Product Description

I. Overview

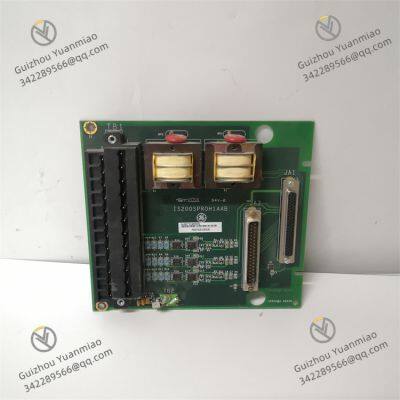

GE IS200SPROH1AAB is a key module that plays a pivotal role in its Mark VI series control systems. As a high-end PLC control module, it integrates General Electric's advanced technical concepts. With excellent functions, reliable performance and outstanding environmental adaptability, it has become a powerful assistant in many complex projects in the fields of industrial automation and energy management, providing solid control and monitoring guarantees for various industrial applications.

II. Technical Parameters

Power parameters: The input voltage is 24V DC, providing reliable power support for the stable operation of the module. At the same time, it has good power adaptability and can work normally in a certain range of voltage fluctuations, reducing the impact of unstable power supply on the module's performance. Some models are also equipped with a dual redundant power supply design, which further improves the power supply reliability in critical mission scenarios, ensuring that even if one power supply fails, the module can still operate continuously and stably, avoiding equipment downtime caused by power supply problems.

Communication interface: It supports RS-232 interface, which can be used for communication connection with some traditional industrial equipment to achieve compatibility with early industrial control systems. At the same time, relying on the support of multiple mainstream communication protocols, through different communication interfaces, such as Ethernet interfaces, it can be easily connected to the industrial automation network, and perform high-speed and stable data interaction with other intelligent equipment and control systems, meeting the diverse needs for equipment communication in modern industrial production.

Temperature range: The working temperature range is between -40°C and 70°C, showing strong environmental adaptability. It can operate stably both in cold northern winter outdoor industrial facilities, such as outdoor control cabinets of wind power plants, and in high-temperature industrial production workshops, such as steel smelters and glass factories, ensuring that the normal operation of the equipment is not affected by extreme temperature environments.

Number of channels: As mentioned earlier, it has eight analog voltage input channels for accurately collecting various analog signals. In terms of digital signal processing, it also has multiple digital input/output channels, which can flexibly connect various digital sensors and actuators according to actual application needs, realizing comprehensive control and monitoring of industrial equipment.

Resolution and accuracy: The analog voltage input channel has high resolution, reaching 0.2 mV (for -5 to +5 VDC) and 0.4 mV (for -10 to +10 VDC) under different configurations, and the cross-range accuracy is maintained at 0.05%, ensuring that the collected analog signal data is accurate and reliable. In terms of digital signal processing, it also has high-precision computing and processing capabilities, which can accurately analyze and convert various digital signals, providing strong support for precise control in industrial production.

Protection level: The protection level reaches IP20, which can effectively prevent solid foreign objects with a diameter larger than 12.5mm from entering the module, providing a certain degree of protection for internal precision circuits. Although this protection level is suitable for general industrial environments and can work stably in scenarios with less dust and small particle impurities, for some industrial places with more dust and harsh environments, additional protective measures, such as installation in a control cabinet with a higher protection level, can be taken to further ensure the normal operation of the module.

Size and weight: It adopts a standard industrial module size design, with specific dimensions of 178 mm (height) × 102 mm (width) × 254 mm (depth) and a weight of approximately 2.3 kg. This size design is convenient for installation together with other standard-compliant industrial modules in industrial control cabinets, equipment racks and other spaces, facilitating the construction of compact and efficient industrial control systems. At the same time, the reasonable weight also facilitates handling and operation during equipment installation and maintenance.

Installation method: It supports two common industrial installation methods: DIN rail installation and panel installation. The DIN rail installation method is simple and fast, and the module is stable and reliable after installation, facilitating rapid deployment and later maintenance and replacement in industrial sites; panel installation is suitable for some industrial equipment with special requirements on installation space and appearance, and users can flexibly choose the installation method according to actual needs.

III. Core Functions

Precise processing of multiple types of signals

Analog voltage input: It has eight analog voltage input channels, and each channel has flexible configuration capabilities, which can be conveniently set to the operating range of -5 to +5 VDC or -10 to +10 VDC according to the needs of actual application scenarios. When working in the -5 to +5 VDC range, the resolution can reach 0.2 mV; when switched to the -10 to +10 VDC range, the resolution can also be maintained at 0.4 mV. Such high-resolution analog voltage input capability enables the module to accurately capture signal changes when faced with analog signal acquisition tasks such as temperature, pressure, and flow, providing a high-precision data foundation for subsequent data analysis and processing, and meeting the strict requirements for monitoring various analog quantities in the industrial production process.

Digital signal processing: Equipped with a powerful digital signal processor with a stable operating frequency of 60 MHz. It can efficiently and quickly process digital signals from various sensors, such as key data like turbine speed and equipment vibration frequency. Through precise digital signal processing algorithms, these data are analyzed and calculated, and then accurate control commands are provided for the control system to ensure that industrial equipment operates stably according to preset parameters, effectively avoiding equipment failures and production accidents caused by untimely or inaccurate signal processing.

High-precision measurement ensures stable operation: In terms of measurement accuracy, GE IS200SPROH1AAB performs excellently, with a cross-range accuracy of up to 0.05%. Taking the common 10 VDC measurement scenario as an example, the accuracy can reach 5 mV; at 5 VDC, the accuracy can also be maintained at 2.5 mV. Such high accuracy indicators are of crucial significance in the industrial production process, whether for monitoring equipment operating parameters or for precise control of production processes. It can ensure that equipment always operates in the best condition, improve the stability of product quality, and reduce the defect rate and low production efficiency caused by measurement errors.

Convenient communication realizes system interconnection

Multi-protocol support: The communication function is very powerful, supporting multiple mainstream communication protocols such as Modbus, TCP/IP, ControlNet, and EtherNet/IP. As a widely used standard protocol in the field of industrial communication, the Modbus protocol ensures seamless data interaction between it and many industrial equipment and control systems that follow this protocol, facilitating the construction of distributed industrial control systems. The TCP/IP protocol provides a basis for the module to access the enterprise network, realize remote monitoring and data transmission, and meets the needs of equipment interconnection and centralized management and control in the Industry 4.0 era. ControlNet and EtherNet/IP protocols further expand the application range of the module in industrial automation networks, enabling efficient communication with different types of automation equipment and realizing automated collaborative control of the entire production process.

Diverse communication interfaces: It supports the selection of various RocketPort INFINITY cards, covering different types of cards with 4, 8, 16, or 32 ports, and users can flexibly configure according to actual communication needs. At the same time, both the cable connection method and the interface form of PCI or PCI-X expansion slots provide a variety of options for the module to establish communication links with other equipment, greatly improving its communication adaptability and expandability in different industrial environments.

Reliable protection and diagnostic functions

Fault monitoring and alarm: Built-in precision fault monitoring mechanism, which can real-time monitor its own working status and the operation of connected equipment. Once an abnormal situation is detected, such as signal loss, voltage abnormality, equipment failure, etc., it will immediately remotely transmit messages such as concentration alarm levels, required maintenance, ongoing services, and instrument faults through the relay function that conforms to the NAMUR standard. Operators can timely grasp the key operating status information of the equipment without being present at the equipment site, quickly respond to equipment failures, arrange maintenance work, effectively reduce the risk of equipment downtime, and ensure the continuity of industrial production.

Self-diagnosis and repair: It has a powerful self-diagnosis function, which can perform regular or real-time self-inspection on its own hardware, software, and internal circuits. Through the analysis of the detection data, potential fault hidden dangers are found in time, and attempts are made to perform self-repair. For example, when a short-term abnormality is detected in a communication interface, the module can automatically restart the interface to try to restore normal communication. For faults that cannot be repaired by itself, detailed fault information will be recorded, providing an accurate reference for subsequent maintenance work, greatly shortening the time for equipment fault detection and repair, and improving the operation and management efficiency of the equipment.

GE IC698PSD300C Power Module

GE IC698PSA350E Power Module

HONEYWELL FC-USI-0001 Universal Security Interface Module

GE IC695CPE310-ABAB Analog I/O Module

GE IC695CPU320-CF Power Module

HONEYWELL FE-USI-0002 Universal Security Interface Module

GE 531X306LCCBAG3 Ethernet port Module

GE 531X301DCCAFG2 Drive Control Card

HONEYWELL TC-OAV081 Analog Output Module

GE IS220PSCAH1A 336A4940CSP9 Serial Modbus Communication

GE IS220PDIAH1BE 336A5026ADP4 Discrete I/O Package

GE IS220PDOAH1A 336A4940CSP2 Discrete Output Pack

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.