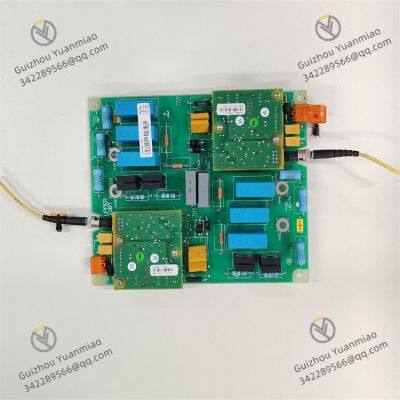

Product Description

As a meticulously designed industrial communication module, ABB DYTP123A 61430001 - TW has emerged prominently in numerous industrial scenarios with its excellent performance, rich functions, and wide applicability, providing solid support for building an intelligent and integrated industrial environment.

I. Technical Specifications

(1) Electrical Characteristics

Power Supply Adaptability: This module is compatible with a power supply voltage of 24 V DC (±20%). This common and stable DC voltage input enables it to seamlessly interface with the vast majority of industrial power supply systems available on the market. Whether in conventional industrial scenarios with stable power supply or in special production environments with complex and variable power conditions, DYTP123A 61430001 - TW can ensure its reliable operation by virtue of its stable power supply adaptability. It greatly reduces the potential risk of failures caused by voltage adaptation issues and provides a reliable power guarantee for the continuity of industrial communication.

Low-Power Design: While operating efficiently, DYTP123A 61430001 - TW maintains a low power consumption level, with a power consumption of only 5 W. This energy-saving feature not only helps reduce the operating cost of individual devices but also, when a large number of such modules are applied in large-scale industrial systems, can significantly reduce the energy consumption of the entire industrial system from a macro perspective. It highly aligns with the globally advocated concept of green and energy-efficient industrial development and effectively promotes the efficient utilization of energy.

(2) Physical Specifications

Compact Size Design: The external dimensions of DYTP123A 61430001 - TW are compact and reasonable, measuring 100 mm x 160 mm x 40 mm. This size specification endows it with high flexibility during installation. It can easily find a suitable installation position whether inside a control cabinet with limited space and a compact layout or in various industrial equipment with strict requirements on device installation dimensions. Its compact structural design is of great significance for optimizing the overall layout of the industrial system and enhancing the convenience of system integration.

Advantages of Lightweight Feature: The entire module weighs only 0.17 kg, and its lightweight feature brings many conveniences to installation and maintenance personnel. During the equipment installation phase, it significantly reduces the labor intensity of handling and installation; in the subsequent equipment maintenance process, if the module position needs to be frequently replaced or adjusted, its lightweight feature can fully demonstrate its advantages, effectively improving the efficiency of equipment maintenance and greatly shortening the production interruption time caused by equipment maintenance.

(3) Support for Communication Protocols

Multi-Protocol "All-Rounder": DYTP123A 61430001 - TW supports a variety of mainstream industrial communication protocols and can be called an "all-rounder" in the field of industrial communication. These include PROFIBUS DP, a fieldbus protocol widely used in the industrial automation field, which can achieve high-speed and reliable data transmission and is suitable for industrial control scenarios with high real-time requirements; the Modbus RTU/TCP protocol, which has strong compatibility and is supported by many third-party devices, enabling DYTP123A 61430001 - TW to conduct efficient data interaction with industrial equipment of different brands and types, greatly expanding the communication range; in addition, it also supports the Ethernet/IP protocol, which is based on Ethernet technology and provides a convenient networked communication method for industrial equipment, facilitating remote monitoring, centralized management, and collaborative work with other systems. By supporting these rich communication protocols, DYTP123A 61430001 - TW can fully meet the needs for communication diversity and compatibility in different industrial application scenarios, laying a solid foundation for building a complex industrial automation communication network.

II. Functional Characteristics

(1) Dual-Channel Redundancy Design

High Reliability Guarantee: Some models of DYTP123A 61430001 - TW innovatively adopt a dual-channel redundancy design. This design is like providing "double insurance" for the communication system. In normal working conditions, the dual channels operate simultaneously, sharing the data transmission task to ensure communication efficiency. Once one of the channels fails, the system can quickly and automatically switch to the other normal channel, continuing to maintain a stable communication connection and ensuring that the industrial production process is not affected. This dual-channel redundancy design significantly improves the reliability and fault tolerance of the system, and is of vital significance for industrial scenarios with extremely high requirements for production continuity, such as the petrochemical and power energy industries. It can effectively reduce the risk of production interruption caused by communication failures and ensure the normal production and operation of enterprises.

(2) Protocol Conversion Function

Communication "Translator": DYTP123A 61430001 - TW has a powerful protocol conversion function, and it is like a "translator" proficient in multiple languages, capable of quickly and accurately converting between different industrial communication protocols. In the actual industrial production environment, there are often various brands and types of equipment, each of which may adopt different communication protocols. The protocol conversion function of DYTP123A 61430001 - TW enables barrier-free communication between these devices, effectively solving the problem of equipment interconnection caused by protocol incompatibility, ensuring the compatibility and integration of the entire industrial automation system, and improving the overall operating efficiency of the system.

III. Application Fields

(1) Manufacturing Factories

Assistance in Production Optimization: In the production lines of manufacturing factories, DYTP123A 61430001 - TW plays a key role in equipment control and process optimization. It can connect various equipment on the production line, such as robots, machine tools, conveyor belts, etc., to realize data sharing and collaborative work between equipment. By real-time collecting and analyzing various data in the production process, such as equipment operating status, product quality data, production progress, etc., DYTP123A 61430001 - TW can provide accurate decision-making basis for production managers, helping them adjust production strategies in a timely manner, optimize production processes, and improve production efficiency and product quality. For example, in an automobile manufacturing factory, DYTP123A 61430001 - TW can connect various equipment on the automobile assembly line into an organic whole, realizing the precise delivery of auto parts, the accurate operation of robots, and the efficient and coordinated operation of the production line, thereby ensuring the production quality and speed of automobiles.

(2) Process Control Systems

Precise Control of Parameters: In process control systems, DYTP123A 61430001 - TW is used for real-time monitoring and precise control of various parameters in the production process. Whether it is parameters such as temperature, pressure, and flow in chemical production, or parameters such as liquid level, concentration, and pH value in food processing, DYTP123A 61430001 - TW can realize accurate collection and rapid response control of these parameters through connection with various sensors and actuators. It can automatically adjust various operations in the production process according to preset process requirements, such as the opening degree of valves, the rotation speed of pumps, the power of heating or cooling equipment, etc., ensuring that the production process is always in the best state, improving the consistency and stability of products, and reducing energy consumption and production costs at the same time. Taking an oil refinery as an example, DYTP123A 61430001 - TW can real-time monitor the operating parameters of key equipment such as crude oil distillation towers and catalytic cracking units, and automatically control the operation of related equipment according to these parameters, ensuring the safety, stability, and efficiency of the oil refining process.

(3) Motion Control Systems

Robot Motion Coordination: In motion control systems, DYTP123A 61430001 - TW plays an indispensable role in controlling the movement and coordinated operation of robots. It can accurately transmit the motion instructions issued by the upper control system to each joint driver of the robot, and at the same time, real-time collect feedback information such as the position, speed, and acceleration of the robot, realizing precise closed-loop control of the robot's motion. Through communication and collaboration with other equipment, DYTP123A 61430001 - TW can also coordinate the actions of multiple robots, enabling them to collaboratively complete various tasks in complex working environments. For example, in a logistics warehouse center, multiple robots can efficiently complete the handling, sorting, and storage of goods under the communication coordination of DYTP123A 61430001 - TW; in an electronic manufacturing workshop, robots can accurately complete fine operations such as mounting and welding of electronic components under its control, improving production efficiency and product quality.

(4) Data Acquisition Systems

Data Aggregation and Transmission: In data acquisition systems, DYTP123A 61430001 - TW acts as a key hub for data aggregation and transmission. It can connect various sensors distributed in industrial sites, such as temperature sensors, pressure sensors, flow sensors, vibration sensors, etc., quickly and accurately collect and sort out the massive industrial data collected by these sensors, and transmit the data to the upper data processing system or cloud platform through its supported communication protocols. During data transmission, DYTP123A 61430001 - TW can conduct preliminary screening, filtering, and preprocessing of data, removing noise data and invalid data, and improving the quality and availability of data. These collected and processed data can provide rich data support for enterprise production decisions, equipment maintenance, quality monitoring, etc., helping enterprises achieve intelligent management and optimized operation. For example, in large industrial parks, DYTP123A 61430001 - TW can centrally collect sensor data distributed in various corners and transmit it to the park's monitoring center, providing a comprehensive data basis for the park's energy management, environmental monitoring, equipment operation status evaluation, etc.

GE IS2020RKPSG3A Power Supply Module

GE F650BABF1G0HI Digital Bay Controller

GE PMC-0247RC-282000 350-93750247-282000F RoHS Serial ATA

GE V7768-320000 3509301007768-320000B Single Board Computer

GE VMIVME4150 Analog Output Board

GE VMIVME2170A ptically Coupled Digital Output board

GE VMIVME1150 Optically Coupled Digital Input Board

GE VMIVME5576 Each Reflective Memory Board

GE VMIVME7698 Single-Board Computer

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4 Machine Protection Card

GE WES13-3 Control Mainboard Module

GE WES5120 5120-1506 power module

Vibro-meter 200-510-070-113 200-510-111-034 VM600 MPC4 Machinery Protection Card

GE WES5302-150 Field controller master unit

GE WES5302-111 Field controller master unit

Vibro-meter 200-510-071-113 200-510-111-034 VM600 MPC4 Machinery Protection Card

Vibro-meter 200-560-000-016 200-560-101-015 VM600 IOC4T Input/Output Card

GE WESCOM D200 VME System Framework

Vibro-meter 200-560-000-018 200-560-101-015 VM600 IOC4T Input/Output Card

GE D20 EME Ethernet/Memory Board D20EME

Vibro-meter 200-560-000-113 200-560-101-017 VM600 IOC4T Input/Output Card

Vibro-meter 200-566-000-012 200-566-101-012 VM600 IOCN Interface Module

GE WES5123-2600 Field controller master unit

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Monitoring Module

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.