Home > Products > Titanium Alloy > Precision Titanium Alloy Bar GR5/GR2 Medical-Grade for Surgical Tools Factory Quality Control Assured

Precision Titanium Alloy Bar GR5/GR2 Medical-Grade for Surgical Tools Factory Quality Control Assured

- Shanghai

- T/T L/C

- 1 days

You May Like

-

GR3/GR7 Forged Titanium Bar Heavy-Duty for Industrial Pressure Vessels Professional Factory Production

-

Rolled Titanium Bar GR12/GR2 Petrochemical-Grade for Pipelines Corrosion-Resistant Factory Direct Supply

-

Gr1 Titanium Bars (Commercial Pure) – High Corrosion Resistance, Annealed/Hot Rolled – Factory Direct Supply

-

Gr2 Pure Titanium Rods – ASTM B348 Certified, Excellent Formability – Custom Cut to Length, Quick Delivery

-

Gr5 Titanium Alloy Bars (Ti-6Al-4V) – Aerospace-Grade Strength, Heat Treated – AMS 4928 Compliant, In-Stock

-

Gr7 Titanium-Palladium Bars (Ti-Pd Alloy) – Superior Corrosion Resistance in Sea Water/Chemicals – Mill Finish or Polished

Product Details

| Surface Treatment | Other, Bright rod | Shape | Bar | |

| Color | Silver | Material | Other, Titanium |

Product Description

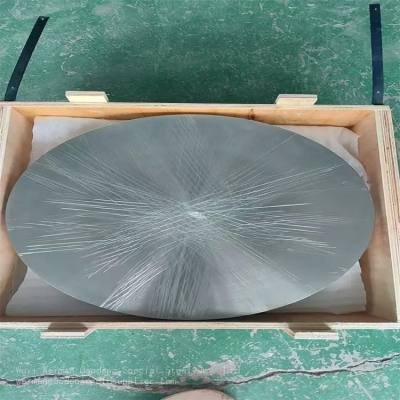

Precision Titanium Alloy Bar GR5/GR2 for Surgical Tools: Factory Quality Control Assured

1. Product Overview

Our Precision Titanium Alloy Bar in GR5/GR2 grades is specifically designed for surgical tools, offering a high - quality solution for the medical industry. Titanium is well - known for its exceptional properties, and these bars are no exception. The GR5 grade, also known as Ti - 6Al - 4V, is a widely used titanium alloy due to its excellent strength - to - weight ratio, corrosion resistance, and biocompatibility. The GR2 grade, on the other hand, is commercially pure titanium, which is highly ductile and has good formability.

2. Material and Surface Treatment

- Material: The bars are made from high - quality titanium. The GR5 alloy contains 6% aluminum and 4% vanadium, which enhances its mechanical properties. The GR2 is composed of commercially pure titanium, ensuring high chemical purity and excellent corrosion resistance, especially in the harsh environment of the human body.

- Surface Treatment: These bars have a bright rod surface treatment. This not only gives them an aesthetically pleasing silver color but also provides a smooth finish. The smooth surface is crucial for surgical tools as it reduces the risk of tissue damage during surgical procedures and makes the tools easier to clean and sterilize.

3. Shape and Dimensions

The shape of the product is a bar, which is a standard and versatile form for manufacturing surgical tools. The bars can be cut and machined into various shapes and sizes according to the specific requirements of different surgical instruments. Our factory has the capability to provide custom - cutting services for these bars. We can handle pipes with an outer diameter (OD) ranging from 20 - 1200mm and plates with a maximum thickness of 120mm. This flexibility allows us to meet the diverse needs of our international customers in the medical field.

4. Quality Control and Certification

- Factory Quality Control: Our factory has a strict quality control system in place. We start from the selection of raw materials, ensuring that only the highest - quality titanium is used. During the manufacturing process, we conduct multiple inspections at different stages. For example, we use advanced Non - Destructive Testing (NDT) services. Ultrasonic Testing (UT) to EN 10228 - 3 is performed to detect internal defects as small as 0.5mm. Magnetic Particle Testing (MT) is used to check for surface cracks, and this testing is certified by SGS and BV.

- Certifications: We ensure that our products comply with international standards. For medical - grade titanium, our GR5 and GR2 bars meet ASTM F136 standards. This certification is a guarantee of the quality and safety of our products for use in surgical tools. Our company also holds ISO 9001:2015, API 5L, and EU PED certifications, which further demonstrate our commitment to quality and compliance.

5. Application in Surgical Tools

These titanium alloy bars are ideal for a wide range of surgical tools. Due to their biocompatibility, they can be used in tools that come into direct contact with the human body, such as scalpels, forceps, and retractors. The high strength - to - weight ratio of the GR5 grade makes it suitable for tools that need to withstand high stress during surgical operations. The ductility of the GR2 grade allows for the manufacturing of tools with complex shapes, such as curved forceps or fine - tipped instruments.

6. Company Background and Support

Our company, established in 2017, has evolved from an R & D - focused startup to a global special steel solution provider. We have a team of experts, including a CEO with over 20 years of experience in the special steel industry and a Chief Metallurgist with a PhD from Tsinghua University. Our technical staff consists of 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring high - quality production and processing of our titanium alloy bars. We also offer rapid logistics. With strategically located warehouses in Wuxi, we can ensure 48 - hour delivery to major Chinese ports. This means that our international customers can receive their orders in a timely manner, reducing production delays and ensuring a smooth supply chain for their surgical tool manufacturing.

In conclusion, our Precision Titanium Alloy Bar GR5/GR2 for surgical tools is a high - quality product with strict quality control, excellent material properties, and strong company support. It is a reliable choice for international buyers in the medical industry.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Gr12 Low-Alloy Titanium Bars – High Temperature Stability (≤500°C), Weldable – For Heat Exchangers & Petrochemical Equipment

-

Titanium Grade 1 Plate - ASTM B265 Certified, Mill Finish, Custom Cut to Size

-

Titanium Grade 2 Plate - Annealed Condition, ISO 9001:2015 Certified, Ready to Ship

-

Titanium Grade 5 Plate (Ti-6Al-4V) - High Strength, Aerospace Grade, CNC Machining Available

-

Titanium Grade 7 Plate (Ti-Pd Alloy) - Corrosion Resistant, Medical-Grade, Polished Surface

-

Titanium Grade 12 Plate (Ti-0.3Mo-0.8Ni) - Excellent Weldability, Industrial Grade, Mill Test Certificates

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar Stock

-

ASME B865 Compliant N05500 Bar Stock | Marine-Grade Corrosion-Resistant Monel K-500 Alloy Bars

-

ASTM B166 Compliant Inconel 600 Bar Stock | High-Temperature & Oxidation-Resistant Nickel-Chromium Bars

-

ASME SB-166 Certified N06600 Round Bar | Heat-Resistant Inconel 600 Alloy Bars for Industrial Use

-

ASTM B446 Compliant Inconel 625 Superalloy Bar | High-Strength Corrosion-Resistant Bar Stock

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy Bars

-

ASTM B637 Compliant Inconel 718 Premium Round Bar | High-Temperature Strength & Fatigue-Resistant Bars

-

ASME SB-637 Certified N07718 Round Bar | Creep-Resistant Machinable Inconel 718 Alloy Bars

-

ASTM A312 TP317L Seamless Stainless Steel Tubes | High Pitting Corrosion Resistance for Chemical Industry

-

ASTM A312 TP310S Seamless Stainless Steel Tubes | 1200℃ High-Temperature Oxidation Resistance for Furnace Applications

-

ASTM A312 TP309S Seamless Stainless Steel Tubes | Carburization-Resistant for High-Temperature Furnace Systems

-

ASTM A312 TP347H Seamless Stainless Steel Tubes | Niobium-Stabilized for High-Temperature Strength in Power Plants

-

ASTM A312 904L Seamless Stainless Steel Tubes | High Molybdenum-Nickel for Severe Corrosion Environments

-

ASTM A312 N08904 Seamless Stainless Steel Tubes | UNS N08904 High-Performance for Harsh Chemical Media

-

Cut to Length Alloy 36 Steel Plate UNS K93603 Invar 36 Corrosion Resisting

-

Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy Components

-

Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy Forgings

-

Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy Parts

Popular Searches

- iron oxide

- square bar

- round rod bar

- titanium alloy

- peeling machine

- mountain bike

- bicycle frame

- titanium material

- titanium plate

- golf cart

- seamless steel pipe

- nickel rod

- titanium foil

- titanium wire

- titanium rod

- titanium metal

- titanium alloy round bar

- titanium rod bar

- flat wire bar

- golf set

- carbide round bar

- gr5 titanium bar

- cold rolled bar

- titanium round rod

- titanium alloy

- titanium material

- titanium plate

- titanium tube

- titanium bar

- nickel rod

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Alloy > Titanium Alloy

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile