Home > Products > non-destructive testing equipment > Ultrasonic device for pile integrity testing in construction Crack detection equipment for concrete using ultrasonic

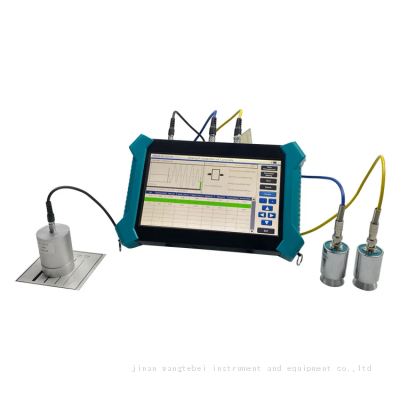

Ultrasonic device for pile integrity testing in construction Crack detection equipment for concrete using ultrasonic

- qingdao,shanghai, tianjin

- T/T L/C PayPal D/P Western Union Other

- 7 days

You May Like

-

U910 concrete NDT ultrasonic detector U960 pile foundation integrity ultrasonic system U930 non-metal flaw detector for concrete bridges and tunnels

-

U950 ultrasonic detector for dam or tunnel inspection U920 ultrasonic system for concrete internal damage

-

Non-destructive ultrasonic crack detection device for concrete U910 Handheld ultrasonic detector for pile integrity testing U960

-

Portable ultrasonic flaw detector for concrete structures U930 Digital ultrasonic detector for measuring concrete strength U950

-

ultrasonic equipment for detecting cracks in concrete U920 Concrete NDT ultrasonic flaw detector U960 with crack width analysis

-

High-precision ultrasonic concrete defect detector U910

Product Description

Overview of use:

Structural concrete compressive strength, crack depth, crack width and defect detection; ultrasonic transmission method to detect the integrity of foundation pile and continuous wall; set pile, ultrasonic rebound comprehensive method strength measurement, lack of measurement, crack sounding and width measurement In one. Geological exploration, rock integrity, weathering evaluation test; mechanical properties of non-metallic materials such as rock mass and concrete.

Features:

With perfect functions, stable performance and high cost performance, it is the best choice for users with diverse needs such as teaching and research.

Semi-transparent, high-brightness, TFT color LCD screen, clearer in the sun;

Wifi connection slit width function;

Double injection molding, waterproof, anti-drop design, protection grade IP65;

Applicable standards:

Ultrasonic Testing of Concrete Defects - CECS 21:000

Technical Specification for Ultrasonic Rebound Comprehensive Method for Testing Concrete Strength-CECS 02:2005

"Code for Testing Concrete Strength of Railway Engineering Structures"-TB 10426-2004

Technical Regulations for Concrete Structure Detection of Water Transportation Engineering-JTS 239-2015

"Technical Regulations for Strength Testing of High Strength Concrete"-JGJ/T294-2013

Technical Specification for Rebound Method and Ultrasonic Rebound Comprehensive Method for Testing Pumped Concrete Strength-DBJ/T01-78-2003

Technical Regulations for Testing Concrete Compressive Strength-DG/TJ08-2020-2007

Technical Specification for Ultrasonic Rebound Comprehensive Method for Testing Concrete Strength-DB37/T 2361-2013

Technical Specification for Ultrasonic Rebound Comprehensive Method for Testing Concrete Strength-DBJ53/T-53-2013

Technical Specification for Ultrasonic Rebound Comprehensive Method for Testing Concrete Strength of Highway Engineering-DB51/T1996-2015

"Technical Specifications for Building Pile Testing"-JGJ 106-2014

"Technical Regulations for Dynamic Testing of Piles in Highway Engineering"-JTG/T F81-01-2004

Technical Regulations for Testing Pile Foundations in Railway Engineering-TB 10218-2008

Code for Building Foundation Testing - DBJ 15-60-2008

"Shenzhen Building Foundation Pile Inspection Procedures"-SJG09-2015

"Technical Specifications for Building Pile Testing"-DGJ08-218-2003

Technical Parameters:

Model | GTJ-U910 Non-Metal Ultrasonic Detector |

Main control unit | Built-in A8 industrial control board |

Display | 10.1 inch, high brightness, TFT color LCD capacitive screen |

Mode of operation | Touch screen |

Storage method | Built-in electronic hard disk (≥48B) + large capacity U disk |

Acquisition mode | Single channel manual point by point acquisition |

Number of channels | 1 transmit +1 receive |

Trigger mode | signal trigger |

Sampling period (μs) | 0.05~409.6 multiple options |

Sound time accuracy (μs) | 0.05 |

Sound time range (μs) | ±1677700 |

Seam width function | Measuring range: 0~10mm; measuring accuracy: 0.01mm; |

Dynamic range (dB) | 146 |

Bandwidth (kHz) | 1~500 |

Receive sensitivity (μV) | ≤10 |

Gain accuracy (dB) | 0.5 |

Transmitting voltage (V) | 65, 250, 500, 1000 four adjustable |

Communication interface | USB, Bluetooth, wifi |

Working time (h) | ≥8 |

Power supply mode | Built-in lithium battery External 220V ~ 16V AC / DC |

Working environment | Temperature (°C)-10°C~+40°C |

Host size (mm) | 300 × 200 × 55 |

Model | GTJ-U920 Non-Metal Ultrasonic Detector |

Main control unit | Built-in A8 industrial control board |

Display | 10.1 inch, high brightness, TFT color LCD capacitive screen |

Mode of operation | Touch screen |

Storage method | Built-in electronic hard disk (≥8GB) + large capacity U disk |

Acquisition mode | Single and dual channel manual point-by-point acquisition |

Number of channels | 1 transmit + 2 receive |

Trigger mode | signal trigger |

Sampling period (μs) | 0.05~409.6 multiple options |

Sound time accuracy (μs) | 0.05 |

Sound time range (μs) | ±1677700 |

Seam width function | Measuring range: 0~10mm; measuring accuracy: 0.01mm Connection method: wifi |

Dynamic range (dB) | 146 |

Bandwidth (kHz) | 1~500 |

Receive sensitivity (μV) | ≤10 |

Gain accuracy (dB) | 0.5 |

Transmitting voltage (V) | 65, 250, 500, 1000 four adjustable |

Communication interface | USB, Bluetooth, wifi |

Working time (h) | ≥8 |

Power supply mode | Built-in lithium battery External 220V ~ 16V AC / DC |

Working environment | Temperature (°C)-10°C~+40°C |

Host size (mm) | 300 × 200 × 55 |

Model | GTJ-U930 Non-Metal Ultrasonic Detector |

Main control unit | Built-in A8 industrial control board |

Display | 10.1 inch, high brightness, TFT color LCD capacitive screen |

Mode of operation | Touch screen |

Storage method | Built-in electronic hard disk (≥8GB) + large capacity U disk |

Acquisition mode | Single and dual channel automatic continuous fast acquisition |

Number of channels | 1 transmit + 2 receive |

Trigger mode | signal trigger |

Sampling period (μs) | 0.05~409.6 multiple options |

Sound time accuracy (μs) | 0.05 |

Sound time range (μs) | ±1677700 |

Seam width function | Measuring range: 0~10mm; measuring accuracy: 0.01mm; |

Dynamic range (dB) | 146 |

Bandwidth (kHz) | 1~500 |

Receive sensitivity (μV) | ≤10 |

Gain accuracy (dB) | 0.5 |

Transmitting voltage (V) | 65, 250, 500, 1000 four adjustable |

Communication interface | USB, Bluetooth, wifi |

Working time (h) | ≥8 |

Power supply mode | Built-in lithium battery External 220V ~ 16V AC / DC |

Working environment | Temperature (°C)-10°C~+40°C |

Host size (mm) | 300 × 200 × 55 |

Model | GTJ-U950 non-metal ultrasonic detector |

Main control unit | Built-in A8 industrial control board |

Display | 10.1 inch, high brightness, TFT color LCD capacitive screen |

Mode of operation | Touch screen |

Storage method | Built-in electronic hard disk (≥8GB) + large capacity U disk |

Number of channels | 3 channels spontaneously received |

Number of disposable sections | 3 |

Trigger mode | signal trigger |

Sampling period (μs) | 0.05~409.6 multiple options |

Sound time accuracy (μs) | 0.05 |

Sound time range (μs) | ±1677700 |

Seam width function | Measuring range: 0~10mm; measuring accuracy: 0.01mm; |

Dynamic range (dB) | 146 |

Bandwidth (kHz) | 1~500 |

Receive sensitivity (μV) | ≤10 |

Gain accuracy (dB) | 0.5 |

Transmitting voltage (V) | 65, 250, 500, 1000 four adjustable |

Communication interface | USB, Bluetooth, wifi |

Working time (h) | ≥8 |

Power supply mode | Built-in lithium battery |

Working environment | Temperature (°C)-10°C~+40°C |

Host size (mm) | 300 × 200 × 55 |

Model | GTJ-U960 Non-Metal Ultrasonic Detector |

Main control unit | Built-in A8 industrial control board |

Display | 10.1 inch, high brightness, TFT color LCD capacitive screen |

Mode of operation | Touch screen |

Storage method | Built-in electronic hard disk (≥8GB) + large capacity U disk |

Number of channels | 4 channels spontaneously received |

Number of disposable sections | 6 |

Trigger mode | signal trigger |

Sampling period (μs) | 0.05~409.6 multiple options |

Sound time accuracy (μs) | 0.05 |

Sound time range (μs) | ±1677700 |

Seam width function | Measuring range: 0~10mm; measuring accuracy: 0.01mm; |

Dynamic range (dB) | 146 |

Bandwidth (kHz) | 1~500 |

Receive sensitivity (μV) | ≤10 |

Gain accuracy (dB) | 0.5 |

Transmitting voltage (V) | 65, 250, 500, 1000 four adjustable |

Communication interface | USB, Bluetooth, wifi |

Working time (h) | ≥8 |

Power supply mode | Built-in lithium battery |

Working environment | Temperature (°C)-10°C~+40°C |

Host size (mm) | 300 × 200 × 55 |

Company Profile

Jinan Wangtebei Instrument and Equipment Co.,ltd, located in the beautiful spring city, specialized in the design, manufacture and selling of material testing machines for metal and nonmetal materials.?Our company has always been adhering to the innovative and ?sustainable development as the service concept, with customer satisfaction as the standard, to provide users with a complete set of material testing solutions. Our company has a professional and experienced mechanical, electrical, electronic, and software R&D and design personnel. It is extremely professional in its industry standards/requirements and keeps up to date with the development trend of the testing machine industry, thus ensuring the company's continuous improvement in new technology research and development; advanced Machining equipment, professional machining equipment operators and standardized quality management processes ensure that the company's product quality is controllable and reliable, making the production products more stable and fine. The sales/after-sales service team is professional, energetic, detailed in division of labor, and considerate in service.?At present, our company mainly produces including: tensile strength tester, hydraulic universal testing machine series, electronic universal testing machine series, manhole cover testing machine, impact testing machine series (including notched broach, cryogenic bath, projector supporting impact testing), cup protrusion testing machine, manhole cover testing machine, horizontal tensile testing machine, bending testing machine , Torsion testing machine, anchor testing machine, relaxation testing machine, hardness tester, metallographic sample preparation instruments and other products, which are widely used in iron and steel metallurgy, machinery manufacturing, shipbuilding, aerospace, ordnance, automotive, railway, pressure vessel, Steel pipes, rubber, plastics, colleges, scientific research units and quality inspection institutions and other industries.?

Contact Us

- jinan wangtebei instrument and equipment co.,ltd

- Contact namesophie Chat Now

- Addressshizhong district, Ji'nan, Shandong

Product Categories

New Products

-

ISO 13426 geocells tensile strength breaking force testing machine

-

wood panel bending modulus testing machine 100kn 10 ton capacity computerized

-

ISO 13426 geocells tensile strength breaking force tester

-

Geocell Material Testing Machine Geocell Joint Strength Test Machine ISO 13426 geocell strip tensile strength tester

-

Geocell welding joint strength testing machine HDPE geocell mechanical testing machine Tensile test machine for plastic geocells

-

Servo controlled tensile test machine for geocells

-

Wood board flexural modulus tester Bending strength tester for wood panels Modulus of elasticity tester for wood boards

-

Bending test machine for plywood and MDF Bending modulus testing equipment for engineered wood Flexural strength testing equipment for wood

-

Wood panel mechanical testing machine for elasticity Bending test machine for OSB, MDF, particleboard

-

EN 310 wood panel testing machine ISO standard flexural tester for wood-based panels

-

Bending modulus tester for furniture boards MOE and MOR tester for laminated wood panels

-

Plywood flexural testing machine supplier Wood panel quality control testing machine

-

Testing equipment for modulus of rupture (MOR) in wood Wood panel MOE MOR testing

-

Elastic modulus measurement equipment Flexural test machine for wooden materials

-

Modulus of elasticity and rupture test setup Wood composite mechanical testing system

-

YJZ-1000E Computer Controlled Bolt Torsion Test Machine

-

Fully automatic bolt torsion test equipment Bolt torque and rotation angle tester

-

Computerized torsion testing machine for bolts Bolt torsion test machine with angle and torque display

-

ISO 16047 bolt torsion testing machine Automated torque test machine for bolts and fasteners

-

torsion testing machine for automotive bolts High-precision bolt torque tester

-

Torsion testing machine for automotive bolts High-precision bolt torque tester Bolt performance test machine for factories

-

Fastener torsional failure testing equipment Laboratory bolt torsion test system

-

Torque vs angle bolt test machine Bolt torsion test system with data acquisition

-

Digital torque and angle measurement equipment ASTM F606 torsion testing machine EN ISO 16047 bolt torque test standard

Popular Searches

Find Similar Products By Category

- Instruments & Meters > Test Instrument > Test Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sophie

Hi there! Welcome to my shop. Let me know if you have any questions.

sophie

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile