construction equipment Insights & Buyer's Guide

Welcome to the wide-open world of construction gear, where fresh ideas bump up against everyday usefulness. If you're stacking concrete into a high-rise or rolling asphalt across a county road, the right machine almost always speeds things up and cuts down on danger. This quick read breaks down the main categories of heavy iron, so you can pick the tools that match your job without guessing. We'll touch on everything from rumbling excavators to nimble compact track loaders and lay out the basics of buying versus renting, no jargon required.

What Are the Different Types of Construction Equipment?

Understanding Excavators and Their Uses

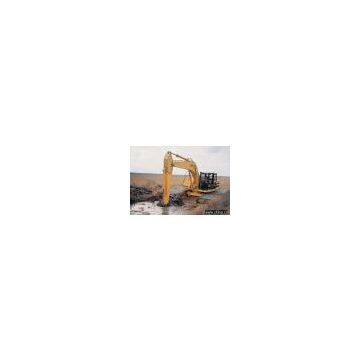

Excavators are the most ubiquitous construction equipment as they are powerful and multi-purpose machines. Such machines contain a bucket or a shearing apparatus and possess a hydraulic arm, are easy to dig trenches or transport materials. Be it an excavation or a demolition site, one can deploy appropriate machines to take care of different processes. Since the attachment rotates in all directions, it provides the operator with the ability to dig and position accurately with resulting in a substantial increase in efficiency. Purchasing a reliable excavator can help minimize the expenses of hiring surplus workers and, as a result, speed up the construction process substantially.

The Role of Loaders and Skid Steer Loaders in Construction

Loaders-propelling buckets, spinning wheels, and a little bit of monster-truck attitude-have become the go-to workhorse for shifting dirt, gravel, or the last sticky heap left at a job site. The family ranges from toy-town compact machines to big-wheeled titans that startle passing motorists. Plenty of crews insist on the skid steer because it can twist into a parking-lot alley and still climb a mini-mountain of demo debris. Pop on a set of forks, swap for a grading bucket, and the same iron chassis suddenly plays road repair, building pad, or cleanup pro with hardly a prayer.

Exploring the Versatility of Compact Track Loaders

Compact track loaders, or CTLs for short, have quietly transformed the way builders work on rough job sites. The continuous rubber tracks spread the machine's weight, so it grips steep ground without tipping and leaves barely a mark on soft sod. Flip on an auger or hitch up a trencher, and the loader is ready to bore holes or slice utility lines within minutes. Because they fit through standard gates yet pack the power of larger machines, CTLs quickly earn their keep-and then some-in any rental yard or contractor fleet.

How to Choose the Right Heavy Equipment for Your Project?

Factors to Consider When Selecting a Crane or Backhoe

Picking the right piece of heavy gear can make or break a job. A big crane shines when the goal is to hoist steel high into the sky. A trusty backhoe, on the other hand, digs up dirt, tracks, and trenches without fuss. To settle on the best fit, check the machine's load limit, boom reach, and how easily it turns on the site. Keep an eye on the bolted-on tools, too. The quicker an attachment matches, the smarter the buyer feels.

Deciding Between a Forklift and a Telehandler

Picking the right machine for lifting stuff around is all about what you're doing. A good forklift slides neatly down warehouse aisles, sliding pallets on and off with hardly a noise. On the other hand, a telehandler stretches its boom far into the air, perfect for grabbing bundles way up on a construction scaffold. Swap in a bucket or a personnel platform, and that same telehandler becomes a whole new tool. Before you rent anything, study your site and jot down the jobs ahead so you don't waste time and cash.

When to Opt for a Bulldozer or a Motor Grader

Bulldozers and motor graders sit at the front of almost every earthmoving project. A good bulldozer can shove huge piles of dirt, rock, or debris like it's no big deal, so crews grab one the minute land needs clearing. The motor grader, meanwhile, works in tiny increments. Its long moldboard turns a lumpy path into a glass-smooth grade in almost no time. Choosing between the two is mostly common sense, heavy pushing points you to the dozer, and slick finish work points you to the grader.

What Maintenance is Required for Heavy Machinery?

Routine Checks for Hydraulic Systems and Compactors

Heavy machinery needs regular TLC if you want it to run right and last a long time. That includes everything hydraulic, as well as the compactors that pound down surfaces. Simple, routine checks let you spot low fluids, cracked hoses, or loose lines before they turn into expensive leaks. Compactors, on the other hand, demand a look at the drums and vibratory gear so the mix settles evenly and no parts wear out too fast. A solid maintenance calendar keeps the gear dependable and keeps surprise breakdowns from ruining your day.

Maintaining Attachments and Keeping Equipment in Top Shape

A construction machine is only as good as the gear you bolt onto it, so the right attachment makes all the difference. A worn bucket or rusty auger can waste time and money if you don't check it first. Grease the pins, wipe away debris, and stash the tools in a dry place to keep corrosion from doing its worst. Jotting service dates in a simple logbook or app allows you to spot trouble early and stick to the schedule.

Preventive Measures for Long-Term Equipment Durability

Preventive maintenance keeps your heavy machinery up and running for many seasons. Think of it as giving your bulldozer a yearly check-up instead of waiting for the engine to quit. Regular oil changes, quick belt inspections, and swapping worn parts early can dodge the really big repair bills. When operators learn the right way to use the equipment- and maybe a few smart safety the machines take less pounding and stay useful.

Frequently Asked Questions(FAQs)

Q: What are the most popular brands of construction equipment for sale?

A: Some of the most popular brands include Caterpillar, John Deere, Komatsu, JCB, and Volvo. These brands offer a wide range of construction machinery, including backhoe loaders, dozers, and wheel loaders, known for their reliability and rugged performance.

Q: What types of compact equipment are available for small construction sites?

A: Compact equipment such as mini excavators, skid steers, and compact track loaders (CTL) is ideal for small construction sites. They offer versatility and are perfect for tasks where larger machines cannot be used.

Q: How do I choose the right wheel loaders for my construction project?

A: When choosing wheel loaders, consider the size of your construction site, the type of material you will be moving, and the loader's lifting capacity. Brands like Caterpillar and John Deere offer various models designed for different needs.

Q: What is the benefit of using telehandlers on a construction site?

A: Telehandlers are versatile machines that can lift and move heavy loads to elevated heights, making them ideal for construction sites. They can be used with various attachments such as forks, buckets, and lifts, providing flexibility for different tasks.

Q: Are there specific machines for asphalt compaction?

A: Yes, machines such as rollers and plate compactors are specifically designed for asphalt compaction. These machines ensure a smooth and even surface, which is crucial for road construction and paving projects.

Q: What is the role of a cold planer in construction?

A: A cold planer is used to remove asphalt or concrete surfaces, typically during road repairs. It grinds the surface to a specified depth, which can then be recycled and reused in new paving projects, making it an essential machine for road maintenance.

Q: Can construction equipment be used in forestry applications?

A: Yes, certain construction equipment, like dozers, articulated trucks, and excavators, can be adapted for forestry applications. These machines are used for tasks such as land clearing, road building, and log handling in forestry operations.

Q: How can I ensure the safety of operators using construction machinery?

A: Ensure that all operators are properly trained and certified to use the machinery. Regular maintenance checks, using machines with safety features like cabs and seat belts, and adhering to safety protocols on the construction site are crucial for operator safety.

High Efficiency Portable construction equipmentUS$ 1 - 10000MOQ: 1 PieceJining Jinlin Machinery Equipment Co., Ltd.

High Efficiency Portable construction equipmentUS$ 1 - 10000MOQ: 1 PieceJining Jinlin Machinery Equipment Co., Ltd. construction equipment - Excavators and Loaders,Excavator Diesel EnginesUS$ 10000 - 92000MOQ: 1 UnitHENAN FOCUS VEHICLES CO.,LTD.

construction equipment - Excavators and Loaders,Excavator Diesel EnginesUS$ 10000 - 92000MOQ: 1 UnitHENAN FOCUS VEHICLES CO.,LTD. Bobcat T320 Rubber Track B450*86*55 for LoaderUS$ 500 - 550MOQ: 2 UnitsShanghai Puyi Industrial Co., Ltd

Bobcat T320 Rubber Track B450*86*55 for LoaderUS$ 500 - 550MOQ: 2 UnitsShanghai Puyi Industrial Co., Ltd 400*74*72 Rubber Track for Excavator UseUS$ 625 - 625MOQ: 2 PiecesSHANGHAI BOOM INTERNATIONAL TRADE CO.,LTD

400*74*72 Rubber Track for Excavator UseUS$ 625 - 625MOQ: 2 PiecesSHANGHAI BOOM INTERNATIONAL TRADE CO.,LTD Nailing machines and equipments for pallets constructionsUS$ 20000 - 50000MOQ: 1 SetZhengzhou Invech Machinery CO. Limited

Nailing machines and equipments for pallets constructionsUS$ 20000 - 50000MOQ: 1 SetZhengzhou Invech Machinery CO. Limited construction equipmentsUS$ 1.65 - 2.5MOQ: 25000 KilogramsNingbo Tuoxing Precision Casting Co., Ltd.

construction equipmentsUS$ 1.65 - 2.5MOQ: 25000 KilogramsNingbo Tuoxing Precision Casting Co., Ltd. construction equipmentUS$ 6,000 - 6,400MOQ: 1 SetWuxi Yuda Plastic Pipe Welding Machinery Factory

construction equipmentUS$ 6,000 - 6,400MOQ: 1 SetWuxi Yuda Plastic Pipe Welding Machinery Factory