ball valve Insights & Buyer's Guide

Ball valves are essential components in various industries because they provide durability and flow control. These valves can provide shut-off with almost no leakage and are very crucial in systems where flow needs to be controlled with precision, and to prevent leakage. Because of their simple operation and ability to perform well, they have found use in many applications, from oil and gas to water treatment and manufacturing. This article delves into the details of ball valves, their kinds, and applications, as well as recent innovations that have been the driving force behind this industry.

An Introduction to Ball Valves

What Is a Ball Valve?

A ball valve is a kind of control valve that utilizes a spherical disc, or ball, to regulate fluid flow. Fluid passes through when the flow direction is aligned with the hole or port drilled through the ball. Due to their sealing capability against high pressure, ball valves are preferred in applications where a strong seal is needed. Turning the valve handle one-quarter turn either places the ball into the open or closed position, allowing flow or halting flow. This simple mechanism ensures that there is negligible loss of pressure and prevents backflow, maximizing the valve's operational efficiency and reliability.

Working Mechanism of Ball Valves

Ball valves possess a relatively simple mechanism to accomplish flow control through a ball with a central port. When the valve handle is rotated 90 degrees, the ball is rotated as well to either align the port with the flow passage, which allows fluid to pass through, or block the flow passage to prevent the fluid from passing. This quarter-turn operation is what makes the ball valves shut very quickly and efficiently. There are different designs for different flow characteristics:

Full Port Ball Valves: These keep the pressure drop to a minimum by providing a full flow path.

Reduced Port Ball Valves: These have a smaller opening and reduce flow for particular system requirements.

Common Terms Used in Ball Valves

The right terminology used with ball valves helps one select the right kind for any given application. Terms like "floating ball" and "trunnion" refer to the different means of supporting the ball within the valve. Floating ball valves use the fluid pressure to keep the ball against the downstream seat for sealing, while trunnion ball valves provide mechanical anchoring for the ball; they are suited to high-pressure applications. The valve bodies are classified as one-piece, two-piece, and multi-port designs, each giving different advantages, either for ease of maintenance, leakage prevention, or operational function. Familiarity with such terms will assist in ascertaining the right valve design for the particular industrial application.

Types of Ball Valves

Floating Ball Valves

Floating ball valves are among the most popular types of ball valves, widely recognized for their simplicity and excellent sealing capability. In this valve, the ball is not anchored but is pressed downward by the fluid flow toward the downstream seat, allowing it to form a seal. Such a design is highly advantageous in applications where the fluid system demands minimal leakage. Usually, these valves are used where pressures are low, as an increase in fluid pressure aids in generating sufficient sealing force. Designs usually range from one-piece to two-piece, thereby offering the operator easy quarter-turn handle movement for fast opening and closing. Their flexibility and efficiency make them very popular in industrial applications.

Trunnion-Mounted Ball Valves

Trunnion ball valves are specifically designed for high-pressure applications where they provide very stable operation with low torque. Unlike floating ball valves, in a trunnion-mounted ball valve, the ball is anchored by the trunnion bearings, which provide additional support to the ball and prevent excessive movement of the ball. This design is most suitable in high-pressure applications that require the utmost sealing and very little wear. Trunnion-mounted ball valves typically have full-port designs that allow very little pressure drop and provide very high flow efficiency. The indexing action of an actuator will also enable faster and more efficient operation when remote or automatic operation is required. For these reasons, trunnion-mounted ball valves are favorites of the demanding high-pressure oil and gas industry, where high reliability and durability under high pressure are paramount.

Multi-Port Ball Valves

Multi-port ball valves provide flexible flow control since fluids can be directed from multiple ports. They are especially useful in complex piping systems where the fluid is required to be distributed to different lines or redirected without the need for any other valves. These ball valves generally have more than one hole in the ball, making the flow path flexible. These ball valves are made in the form of three-way or four-way types to cater to diversified operational needs. The ease that comes with piping arrangements and reduction in installation costs make the multi-port ball valves an economically viable option for industries that demand flexible flow control. Their versatility, coupled with a very compact design, has made them considerably popular in manufacturing and process industries.

Applications of the Ball Valves

Oil and Gas Industry

In a sector where high-pressure conditions are frequent and shut-off should always be reliable, ball valves play the most important part. These valves control the flow of crude oil, natural gas, or other fluids, thereby assuring operational safety and efficiency. High-pressure ball valves, such as trunnion-mounted types, were typically preferred for their stability and low operating torque in both upstream and downstream applications. The use of full-port ball valves reduces pressure drops, thereby maintaining efficient fluid transfer. Their rugged construction and perfect sealing prevent leakage and backflow that eventually may cause pipeline and process facilities to be compromised.

Water Treatment Plants

They are vital for water treatment plants as they control flow and shut off in different stages with high precision. These valves are subjected to various fluids that may contain suspended solids and are expected to carry out filtration or chemical dosing. Multi-port ball valves provide a great deal of flexibility to redirect flow paths and optimize treatment. Full-port ball valves minimize pressure drop and guarantee adequate water flow and pressure through the system. Coupled with simple quarter-turn operation, ease of maintenance and operation further contribute to overall efficiencies and reliability of water treatment systems.

Manufacturing Uses

Ball valves in manufacturing use assist in the precise flow control and efficiency maintenance of some processes. A ball valve can withstand heavy-duty applications; hence, it is employed in different sectors of the industrial environment. Two-piece ball valves are widely considered the most suitable to install in manufacturing processes because of their ease of maintenance and repair. Furthermore, the installation of actuators may allow automated control, which enhances operational efficiency. Full-bore and reduced port designs serve different flow requirements, so that they can serve various manufacturing environments with ease. By providing reliable shut-offs and minimal leakage, ball valves significantly contribute to product quality and safety, further emphasizing their worth in manufacturing processes.

Maintenance Tips for Ball Valves

Cleaning Procedures

The cleaning of valves is essential to ensure optimum performance and so by applying to their longevity. Almost invariably, high-pressure jurisdictions like oil and gas demand regular valve cleaning. The procedures are as follows:

First, isolate the valve in the system to prevent fluid flow. With the valve in the closed position, proceed with disassembly with special consideration to the valve bodies along with the internals.

Upon thorough cleaning of all components, remove any buildup of debris or contaminants that impede flow control or cause leakage. Cleaning agents should be compatible with valve materials and are especially crucial when working with stainless steel or plastic valves.

Ensuring the ball with the hole is free of any possible obstruction will keep the valve workable, much more so in full-port and reduced-port designs.

Lubrication Techniques

Lubrication is the primary recourse to granting smooth movement to all moving parts of a ball valve, including the valve handle and the ball, while maintaining friction to a minimum. It becomes even more important in high-pressure situations, and the cycle is rather high. The following steps make for an effective lubrication:

The lubricant should be chosen, in view of the media it will be controlling, and the materials composing the valve.

Make sure that the lubricant covers all moving surfaces associated with the valve stem and seats.

This will diminish wearing and tearing and thus extend the service life of the valve. In the case of trunnion-mounted and floating ball valves, make sure that the lubricant is compatible with the particular pressure ratings and operating conditions so as not to cause any impairment to the valve during operation.

Troubleshooting Common Issues

In rare situations, the ball valves may develop issues of leakage, tough operation, or pressure drop. Go for leakage by inspecting the valve bodies and seals for signs of wear or damage, as these are often the points of leakage. In cases where the valve operation is tough, look for some possible debris or corrosion causing a stick to the ball itself. For abuse in pressure drop, making sure that the valve is not half-closed and that the port ball is not scoring the flow path may assist. These problems may be identified and solved at an early stage through the regular inspection and maintenance of ball valves so as not to jeopardize their efficiency and effectiveness in service for all those applications.

Frequently Asked Questions (FAQs)

What are the different ball valve types and their applications?

Ball valves come in various types tailored for specific applications. The most common types include full-port ball valves, standard port ball valves, and trunnion ball valves. Full-port ball valves provide a larger bore size, allowing for maximum flow rate, which is ideal for applications requiring high flow, such as in the oil and gas industries. On the other hand, standard port ball valves have a reduced bore size, which can limit flow but offer a more compact design. Trunnion-mounted ball valves are designed for high-pressure applications and provide a tight seal, making them suitable for valves that use in high-pressure pressure. Understanding the different types ensures you choose the right valve for your piping system.

What is the difference between a full-port valve and a standard-port ball valve?

The primary difference between full-port valves and standard-port ball valves lies in their bore size. A full port valve features a bore that matches the pipeline diameter, facilitating unrestricted flow of liquids, while a standard port valve has a smaller bore, which can result in a pressure drop. Full-port valves are typically used in applications where maximum flow is essential, such as in water supply systems or oil and gas operations. Conversely, standard port valves may be used for throttling applications where flow control is needed, but at a reduced rate. Choosing between these valve types depends on the specific application requirements, including flow rate and pressure considerations.

How does a trunnion ball valve work?

A trunnion ball valve operates using a ball with a hole that pivots around fixed trunnions located at the top and bottom of the ball. This design allows for a full-bore flow path, which minimizes pressure loss and provides a high flow rate. The trunnion-mounted design also enhances the valve’s stability and durability, making it suitable for high-pressure and high-temperature applications. When the valve is open, the flow of liquids passes through the hole in the ball, while a tight seal is created when the valve is closed. Trunnion ball valves are commonly used in oil and gas applications due to their robust construction and ability to maintain flow control under varying pressures.

What are the advantages of using a one-piece ball valve?

One-piece ball valves offer several advantages over other valve designs. They provide a simpler and more robust construction, which can lead to enhanced durability and a longer lifespan. Since the body of the valve is a single piece, there are fewer potential leak points, resulting in a tight seal when the valve is closed. This makes one-piece ball valves particularly effective for applications requiring a high level of reliability, such as in water treatment facilities or chemical processing. Additionally, these valves often allow for easier installation and maintenance, which can reduce downtime and overall operational costs. Their ease of operation further contributes to their popularity in various applications.

What are the typical uses of floating ball valves?

Floating ball valves are primarily used in applications requiring reliable shut-off and flow control. The design features a ball that is not fixed in place but instead "floats" between two seats, allowing it to move slightly and create a tight seal when closed. This characteristic makes floating ball valves ideal for low to medium-pressure applications, such as in the water and wastewater industry. Additionally, they can handle various fluids, including corrosive liquids, due to their robust construction. Floating ball valves are commonly chosen for their simplicity and effectiveness in providing a reliable shut-off, making them suitable for many control applications.

How do ball valves compare to globe valves?

Ball valves and globe valves serve different functions within a piping system, with distinct operational characteristics. Ball valves are designed for quick shut-off and full flow applications, offering a tight seal when closed and minimal pressure drop when open. In contrast, globe valves are primarily used for throttling and flow control, which makes them better suited for applications where precise flow regulation is necessary. While ball valves can be operated manually or automatically, globe valves typically require more effort to adjust the flow rate. The choice between these valve types ultimately depends on the specific application, desired flow characteristics, and ease of operation required for the system.

615112168, Norgren ball valve, G3/4' ThreadUS$ 100MOQ: 1 PieceHunan shanbuzhuanshuizhuan Power Technology co.,Ltd1 YR

615112168, Norgren ball valve, G3/4' ThreadUS$ 100MOQ: 1 PieceHunan shanbuzhuanshuizhuan Power Technology co.,Ltd1 YR Factory Wholesale PVC Compound Granules for ball valveUS$ 850.00 - 920.00MOQ: 1 TonTongxiang Small Boss Special Plastic Products Co.,Ltd.1 YR

Factory Wholesale PVC Compound Granules for ball valveUS$ 850.00 - 920.00MOQ: 1 TonTongxiang Small Boss Special Plastic Products Co.,Ltd.1 YR ball valve Soft Vinyl Pvc Rubber Heat Resistant Handle SleeveUS$ 0.08 - 0.3MOQ: 1 PieceZhongshan MOCAP Industry Co.,LTD1 YR

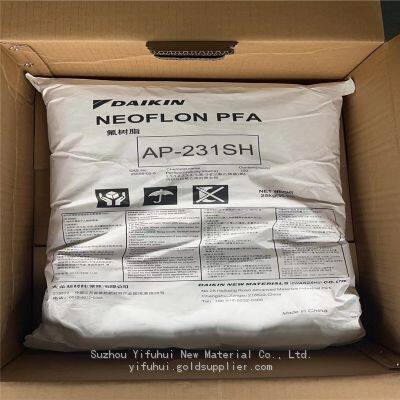

ball valve Soft Vinyl Pvc Rubber Heat Resistant Handle SleeveUS$ 0.08 - 0.3MOQ: 1 PieceZhongshan MOCAP Industry Co.,LTD1 YR PFA for Lined ball valve Butterfly Valve Electric Copper Wire Cable TubeUS$ 60 - 90MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS

PFA for Lined ball valve Butterfly Valve Electric Copper Wire Cable TubeUS$ 60 - 90MOQ: 25 KilogramsSuzhou Yifuhui New Material Co., Ltd.2 YRS Air conditioner ball valve / Refrigeration ball valve / Brass ball valveUS$ 1 - 5MOQ: 300 PiecesNingbo Partsnet Co., Ltd.5 YRS

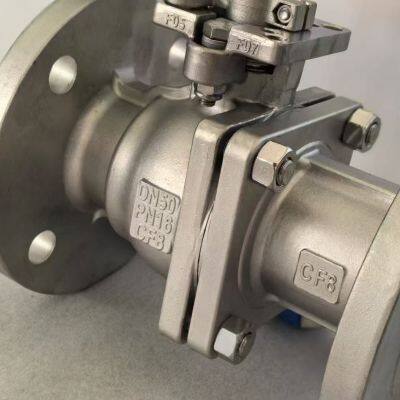

Air conditioner ball valve / Refrigeration ball valve / Brass ball valveUS$ 1 - 5MOQ: 300 PiecesNingbo Partsnet Co., Ltd.5 YRS manual ball valve 3 piece ball valvesUS$ 1 - 20MOQ: 1 PieceXi'an Yunyi Instrument Co., Ltd.5 YRS

manual ball valve 3 piece ball valvesUS$ 1 - 20MOQ: 1 PieceXi'an Yunyi Instrument Co., Ltd.5 YRS carbon steel ball valvesUS$ 5.00 - 15.00MOQ: 10 SetsShanghong Mechanical Equipment Import & Export Co., Ltd.5 YRS

carbon steel ball valvesUS$ 5.00 - 15.00MOQ: 10 SetsShanghong Mechanical Equipment Import & Export Co., Ltd.5 YRS One Piece ball valvesNegotiableMOQ: 1 0Qingdao Launch Foundation International Trading Co., Ltd.5 YRS

One Piece ball valvesNegotiableMOQ: 1 0Qingdao Launch Foundation International Trading Co., Ltd.5 YRS Electric ball valve actuatorUS$ 800 - 2,000MOQ: 1 SetGuangdong Kaidi Energy Technology Co., Ltd.5 YRS

Electric ball valve actuatorUS$ 800 - 2,000MOQ: 1 SetGuangdong Kaidi Energy Technology Co., Ltd.5 YRS JKTL ppr ball valveUS$ 18.56 - 196.58MOQ: 1 PieceHebei Tongli Automatic Control Valve Manufacturing Co., Ltd.5 YRS

JKTL ppr ball valveUS$ 18.56 - 196.58MOQ: 1 PieceHebei Tongli Automatic Control Valve Manufacturing Co., Ltd.5 YRS OEM Manufacturer ball valveUS$ 5 - 10MOQ: 100 PiecesNingbo Yinzhou Miaosen Machinery Co., Ltd.5 YRS

OEM Manufacturer ball valveUS$ 5 - 10MOQ: 100 PiecesNingbo Yinzhou Miaosen Machinery Co., Ltd.5 YRS