co2 laser marking machine Insights & Buyer's Guide

In manufacturing and design, there has been constant advancement in these fields where brands prioritize precision and increased efficiency at work. CO2 laser marking machines are one of the marking machines that CO2 laser systems have to offer which is unrivaled when it comes to accuracy as well as versatility. Through these systems, marking machines like CO2 have been proven to not only enhance productivity but also ensure designs are executed with precision. Be it clear and sturdy markings or complex engravings, CO2 laser systems have dynamic solutions for all. Find out how we can meet your industry demands through innovations powered by CO2 laser.

What is a CO2 Laser Marking Machine?

How a CO2 Laser Works

The function of a CO2 laser marking machine involves producing a nimble laser beam that can effortlessly change the surface of a material. This is done by exciting a compound gas that consists of carbon dioxide gas and a number of other gasses which generates a CO2 laser marking, engraving or cutting beam capable of accurately astounding ranges of material. The yield is based upon focusing the laser towards a very small spot which guarantees bost astonishing scratched intricate designs. This technology is very important in custom and precision reliant industries.

Materials Suitable for Marking with CO2 Lasers

A CO2 laser can engrave and mark on a wide range of materials including wood, acrylic, leather, glass and plastics. They are also good at making fine engravings and even etching on some metals. This makes them usable in different sectors. They also provide a wonderful finish when marking logos, serials numbers or intricate designs because this adaptability is the main reason why a CO2 laser engraver is popular with businesses that wish to process diverse materials.

Choosing CO2 Laser Engraving

Choosing CO2 Laser for engraving purposes provides numerous advantages such as higher precision, speed, and permanent marking of the surface materials that are suggested to you which makes them very durable for scratches. Compared to other methods, CO2 laser engraving is a non-contact process which significantly reduces the chances of damage compared to handling a material physically. Such methods are ideal for fragile or thin materials since their integrity is not altered. Also, the precision offered by engraving allows intricate designs to be depicted with clarity and exceptional detail.

How Does Laser Engraving Compare with Traditional Methods?

Benefits of Laser Marking Compared To Mechanical Engraving

Compared to mechanical engraving methods, laser marking is more advantageous. First, laser engravers have greater precision, which enables more detailed and accurate designs. Moreover, laser marking is a quicker process which can greatly improve production efficiency. The reduction of manual labor with laser marking machines increases the automation of the entire process, enhances labor savings, and reduces human error, thereby leading to reliable and repetitive outputs. In addition, unlike mechanical methods prone to wear over time, laser systems require very little upkeep, unlike other systems that depend on so-called “perpetual motion.” This makes them cost effective in the long term.

Is It Possible To Mark Plastics and Metals With Lasers?

Indeed, laser marking is not only possible but most ideal for both plastic and metal marking. Plastics can easily marked by CO2 lasers through engraving and branding essential for product identification. Furthermore, though CO2 lasers are better for organic components, light etching can also be done on some metals. Heavier metal engraving is better suited with fiber lasers. However, CO2 lasers are still a good fit for industries that process many materials because they work with a wide variety of materials.

What Are The Industrial Uses Of A CO2 Laser Engraver?

CO2 laser engravers have specific uses in industry through the provision of speed, adaptability, flexibility and precision laser cutting which can be further enhanced greatly with computer-aided design programs. These systems are used in the automotive, aerospace, and electronic industries for marking serial numbers, barcodes, and logos to components that require precision and lasting durability. CO2 laser machines can enhance productivity and accuracy, as processes can be automated, which reduces operational downtime. Furthermore, the efficiency of industrial operations is improved. The versatility of these systems enable companies to respond to sophisticated and various manufacturing challenges easily.

What Should You Look for in a Laser Marking Machine?

Features of Laser Marking Systems

While searching for a laser marking machine, attributes like power output, speed, and precision need to be taken into account. A high-quality CO2 laser cutter and engraver should have a reliable laser tube capable of enduring long consistent power output. Moreover, the software compatibility, interfaces, and materials of construction also influence the machine’s versatility and efficiency. The type of laser used and the materials required for the projects along with them will determine whether CO2 or fiber lasers will be used.

What To Look For In CO2 Laser Tubes

Understanding your precise application requirements for the CO2 laser tube is imperative before making a decision. Important aspects to look at are the power level of the tube and its lifespan when regarding cost effectiveness. For some applications that require very fine detail and minimal destruction of the material, a 30W low power tube may do the job. On the contrary, thicker materials that have to be cut from many surfaces at a fast speed require high power tubes. Maintaining these considerations will ensure selection of a tube that achieve operational goals.

Which Is Better: CO2 Or Fiber Laser

With every innovation comes advantages of its own and these two types of lasers do differ because of it. All in all, the preferences of the user stand out the most along with the materials and application needs.CO2 lasers are particularly versatile in creative industries because they can engrave and cut non-metal materials such as wood and acrylic. In contrast, fiber lasers specialize in marking and engraving metal, doing so with greater precision and speed in metal-heavy projects. Considering the most relevant use cases will help you choose the laser system that best meets your requirements and provides the best return on investment.

How to Optimize the Use of a CO2 Laser Cutter and Engraver?

Setting Up Your Desktop CO2 Laser for Best Performance

For best optimization, start with setting up your desktop CO2 laser on a level, stable surface that has adequate vents for fume and debris retrieval. Calibrating the laser beam's angle, cleaning the lens and mirrors, as well as the other components will sustain optimal performance. With the aid of LightBurn software, control over carving and engraving heightens, allowing for precise changes and improved outcomes. Maintaining your system with regular software updates enhances its efficiency and durability.

What is the Ideal Working Area for Laser Cutting?

Ideal working area zones for laser cutting varies with the size and nature of your projects. For high volume tasks, a large zone is flexible as it allows the user to work on multiple small or large pieces at once boosting total output. For carvers and DIY hobbyists, a compact desktop CO2 laser does the job. The pressure posed by projects alongside your workspace factors will settle the ideal working area for your laser cutting and engraving tasks.

Maintenance Tips for Longevity of Your CO2 Laser Machine

Ensuring the best performance for your CO2 laser machine makes routine inspections and maintenance essential. Key practices involve regularly cleaning the laser's tube, mirrors, and lenses to avoid residue build-up that might impair the laser's effectiveness. Accuracy in cutting and engraving is achieved through regular checks for appropriate alignment and calibration. Maintenance of machine components is also critical to investment protection, including timely replacement of faulty parts and observance of operational guidelines provided by the manufacturer. Adoption of these recommendations will enhance the efficiency of the machine and, in turn, extend its lifespan.

Why is Laser Marking Essential in Modern Manufacturing?

Applications of Laser Marking in Various Industries

The applications of laser marking include almost all sectors of modern manufacturing like marking VINs in automotive, marking surgical tools in the medical field and engraving circuit boards in electronics. Creating high contrast marks which are durable and do not deform the material are made effortlessly with laser technology which adds value in numerous sectors. Such applications justify the use of laser systems in modern manufacturing where standards of quality and traceability are very high.

How Does Laser Technology Enhance Product Traceability?

Product traceability is a very important part of modern manufacturing and the use of laser technology greatly improves the efficiency of product traceability. This is done by allowing engravings of unique identifiers including serial numbers and QR codes that are essential in establishing product authenticity and origin. Advanced industrial regulations are much easier to comply with. The assurance of traceability of even the smallest components increases transparency and accountability, which is crucial through the entire lifecycle of the manufactured product.

The Role of Laser Marking in Sustainable Manufacturing

Reducing waste has become a global concern for every sector which lowers carbon emissions and energy consumption, while increasing sustainability of the environment making manufacturing process as eco friendly as possible. Laser marking is one such technology that meets the criteria.

Unlike older methods of marking that need materials and chemicals, laser marking does not consume materials. There is no wear and tear on the machine parts because the non-contact process does not physically touch them, which increases the lifespan of the equipment and reduces the number of replacements needed. Also, laser machines are energy saving, which is good for the environment because it reduces the impact of the manufacturing processes on nature.

Frequently Asked Questions (FAQs)

Q: What is a CO2 laser marker and how does it work?

A: A CO2 laser marker is a type of laser engraving machine that uses carbon dioxide gas to produce a laser beam. It works by focusing this beam onto a surface to engrave or mark it, which is ideal for non-metal materials such as wood, glass, and certain plastics.

Q: What materials can a CO2 laser engraver and cutter process?

A: A CO2 laser engraver and cutter can effectively process materials like wood, acrylic, glass, leather, paper, and some plastics. It is less effective on metals and certain reflective surfaces, for which a fiber laser engraving machine might be more suitable.

Q: Can a desktop CO2 laser engraver be used for engraving and cutting?

A: Yes, a desktop CO2 laser engraver is capable of both engraving and cutting a wide range of non-metal materials. It is a compact solution suitable for small businesses or hobbyists looking for precision and versatility.

Q: What is the significance of laser power in a laser cutting and engraving machine?

A: Laser power, measured in watts, determines the cutting and engraving capabilities of a laser machine. Higher laser power, such as 60W or 130W CO2 laser machines, allows for deeper cuts and faster processing speeds, expanding the range of materials that can be effectively engraved or cut.

Q: How does a CO2 galvo laser differ from traditional laser engravers?

A: A CO2 galvo laser uses a galvanometer system to rapidly direct the laser beam, allowing for high-speed marking and engraving. This setup is particularly beneficial for intricate designs and high-volume production runs, unlike traditional laser engravers which generally operate more slowly.

Q: Are there specific laser engravers for metal?

A: Yes, for metal engraving, a fiber laser engraver or a laser engraver for metal is typically used, as they are designed to handle the reflective surfaces and higher thermal conductivity of metals.

Q: What factors should I consider when choosing a laser cutter and engraver machine?

A: Consider the laser power, the size of the working area, the types of materials you wish to process, and any additional features like a machine with rotary capabilities for cylindrical objects. Brands like Omtech laser or Cloudray laser offer various models to suit different needs.

3D Dynamic co2 laser marking machineUS$ 8000 - 45000MOQ: 1 SetWuhan Tianxingtong Photoelectricity Technology Co., Ltd

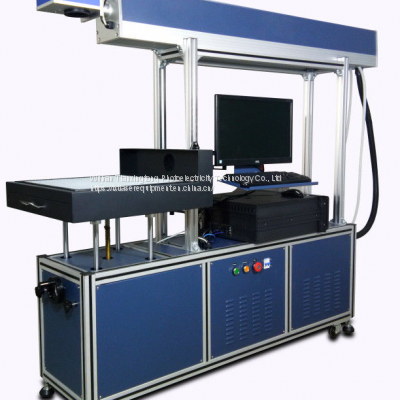

3D Dynamic co2 laser marking machineUS$ 8000 - 45000MOQ: 1 SetWuhan Tianxingtong Photoelectricity Technology Co., Ltd Good quality 30w co2 laser marking machine with CE LM-30FUS$ 7000 - 11000MOQ: 1 SetShandong CCI Trade Co., Ltd.

Good quality 30w co2 laser marking machine with CE LM-30FUS$ 7000 - 11000MOQ: 1 SetShandong CCI Trade Co., Ltd. Nonmetallic Materials Dynamic co2 laser marking machineUS$ 2900 - 3600MOQ: 1 SetPerfect Laser (Wuhan) Co., Ltd.

Nonmetallic Materials Dynamic co2 laser marking machineUS$ 2900 - 3600MOQ: 1 SetPerfect Laser (Wuhan) Co., Ltd. co2 laser marking machineNegotiableMOQ: 1 PieceWuhan Golden Laser Equipments Manufacturing Co., Ltd.

co2 laser marking machineNegotiableMOQ: 1 PieceWuhan Golden Laser Equipments Manufacturing Co., Ltd. co2 laser marking machineUS$ 100 - 100MOQ: 1 SetShandong China Transport Logistics Equipments Co., LTD.

co2 laser marking machineUS$ 100 - 100MOQ: 1 SetShandong China Transport Logistics Equipments Co., LTD. co2 laser marking machineNegotiableMOQ: 1 SetShandong China Coal Mining Equipment & Coal Insdustry

co2 laser marking machineNegotiableMOQ: 1 SetShandong China Coal Mining Equipment & Coal Insdustry co2 laser marking machineUS$ 7,500 - 9,000MOQ: 1 SetBeijing Hongda Boke Scien-Tech Development Co., Ltd.

co2 laser marking machineUS$ 7,500 - 9,000MOQ: 1 SetBeijing Hongda Boke Scien-Tech Development Co., Ltd.