Product Description

I. Product Overview

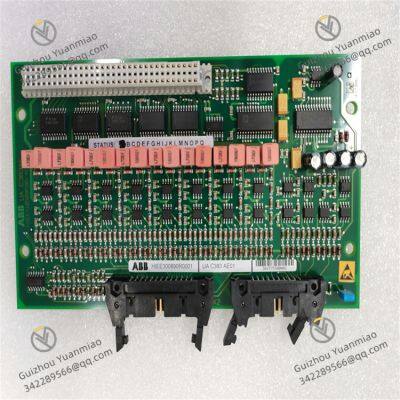

As a key member of the ABB Ability? System 800xA series, ABB HIEE300890R0001 plays an indispensable role in various industrial scenarios with its excellent performance and design. Essentially, it is a redundant binary input module, tasked with accurately converting complex binary signals from on-site equipment into electrical signals that are easy for controllers to process, serving as an important link connecting the field layer and the control layer.

In petrochemical production facilities, the opening/closing status of numerous valves and the start/stop signals of pumps need to be fed back to the control system in real-time and accurately. HIEE300890R0001, with its powerful signal acquisition and conversion capabilities, quickly and error-free transmits these binary signals to the controller, assisting the control system in finely controlling the entire production process. In automated production lines of smart factories, binary signals such as material positions and equipment operating status fed back by sensors are also efficiently transmitted by HIEE300890R0001, providing a solid guarantee for the orderly operation of production systems. It is widely used in multiple industrial fields such as power, oil and gas, chemicals, water treatment, metal processing, food and beverage, textiles, and automotive manufacturing, promoting industrial automation to a higher level with its stable and reliable performance.

II. Technical Parameters

(I) Parameters Related to Input Signals

Input Type and Number of Points: Adopts binary input type, precisely adapting to common switching signals in industrial sites. It has 8 independent input channels, each capable of independently collecting one binary signal, and can connect 8 different on-site equipment signal sources simultaneously. Whether it is multiple limit switches, proximity switches, or other sensors with binary output, parallel acquisition can be achieved, greatly improving signal acquisition efficiency and meeting the demand for multi-signal source monitoring in medium-scale automated control systems.

Input Voltage Range and Current: The input voltage range is designed as 24V DC, which is highly compatible with DC power supply systems widely used in industrial sites, ensuring stable operation in common power supply environments. Each input channel has a current of 2A, which, while ensuring stable signal transmission, has a certain load-driving capability, allowing direct connection to some on-site equipment that requires a larger driving current, reducing intermediate conversion links and improving system reliability.

(II) Electrical Performance Parameters

Working Power Supply and Power Consumption: The working power supply is 24V DC, consistent with the input signal voltage, facilitating unified power supply design of the system and reducing the complexity of power management. The overall power consumption of the module is low, less than 5W, which does not generate excessive heat during long-term operation, effectively reducing the system's heat dissipation burden, and is also conducive to energy conservation, conforming to the trend of modern industrial energy conservation.

Isolation and Surge Protection Parameters: In industrial sites, electrical interference and voltage abnormalities are common problems. HIEE300890R0001 adopts advanced isolation technology with an isolation voltage of up to 2500V, which can effectively isolate input channels from other parts of the system, preventing signal interference between channels and the impact of external high voltage on the system. At the same time, it has excellent surge voltage protection capability, capable of withstanding a surge voltage of 2500V, which can protect the module and the backend control system even in extreme cases such as power fluctuations and lightning strikes, ensuring stable operation of the system.

(III) Physical and Installation Parameters

Dimensions and Weight: The module adopts a compact design concept, with external dimensions of 50mm × 50mm × 10mm. Its small size allows easy installation in environments with limited space such as control cabinets, saving valuable installation space. It weighs approximately 0.32kg, and the lightweight design facilitates operation by on-site installation and maintenance personnel, reducing physical exertion during installation.

Installation Methods and Environmental Adaptability: Supports multiple installation methods, which can be flexibly selected according to actual application scenarios. The operating temperature range is -20°C to +60°C (some models can reach -40°C to +85°C), enabling normal operation in both cold warehouse environments and high-temperature smelting workshops. The relative humidity adaptation range is 5% - 95% (no condensation), and it can maintain stable performance in humid food processing workshops, water treatment plants near water sources, and other environments. The protection level can reach IP20 or IP67 depending on the model. The IP20 protection level can effectively prevent dust from entering and protect internal circuits; the IP67 protection level has stronger waterproof and dustproof capabilities, and can operate reliably in harsh outdoor environments or environments with liquid splashing.

(IV) Signal Response Parameters

The signal response time is less than 10ms, and this fast response characteristic is particularly crucial in the status monitoring of high-speed operating automated equipment. In automated production lines, equipment runs at high speed, material transmission and equipment action switching are frequent. HIEE300890R0001 can capture changes in on-site equipment status in a very short time and transmit the signal to the controller, ensuring that the control system makes correct responses in a timely manner and avoiding production accidents or efficiency reduction caused by signal delay.

III. Functional Characteristics

(I) High-Reliability Redundant Design

Input Channel Redundancy: The 8 input channels of HIEE300890R0001 adopt a redundant design, that is, each channel has a backup channel. When the main channel fails, such as line short circuit, open circuit, or internal circuit damage of the channel, the backup channel will immediately switch seamlessly, continue to collect and transmit signals, ensuring that the status information of on-site equipment is continuously transmitted to the controller, and maintaining the stable operation of the production system. In a continuously operating chemical production line, if the main channel of a valve status monitoring channel fails suddenly, the redundant channel can take over immediately, ensuring that the valve status can be fed back in real-time and avoiding confusion in the production process caused by signal loss.

Control Circuit and Power Supply Redundancy: In addition to input channel redundancy, the control circuit and power supply part of the module also adopt redundant design. The redundant control circuit ensures that when the main control circuit is abnormal, the backup circuit can start quickly, ensuring the normal processing and transmission logic of the module for input signals. The redundant power supply supplies power to the module in a timely manner when the main power supply fails, such as voltage fluctuation, power failure, etc., maintaining the continuous operation of the module, effectively reducing the risk of system shutdown caused by power supply problems, and greatly improving the reliability of the entire system.

(II) High-Precision Signal Processing

Accurate Signal Recognition: Equipped with advanced signal recognition algorithms and filter circuits, it can accurately distinguish effective binary signals from interference signals. In the complex electromagnetic environment of industrial sites, motors, frequency converters, and other equipment will generate a large amount of electromagnetic interference. HIEE300890R0001 can filter out these interference signals through internal filter circuits, and only transmit effective signals that truly reflect the equipment status to the controller, ensuring that the signals received by the controller are accurate and error-free, providing a reliable basis for the logical judgment and control decision of the system. In the steel smelting workshop, in a strong electromagnetic interference environment, the module can accurately identify the signal of the crane limit switch, avoiding misjudgment caused by interference and ensuring the safe operation of the crane.

Stable Signal Transmission: In the process of signal transmission, through optimized circuit design and signal amplification technology, it ensures that the signal is not distorted or attenuated during long-distance transmission or in complex electromagnetic environments. Even if the connecting cable between the on-site equipment and the module is tens of meters long, or there are strong electromagnetic interference sources around, HIEE300890R0001 can stably transmit the collected signals to the controller, ensuring the system's accurate perception and real-time control of the on-site equipment status.

(III) Convenient Installation and Maintenance Design

Clear Wiring and Indication: The front panel of the module is equipped with clear terminal blocks, each with a clear mark corresponding to the corresponding input channel, facilitating on-site installers to quickly and accurately connect the cables of on-site equipment and reducing wiring errors. At the same time, each channel is equipped with an LED indicator light. When the channel collects an effective signal, the indicator light is on. Maintenance personnel can intuitively judge the working status of the channel through the indicator light, quickly locate the faulty channel, and improve maintenance efficiency. During equipment inspection, maintenance personnel can directly understand the signal collection status of each channel through the indicator light status without the need for additional detection equipment.

Diagnosis and Remote Maintenance Support: HIEE300890R0001 supports diagnostic communication with the upper computer system, and can feed back its own working status, such as power status, channel fault information, communication status, etc., to the upper computer in real-time. When the module fails, the upper computer system can send alarm information in a timely manner and provide a detailed fault diagnosis report, so that maintenance personnel can quickly troubleshoot the cause of the fault according to the report. Some models also support remote maintenance function. When the equipment fails, technicians do not need to be present at the site, and can diagnose and repair the module through remote connection, which greatly shortens the fault handling time, reduces maintenance costs, and improves the availability of the production system.

ABB XVC768101 3BHB007211R101 Printed Circuit Board

ABB XVC768115 3BHB007211R115 Printed Circuit Board

ABB LDMUI-01 I/O Powerhouse Module

ABB LDSTA-01 Automation I/O Module

ABB LDMTR-01 I/O Module

ABB PM866 3BSE050200R1 Processor Unit Kit

ABB PM858 3BSE093350R1 Processor Unit Kit

ABB D1031SH45TS02 Insulated Gate Bipolar Transistor

ABB D1961SH45TS02 Insulated Gate Bipolar Transistor

ABB 3BHL000986P0006 IGBT Module

ABB SYNCHROTACT 5 SYN5202A Control System Module

ABB SYN5201a-Z,V217 Synchronous Device

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.