Product Description

I. Product Overview

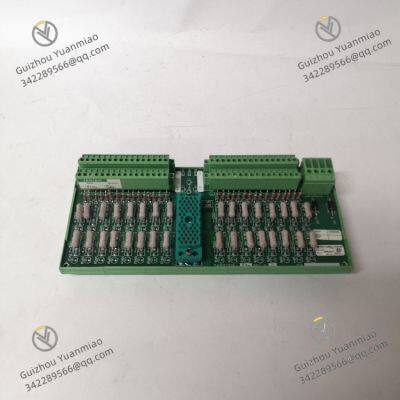

TRICONEX 9566-8XX is one of the core components of the Triconex series products under Honeywell, and it is a key module of the Safety Instrumented System (SIS). This series of products is renowned for its high reliability and safety, specially designed for industrial process safety applications, providing a high level of fault detection and fault tolerance functions.

The 9566-8XX module adopts a Triple Modular Redundant (TMR) structure, consisting of three identical system branches. This unique design ensures that the system can still operate normally in the case of a single point of failure, thereby providing excellent reliability and fault tolerance, and effectively ensuring the continuity of industrial processes. The module is mainly used to perform safety logic control and monitoring functions, supporting digital input/output, analog signal processing, and safety logic operations. It is suitable for various industrial environments and plays an important role in critical fields such as petrochemical, electric power, pharmaceutical, and water treatment, where high requirements for safety and stability are demanded.

II. Technical Parameters

(1) Electrical Parameters

Power Supply Voltage: Usually 24V DC. The stable DC voltage input provides a basic guarantee for the reliable operation of the module and meets the general requirements for power supply of most industrial automation equipment.

Input Current: 5A. The reasonable input current design ensures that the module can stably obtain the required energy when connected to various signal sources, guaranteeing the normal execution of signal processing and control functions.

Output Current: 2A. This output current can meet the needs of driving various industrial actuators and equipment, and can effectively control the operation of devices such as valves and motors.

(2) Physical Parameters

Dimensions: Common specifications include 120mm x 80mm x 30mm or 100mm x 50mm x 25mm, etc. The compact design allows it to be easily installed in industrial control cabinets with limited space without occupying too much valuable space, facilitating integration into various industrial control systems.

Weight: Approximately 200 grams. The lightweight design not only facilitates installation and transportation but also can well meet the needs in some special application scenarios with strict requirements on equipment weight.

Operating Temperature Range: -40℃ to 70℃ or -40℃ to 85℃ (depending on different models). Such a wide operating temperature range enables the module to work stably in various harsh industrial environments, whether in high-temperature smelting workshops, low-temperature cold storage environments, or even outdoor places with drastic temperature changes, without affecting its performance.

(3) Performance Parameters

Communication Interfaces: Supports multiple communication interfaces such as Ethernet and RS485, enabling efficient data interaction with industrial equipment and control systems of different brands and types, realizing the interconnection and collaborative work of the system. Through the Ethernet interface, it can quickly communicate with the factory's central control system, upload equipment operation data, and receive production task instructions; the RS485 interface is suitable for application scenarios that require a certain transmission distance and stable data transmission in complex electromagnetic environments.

Number of I/O Channels: Supports multiple configurations. According to actual industrial application needs, different combinations of digital input/output and analog input/output channels can be flexibly selected to meet diverse control requirements. For example, in automated production lines that require a large number of digital controls, more digital input/output channels can be configured to monitor equipment status and control equipment actions; in chemical production processes that require precise control of analog parameters such as temperature, pressure, and flow, the configuration of analog input/output channels can be increased.

Communication Protocols: Supports multiple communication protocols such as Modbus, OPC, and DNP3, facilitating integration and data exchange with other control systems and equipment. The Modbus protocol, due to its openness and wide application, allows the 9566-8XX module to easily communicate with a large number of industrial equipment that supports this protocol; the OPC protocol provides a unified standard interface for data interaction between automation equipment and software from different manufacturers, ensuring the accuracy and stability of data transmission; the DNP3 protocol is often used in fields such as power systems that have high requirements for real-time performance and reliability, and the support of the 9566-8XX module for this protocol enables it to play an important role in power-related industrial scenarios.

III. Functional Characteristics

(1) High Reliability

Adopting a triple redundant design, the three system branches operate simultaneously and perform mutual comparison and verification. When one of the branches fails, the other two normal branches can continue to maintain the normal operation of the system, ensuring the stability and safety of the system in critical operating environments. This redundant design greatly reduces the risk of system shutdown due to a single point of failure, and is a key factor in ensuring production continuity and safety for industries such as petrochemical and electric power that require continuous production and high system reliability. For example, in the petrochemical production process, if the control system fails, it may cause serious safety accidents and huge economic losses, but the high reliability design of TRICONEX 9566-8XX can effectively avoid such situations.

(2) Fault Tolerance

It can continue to operate in the case of a single point of failure and has a strong fault diagnosis and handling mechanism. When a fault in a certain branch is detected, the system will automatically isolate the faulty branch and maintain the system operation through other normal branches. At the same time, the module will record fault information in real-time for maintenance personnel to troubleshoot and repair later. This fault tolerance ensures production safety and can ensure the continuous and stable operation of the system even in complex and changing industrial environments. For example, in power systems, factors such as grid fluctuations and electromagnetic interference may cause temporary faults in the control module. With its excellent fault tolerance, 9566-8XX can quickly handle the fault without affecting power supply, ensuring the stable operation of the power system.

(3) High Performance

It supports real-time digital input and output applications and has powerful logic control and fault diagnosis functions. The dedicated safety processor it adopts can quickly and accurately process complex control logic and algorithms, realizing high-precision control of industrial equipment and production processes. In industrial scenarios that require precise control of parameters such as flow, temperature, and pressure, it can complete tasks excellently, ensuring the stability of the production process and the consistency of product quality. For example, in the pharmaceutical industry, the production process of drugs has extremely high requirements for the control accuracy of parameters such as temperature and pressure. The 9566-8XX module can adjust the control strategy in real-time according to preset process requirements to ensure that drug quality meets strict standards. At the same time, its powerful fault diagnosis function can timely detect potential fault hazards in the system, take preventive measures in advance, reduce equipment failure rates, and improve production efficiency.

(4) Modular Design

It is convenient for installation, maintenance, and expansion. Each functional part of the module adopts a modular structure, and modules with different functions can be flexibly combined and configured according to actual needs. During installation, the corresponding module can be installed by simply inserting it into a suitable slot, and the operation is simple and convenient. In terms of maintenance, when a module fails, maintenance personnel can quickly locate and replace the faulty module without large-scale disassembly and debugging of the entire system, greatly reducing equipment downtime. Moreover, with the expansion of enterprise production scale or the improvement of processes, the system can be expanded and upgraded by adding or replacing modules to meet the ever-changing industrial control needs. For example, in the automated production line of an automobile manufacturing enterprise, with the update of vehicle models and the optimization of production processes, it may be necessary to add some new control functions. At this time, the expansion and upgrading of the system can be easily realized by adding corresponding modules.

(5) Flexibility

It supports multiple communication protocols and I/O types, adapting to the needs of different industrial scenarios. Whether it is a simple single-machine control system or a complex multi-machine linkage automated production line, seamless integration with other equipment and systems can be achieved by selecting appropriate communication protocols and I/O configurations. In the construction of smart factories, the 9566-8XX module can perform high-speed and stable data transmission with the factory's central control system, on-site sensors, actuators, and other control systems through different communication protocols, realizing the interconnection and intelligent management of the entire factory production system. For example, in an industrial automation workshop containing equipment of multiple brands, the 9566-8XX module can communicate with some equipment through the Modbus protocol and with another part of the equipment through the OPC protocol, thereby realizing unified control and management of the entire workshop equipment.

(6) Safety

It meets the requirements of SIL 3 safety level and complies with the IEC 61508 functional safety standard. This means that the module follows strict safety specifications and standards in the design, development, testing, and maintenance processes, and can effectively prevent and control safety risks in the industrial production process. For industrial fields involving personal safety, environmental protection, and major economic losses, such as the chemical and energy industries, its high safety ensures the safe and reliable operation of the production process. For example, in chemical production, flammable and explosive hazardous chemicals may be involved, and the high safety level of the 9566-8XX module can ensure the safe monitoring and control of the production process under various complex working conditions, preventing accidents.

IV. Application Scenarios

(1) Petrochemical Industry

In the petrochemical production process, there are many dangerous process links involving high temperature, high pressure, flammability, and explosiveness, which have extremely high requirements for the safety and reliability of control systems. The TRICONEX 9566-8XX module can be used to monitor key parameters such as pressure, temperature, and liquid level of reactors. Once the parameters exceed the safe range, it will quickly execute safety logic control, such as closing valves and starting emergency cooling systems, to ensure the safety of the production process. At the same time, in all links of oil and gas extraction, transportation, and processing, this module can also be used to monitor and control various equipment in real-time to ensure the stable operation of the entire petrochemical production process. For example, in an oil refinery, the 9566-8XX module is used to precisely control equipment such as distillation towers and cracking furnaces, optimize the production process, and improve product quality and production efficiency.

(2) Electric Power Industry

In power systems such as power plants and substations, the TRICONEX 9566-8XX module plays an important role. It can be used for protection, control, and monitoring of power systems, such as real-time monitoring and adjustment of parameters such as the speed, voltage, and current of generators to ensure the stable operation of generators. In substations, it can realize remote control and status monitoring of equipment such as circuit breakers and disconnectors, improving the automation level and reliability of power systems. In addition, when a fault occurs in the power system, the 9566-8XX module can quickly detect the fault and execute corresponding protection actions, such as cutting off the faulty line to prevent the fault from expanding, ensuring the safe and stable operation of the power system. For example, in the construction of smart grids, this module can work together with other smart devices to realize real-time monitoring and optimal control of the power grid, improving the power supply quality and reliability of the power grid.

(3) Pharmaceutical Industry

The pharmaceutical production process has extremely strict requirements on the control accuracy of environmental conditions and process parameters, which is directly related to the quality and safety of drugs. The TRICONEX 9566-8XX module can be used in the environmental control system of pharmaceutical workshops to precisely control parameters such as temperature, humidity, and cleanliness, providing stable environmental conditions for drug production. In terms of controlling pharmaceutical production equipment, such as reactors, filling machines, and packaging machines, precise control and monitoring of equipment operating parameters are realized through this module to ensure that the pharmaceutical production process meets strict GMP (Good Manufacturing Practice) standards. For example, in the vaccine production process, small deviations in parameters such as temperature and pressure may affect the quality and effectiveness of the vaccine. The 9566-8XX module can ensure the stability and consistency of the vaccine production process with its high-precision control capability.

(4) Water Treatment Industry

In water treatment facilities such as waterworks and sewage treatment plants, the TRICONEX 9566-8XX module can be used for the automatic control of the water treatment process. Through real-time monitoring of water quality parameters (such as pH, turbidity, residual chlorine, etc.) and precise control of water pumps, valves, dosing equipment, etc., the optimized operation of the water treatment process is realized. For example, in the water purification process of a waterworks, according to changes in raw water quality, the 9566-8XX module automatically adjusts the dosage and operating parameters of filtration equipment to ensure that the quality of the effluent water meets national standards. In sewage treatment plants, the operation of sewage treatment equipment can be controlled in real-time according to the flow and quality of sewage, improving sewage treatment efficiency and reducing energy consumption.

(5) Rail Transit Industry

In the field of rail transit, the TRICONEX 9566-8XX module can be used in signal control systems to precisely control equipment such as signal lights and turnouts, ensuring the safe and smooth operation of trains. Through communication and collaborative work with other train control systems, automatic operation, scheduling, and monitoring of trains are realized. For example, in the urban subway system, the 9566-8XX module can control the display of signal lights in real-time according to information such as the position and running speed of the train to ensure that a safe distance is maintained between trains. At the same time, the precise control of turnouts enables safe switching of trains between different tracks, improving the efficiency and reliability of subway operations.

IS420UCSCH2A GE Dual core controller module

IS215VCMIH2CB GE VME bus main controller board

GE V7668A-1310B0 350-9310007668-131020 D Single-Board Computer

IS420UCSBH3A GE UCSB controller

IS420UCSCH1B GE Four core controller module

GE V7668A-131000 350-9310007668-131000 B Single-Board Computer

IC697CPX935-CD GE Central Processing Unit (CPU) module

GE VMIVME-7750-744001 350-027750-744001 F Single-Board Computer

IS400JPDHG1ABB GE High density distribution board

IS200WROBH1AAA GE Power detection board

GE VET2-A21010 350-9300007672-12F010 A1 Single-Board Computer

GE IS215UCVHM06A Controller

GE IS215UCVHM06A Control Board Brand

GE IS215UCVHM06A Functional safety controller

IS220PPDAH1A Feedback board for power distribution system

IS200TREGH2B Gas turbine emergency trip terminal board

DS200PCCAG9ACB power supply and control card

VMIVME-2540-300 Intelligent Counter/Controller for VME Bus Architecture

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.