air tool Insights & Buyer's Guide

The complete air tool kit has power and productivity features to empower your projects. You are well covered concerning pneumatic tools with us if you are an enthusiast or a professional contractor, because they guarantee reliability and performance. From air compressors to impact wrenches, every air tool needed for every project is available and engineered to precision and power for unmatched versatility.

What is an Air Tool and How Does it Work?

Understanding Pneumatic Tools

Pneumatic tools, or air tools, use compressed air from an air compressor as their power source. This category of tools includes air hammers, grinders, and drills, which deliver a considerable amount of horsepower and torque when used, surpassing the strength provided by electric motors. The air compressor also aids in providing the necessary psi (pounds per square inch) to power the tools, making it suitable for strenuous tasks in the automotive and industrial fields.

Key Components of an Air Tool

Every air tool is composed of several key components that help it function and give it efficiency. An air hose connects to the tool and the air compressor, allowing the flow of compressed air. Secondary parts such as nozzles, dual air chucks, and couplers increase the intended use of these tools. Moreover, the tool’s construction, like a pistol grip, and the ergonomics, along with rpm settings, aid the user in comfort during the operation.

Benefits of Using Air Tools

Compared to electric tools, air tools offer several benefits. They are lighter, easier to maintain due to their reduced moving parts, and provide consistent power. Because of these factors, pneumatic tools are highly reliable, which makes them a favorite among professionals. Tools such as impact wrenches and air ratchets provide high torque and accuracy, making them essential in automotive and construction repairs.

How to Choose the Right Air Compressor for Your Needs?

Types of Air Compressors

Selecting an air compressor impacts how well your air tools perform. Different types of air compressors exist, for example, portable and industrial air compressors, both serving unique purposes. Keep in mind things like horsepower (hp), tank size, and psi so that the air compressor works well with your tools and projects.

Factors to Consider When Selecting an Air Compressor

When picking an air compressor, make sure to analyze your requirements. Think about what types of work you will perform, the needed psi, and if your current tools and accessories will work. Also, take into consideration the air compressor’s portability, especially when moving from one project location to another or around the garage.

Air Compressor Accessories for Enhanced Performance

Boost the efficacy of your air compressor with proper add-ons. Accessories for the compressor, like gauges, hoses, and blow guns, are indispensable for the proper functioning of your air-powered tools. Having confidence in any job is achievable by investing in a professional air tool accessory kit, knowing that they will have all the parts required.

What are the Essential Air Tool Accessories?

Must-Have Compressor Accessories

To get the best results with your air tools, make sure to use the right compressor accessories. For example, air hoses, dual air chucks, and tire gauges are essential for safety and operational efficiency. Proper airflow and pressure management provided by these accessories minimizes wear and tear on your tools, thus increasing their functional longevity.

Understanding Air Ratchet and Impact Wrench

Every air tool kit comes with an air ratchet and an impact wrench; they are crucial parts of the set. In contrast to the more powerful impact wrenches designed for rigorous jobs, the air ratchet works deftly within confined spaces to fasten and unfasten bolts. Knowing what tasks each tool is designed for will enable you to select the right tool for your project.

Using Spray Guns and Fasteners Effectively

For any precision work, whether in construction projects or automotive, spray guns and fasteners are indispensable. Carefully designed spray guns make it easier to apply paint and coatings uniformly, while fasteners provide secure mechanical connections. The quality and efficiency of any work will improve significantly if these tools are mastered.

Frequently Asked Questions(FAQs)

Q: What is included in the comprehensive air tool kit?

A: Our comprehensive air tool kit includes a selection of pneumatic tools such as an air impact wrench, die grinder, ratchet wrench, and a 50-piece air socket set. It also features air accessories like a chisel, cutting tools, and a durable carrying cart for easy transport.

Q: How can I ensure the durability of my air tools?

A: To ensure the durability of your air tools, regularly check for wear and tear, use appropriate grease and lubricants, and store them in a dry, safe place. Always follow the manufacturer's maintenance instructions for each tool.

Q: Can the air tool kit be customized?

A: Yes, the air tool kit can be customized to suit specific project needs. You can add or remove tools and air accessories to create a tailored selection of pneumatic tools that best fits your requirements.

Q: What makes the air impact wrench in this kit unique?

A: The air impact wrench in this kit is known for its lightweight and ergonomic design, making it easy to handle. It features a high bpm rate for efficient performance and a reversible function for added versatility.

Q: Are there any safety tips for using cutting tools in the kit?

A: When using cutting tools, ensure they are securely attached and in good condition. Always wear appropriate safety gear, work in a well-ventilated area, and follow the tool's operational guidelines to prevent injuries.

Q: How can I maintain the efficiency of my air compressor tool?

A: To maintain the efficiency of your air compressor tool, regularly check and replace air filters, monitor the oil levels, and ensure all connections are secure. Performing routine maintenance checks will prolong the life of your compressor.

air tool lubricant kobe air tools air tool suppliesUS$ 1 - 10MOQ: 10 UnitsNingmao Hydraulic Pneumatic Components Factory5 YRS

air tool lubricant kobe air tools air tool suppliesUS$ 1 - 10MOQ: 10 UnitsNingmao Hydraulic Pneumatic Components Factory5 YRS Tagore TCX003 pneumatic air toolsUS$ 1 - 30MOQ: 2000 PiecesNingbo Tagore Machinery Co., Ltd.5 YRS

Tagore TCX003 pneumatic air toolsUS$ 1 - 30MOQ: 2000 PiecesNingbo Tagore Machinery Co., Ltd.5 YRS Blow molded portable plastic air tool casesUS$ 1 - 4MOQ: 500 PiecesYuyao Ideal Auto Part Co., Ltd.5 YRS

Blow molded portable plastic air tool casesUS$ 1 - 4MOQ: 500 PiecesYuyao Ideal Auto Part Co., Ltd.5 YRS air tools Color Corrugated Packing BoxUS$ 0.25 - 1.32MOQ: 3000 PiecesShanghai Forest Packing Co., Ltd.5 YRS

air tools Color Corrugated Packing BoxUS$ 0.25 - 1.32MOQ: 3000 PiecesShanghai Forest Packing Co., Ltd.5 YRS air boby saw /high speed air saw/air toolsNegotiableMOQ: 10 PiecesDongguan KangMingJian Tool Co., Ltd.5 YRS

air boby saw /high speed air saw/air toolsNegotiableMOQ: 10 PiecesDongguan KangMingJian Tool Co., Ltd.5 YRS 12/19 Needles Air Pneumatic air tools angle grinderUS$ 22.3 - 36.36MOQ: 100 PiecesDongguan Century Hardware Tools S & T Co., Ltd.5 YRS

12/19 Needles Air Pneumatic air tools angle grinderUS$ 22.3 - 36.36MOQ: 100 PiecesDongguan Century Hardware Tools S & T Co., Ltd.5 YRS CALIBRE air tool 5" Composite Body Air Palm SanderNegotiableMOQ: 100 PiecesPROJEN INDUSTRIAL COMPANY LTD.5 YRS

CALIBRE air tool 5" Composite Body Air Palm SanderNegotiableMOQ: 100 PiecesPROJEN INDUSTRIAL COMPANY LTD.5 YRS China OEM competitive price metal air tools spare partsUS$ 0.01 - 100MOQ: 50 PiecesShenzhen Hafond Technology Co., Ltd.5 YRS

China OEM competitive price metal air tools spare partsUS$ 0.01 - 100MOQ: 50 PiecesShenzhen Hafond Technology Co., Ltd.5 YRS OEM/ODM steel air tool parts / needle bar bushingUS$ 0.1 - 10MOQ: 500 PiecesQingdao Tianluli Industrial Co., Ltd.5 YRS

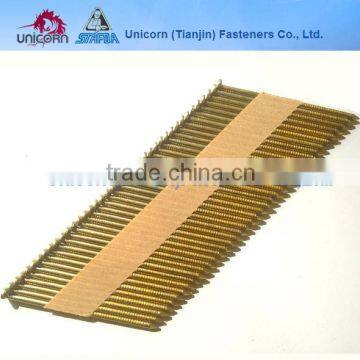

OEM/ODM steel air tool parts / needle bar bushingUS$ 0.1 - 10MOQ: 500 PiecesQingdao Tianluli Industrial Co., Ltd.5 YRS clipped D head paper collated air tool nailUS$ 10 - 20MOQ: 100 CartonsUnicorn (Tianjin) Fasteners Co., Ltd.5 YRS

clipped D head paper collated air tool nailUS$ 10 - 20MOQ: 100 CartonsUnicorn (Tianjin) Fasteners Co., Ltd.5 YRS Rotomolded air blower blower fan,power toolsUS$ 20 - 200MOQ: 1 SetShanghai Chunxu Mould Industrial Co., Ltd.5 YRS

Rotomolded air blower blower fan,power toolsUS$ 20 - 200MOQ: 1 SetShanghai Chunxu Mould Industrial Co., Ltd.5 YRS Professional air brush pump nail tools for salonUS$ 55.3 - 59.4MOQ: 3 PiecesZhejiang Newair Art Co., Ltd.5 YRS

Professional air brush pump nail tools for salonUS$ 55.3 - 59.4MOQ: 3 PiecesZhejiang Newair Art Co., Ltd.5 YRS grease injector automotive air conditioning toolsUS$ 45 - 350MOQ: 1 PieceNanjing Haoli Hydraulic Equipment Co., Ltd.5 YRS

grease injector automotive air conditioning toolsUS$ 45 - 350MOQ: 1 PieceNanjing Haoli Hydraulic Equipment Co., Ltd.5 YRS Machine Tool Exhaust Air Filter with HEPA EquipmentNegotiableMOQ: 5 SetsKlean Environmental Technology (Foshan) Co., Ltd.5 YRS

Machine Tool Exhaust Air Filter with HEPA EquipmentNegotiableMOQ: 5 SetsKlean Environmental Technology (Foshan) Co., Ltd.5 YRS Plastic Auto Air Fliter Mould ToolUS$ 1,000 - 10,000MOQ: 1 SetXiamen Xin Shi Wei Precision Mould Co., Ltd.5 YRS

Plastic Auto Air Fliter Mould ToolUS$ 1,000 - 10,000MOQ: 1 SetXiamen Xin Shi Wei Precision Mould Co., Ltd.5 YRS Y20 air-operated rock drilling toolUS$ 1 - 1,000MOQ: 1 SetXiamen Bestlink Factory Co., Ltd.5 YRS

Y20 air-operated rock drilling toolUS$ 1 - 1,000MOQ: 1 SetXiamen Bestlink Factory Co., Ltd.5 YRS Motorcycle special tools AIR VALVE PULLERNegotiableMOQ: 1000 PiecesNingbo Yinzhou Tengda Daily Hardware Factory5 YRS

Motorcycle special tools AIR VALVE PULLERNegotiableMOQ: 1000 PiecesNingbo Yinzhou Tengda Daily Hardware Factory5 YRS WILITA Auto Air Conditioning Tools Cleaner SprayUS$ 1.5 - 1.88MOQ: 768 PiecesTAI JEOU POLYMER CHEMICAL CO., LTD.5 YRS

WILITA Auto Air Conditioning Tools Cleaner SprayUS$ 1.5 - 1.88MOQ: 768 PiecesTAI JEOU POLYMER CHEMICAL CO., LTD.5 YRS Professional air conditioner hand tools kitUS$ 50 - 80MOQ: 500 SetsHangzhou Pangong Tool Co., Ltd.5 YRS

Professional air conditioner hand tools kitUS$ 50 - 80MOQ: 500 SetsHangzhou Pangong Tool Co., Ltd.5 YRS professional tool Air Filled Pressure Gauge with CENegotiableMOQ: 1 PieceTaian Haiyu Machinery Co., Ltd.5 YRS

professional tool Air Filled Pressure Gauge with CENegotiableMOQ: 1 PieceTaian Haiyu Machinery Co., Ltd.5 YRS Air Coil Nailer in Tools CNR45-HK213NegotiableMOQ: 50 PiecesGuangde Baolin Technology Co., Ltd.5 YRS

Air Coil Nailer in Tools CNR45-HK213NegotiableMOQ: 50 PiecesGuangde Baolin Technology Co., Ltd.5 YRS air conditioner back cover stamping toolsUS$ 1,000 - 100,000MOQ: 1 PieceDongguan Jiacai Hardware Co., Ltd.5 YRS

air conditioner back cover stamping toolsUS$ 1,000 - 100,000MOQ: 1 PieceDongguan Jiacai Hardware Co., Ltd.5 YRS Hardware Tools Cleaning Air Blower Dry System With Air KnifeUS$ 699 - 699MOQ: 1Luomei Electric Technik Co., Ltd.5 YRS

Hardware Tools Cleaning Air Blower Dry System With Air KnifeUS$ 699 - 699MOQ: 1Luomei Electric Technik Co., Ltd.5 YRS Garden Tool air blower,manual air blower,tube blowerUS$ 0.59 - 1.45MOQ: 500 PiecesZhangjiagang City Tianlun Import And Export Trade Co., Ltd.5 YRS

Garden Tool air blower,manual air blower,tube blowerUS$ 0.59 - 1.45MOQ: 500 PiecesZhangjiagang City Tianlun Import And Export Trade Co., Ltd.5 YRS Hydraulic car lifting Air Jack 50Ton and 100Ton Jack Truck ToolsNegotiableMOQ: 100 PiecesLinyi Sinosin Tools Co.,Ltd5 YRS

Hydraulic car lifting Air Jack 50Ton and 100Ton Jack Truck ToolsNegotiableMOQ: 100 PiecesLinyi Sinosin Tools Co.,Ltd5 YRS