soler Power System HomeUS$ 2082.39 - 8298.60MOQ: 1 PieceZonergy Corporation

Zonergy Wholesale Price 6200W 48V Off On Grid Hybrid Solar Inverter 5Kw With Mppt For Soler Power System HomeUS$ 2082.39 - 8298.60MOQ: 1 PieceZonergy Corporation Earth friendly 1.5kw solar pump systemUS$ 500 - 1,000MOQ: 1 PieceGuangzhou SST Heating Energy Co., Ltd.

Earth friendly 1.5kw solar pump systemUS$ 500 - 1,000MOQ: 1 PieceGuangzhou SST Heating Energy Co., Ltd. Earth Anchors System Ground Screw AnchorUS$ 1 - 2MOQ: 500 PiecesQingdao Hetian Import And Export Co., Ltd.

Earth Anchors System Ground Screw AnchorUS$ 1 - 2MOQ: 500 PiecesQingdao Hetian Import And Export Co., Ltd. google earth gsm car tracking systemUS$ 50 - 130MOQ: 10 PiecesShenzhen CASTEL Wireless Telecommunications Co., Ltd.

google earth gsm car tracking systemUS$ 50 - 130MOQ: 10 PiecesShenzhen CASTEL Wireless Telecommunications Co., Ltd. Q235 earth pile for solar mounting systemUS$ 2 - 18MOQ: 100 PiecesBazhou City Tianda Gas Spring Factory

Q235 earth pile for solar mounting systemUS$ 2 - 18MOQ: 100 PiecesBazhou City Tianda Gas Spring Factory solar system Earth inflatable planet with led lightNegotiableMOQ: 1 PieceGuangzhou Tu Bo Industrial Limited

solar system Earth inflatable planet with led lightNegotiableMOQ: 1 PieceGuangzhou Tu Bo Industrial Limited Buying From China Earth Screw Anchors SystemUS$ 2 - 20MOQ: 100 PiecesQingdao Wangbaoqiang Industry Co., Ltd.

Buying From China Earth Screw Anchors SystemUS$ 2 - 20MOQ: 100 PiecesQingdao Wangbaoqiang Industry Co., Ltd. Solar mounting rack system with earth screwUS$ 3 - 30MOQ: 10 SetsQingdao Wangbaoqiang Industry Co., Ltd.

Solar mounting rack system with earth screwUS$ 3 - 30MOQ: 10 SetsQingdao Wangbaoqiang Industry Co., Ltd. Copper Bonded Earthing Rod For Lightning Protection SystemUS$ 0.1 - 10MOQ: 100 PiecesXinchang Zhongke Electric Co., Ltd.

Copper Bonded Earthing Rod For Lightning Protection SystemUS$ 0.1 - 10MOQ: 100 PiecesXinchang Zhongke Electric Co., Ltd.