Home > Products > Nickel Based Alloy > High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy Components

High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy Components

- 0 Piece / Pieces per Month

- Shanghai

- T/T L/C PayPal D/P Western Union Other

- 7 days

You May Like

-

Inconel 600 Forgings - Steam Oxidation Resistance, Heat Exchangers | Industrial Superalloy Parts

-

Gr1 Titanium Bars (Commercial Pure) – High Corrosion Resistance, Annealed/Hot Rolled – Factory Direct Supply

-

Gr2 Pure Titanium Rods – ASTM B348 Certified, Excellent Formability – Custom Cut to Length, Quick Delivery

-

Gr5 Titanium Alloy Bars (Ti-6Al-4V) – Aerospace-Grade Strength, Heat Treated – AMS 4928 Compliant, In-Stock

-

Gr7 Titanium-Palladium Bars (Ti-Pd Alloy) – Superior Corrosion Resistance in Sea Water/Chemicals – Mill Finish or Polished

-

Gr12 Low-Alloy Titanium Bars – High Temperature Stability (≤500°C), Weldable – For Heat Exchangers & Petrochemical Equipment

Product Details

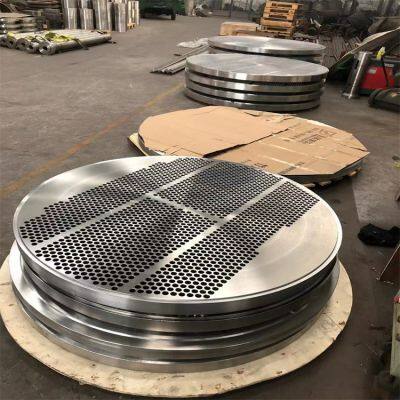

| Type | Nickel based precision alloy | Shape | Other, Customize according to the blueprint | |

| Surface Treatment | Polishing | Transport Package | Wooden crate | |

| Specification | Customize according to the blueprint | Origin | China |

Product Description

Product Details: High-Quality Forgings for Global Industrial Applications

We specialize in manufacturing precision-forged components tailored for extreme industrial environments, covering superalloy forgings, nickel-based alloy forgings, and custom forged parts. Engineered to meet rigorous international standards, our products deliver exceptional performance in high temperatures, corrosive conditions, and heavy-load scenarios—ideal for aerospace, oil & gas, chemical processing, and power generation sectors worldwide.

Core Advantages

? Premium Materials: Crafted from high-purity alloys (Inconel, Hastelloy, Monel, Incoloy, etc.) with strict composition control, ensuring consistent mechanical properties (tensile strength 550–1450 MPa) and resistance to oxidation, corrosion, and creep.

? Extreme Environment Adaptability:

? High-Temp Stability: Withstand continuous service temperatures up to 1200°C (e.g., Inconel 601, Hastelloy X), making them suitable for furnaces, gas turbines, and jet engines.

? Corrosion Resistance: Resist harsh chemicals (sulfuric acid, hydrochloric acid), saltwater, and sulfide environments (e.g., Hastelloy C276, Monel 400), ideal for chemical reactors and marine equipment.

? Mechanical Durability: Excellent creep resistance, thermal fatigue resistance, and high strength-to-weight ratio, ensuring long service life in heavy-load applications (e.g., aerospace turbine disks, oil well downhole tools).

? Precision Forging Technology: Advanced hot/cold forging processes achieve tight tolerances (±0.02mm) and dense microstructures, enhancing structural integrity. Customizable in sizes (thickness 5–1000mm, length up to 12m) to fit unique project requirements.

Key Materials & Applications

Category | Main Alloys | Core Properties | Typical Applications |

Superalloy Forgings | Inconel 718/625/600, Hastelloy X, Haynes 282 | High-temp strength, creep resistance, oxidation proof | Aerospace turbine disks, jet engine blades, gas turbine combustors, industrial furnaces |

Nickel-Based Alloy Forgings | Monel 400/K-500, Incoloy 825/800H, Hastelloy C276 | Corrosion resistance, saltwater proof, acid resistance | Marine valves, chemical tanks, oil well downhole tools, pharmaceutical reactors |

Custom Forged Components | Alloy-specific forgings (per client specs) | Tailored strength, wear resistance, or thermal stability | Power generation equipment, structural aerospace parts, heavy machinery components |

Quality & Certification

? Compliance with Global Standards: Meet ASTM (B564, B637), ASME (SB336, SB564), ISO 9001, and NADCAP requirements, with material certificates (MTR) and third-party testing reports (UT, MT, RT) available.

? Rigorous Quality Control: Each forging undergoes strict inspection—from raw material verification to final dimensional checks—ensuring zero defects and consistent performance.

Customization & Support

? Flexible Specifications: Customizable in size (thickness 5–1000mm, length up to 12m), surface finish (pickled, polished, or coated), and heat treatment (annealing, aging) to match your exact needs.

? Global Service: Offer OEM/ODM solutions, with multilingual technical support, prompt lead times, and flexible logistics (FOB, CIF) to major ports worldwide. Documentation includes commercial invoices, packing lists, and customs declarations for seamless cross-border shipping.

Whether you need high-temp superalloy forgings for aerospace turbines or corrosion-resistant nickel-based forgings for chemical tanks, we deliver reliable, long-lasting solutions. Contact us today for a tailored quote and technical consultation.

Your Trusted Partner for Forgings in Extreme Environments—Globally Delivered.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

| Titanium Alloy | Nickel Based Alloy | Stainless steel pipe |

New Products

-

Titanium Grade 1 Plate - ASTM B265 Certified, Mill Finish, Custom Cut to Size

-

Titanium Grade 2 Plate - Annealed Condition, ISO 9001:2015 Certified, Ready to Ship

-

Titanium Grade 5 Plate (Ti-6Al-4V) - High Strength, Aerospace Grade, CNC Machining Available

-

Titanium Grade 7 Plate (Ti-Pd Alloy) - Corrosion Resistant, Medical-Grade, Polished Surface

-

Titanium Grade 12 Plate (Ti-0.3Mo-0.8Ni) - Excellent Weldability, Industrial Grade, Mill Test Certificates

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar Stock

-

ASME B865 Compliant N05500 Bar Stock | Marine-Grade Corrosion-Resistant Monel K-500 Alloy Bars

-

ASTM B166 Compliant Inconel 600 Bar Stock | High-Temperature & Oxidation-Resistant Nickel-Chromium Bars

-

ASME SB-166 Certified N06600 Round Bar | Heat-Resistant Inconel 600 Alloy Bars for Industrial Use

-

ASTM B446 Compliant Inconel 625 Superalloy Bar | High-Strength Corrosion-Resistant Bar Stock

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy Bars

-

ASTM B637 Compliant Inconel 718 Premium Round Bar | High-Temperature Strength & Fatigue-Resistant Bars

-

ASME SB-637 Certified N07718 Round Bar | Creep-Resistant Machinable Inconel 718 Alloy Bars

-

ASTM A312 TP317L Seamless Stainless Steel Tubes | High Pitting Corrosion Resistance for Chemical Industry

-

ASTM A312 TP310S Seamless Stainless Steel Tubes | 1200℃ High-Temperature Oxidation Resistance for Furnace Applications

-

ASTM A312 TP309S Seamless Stainless Steel Tubes | Carburization-Resistant for High-Temperature Furnace Systems

-

ASTM A312 TP347H Seamless Stainless Steel Tubes | Niobium-Stabilized for High-Temperature Strength in Power Plants

-

ASTM A312 904L Seamless Stainless Steel Tubes | High Molybdenum-Nickel for Severe Corrosion Environments

-

ASTM A312 N08904 Seamless Stainless Steel Tubes | UNS N08904 High-Performance for Harsh Chemical Media

-

Cut to length Alloy 36 steel plate UNS K93603 Invar 36 Corrosion Resisting

-

Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy Components

-

Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy Forgings

-

Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy Parts

Recommended Products

- Inconel 600 Forgings - Steam Oxidation Resistance, Heat Exchangers | Industrial Superalloy Parts

- Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy Parts

- Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy Forgings

- Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy Components

- Lork Uns N02201/ASTM B162/DIN 17740 Nickel Plate Purity Nickel 201 Alloy Sheet

- Lork Uns N07750/ASTM B637 Nickel Alloy Rod Inconel X750 Nickel Bar

- Lork Uns R31537/ASTM F1537 Cocrmo Cobalt Alloy Rod Medical Materials Cobalt-28 Chromium-6 Molybdenum Cobalt Bar

- Lork Custom AMS 5844/Uns R30035 Cobalt Rod for Aircraft Engine Fasteners MP35n Cobalt Alloy Bar

- Lork Spot Goods Uns N06200/ASTM B462 Nickel Alloy Bar Hastelloy C2000 Nickel Rod

- Hastelloy B3 N10675 Hastelloy C276 N10276 Industrial Nickel Alloy Stainless Steel Seamless Pipe Supplier

- ASTM B622 Hastelloy C276 N10276 Nickel Alloy Stainless Steel Seamless Pipe Round

- Uns N10276 Hastelloy C276 C-276 Seamless Steel Pipe / Welded Steel Pipe/Corrosion-Resistant Steel Pipe/High Temperature Resistant Steel Pipe

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Alloy > Nickel Alloy

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile