Home > Products > Plastic Mold for Automotive Industry > Custom Plastic Injection Mold for Automotive Windscreen Wipers

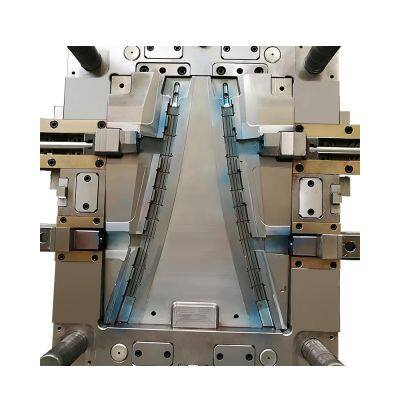

Custom Plastic Injection Mold for Automotive Windscreen Wipers

- SHENZHEN

- T/T L/C PayPal D/P Western Union Other

- 30 days

You May Like

-

Custom Plastic Mold for Automotive Control Panel

-

Custom Plastic Mold for Automotive Door Panel Multi Cavity 1+1 Family Mold

-

Custom Plastic Injection Mold for Automotive Rear Bucket

-

Custom Plastic Mold for Bluetooth Mouse Shell-Multi Cavity Injection Mould

-

Custom Plastic Injection Mold for Camera Enclosure Cold Runner Mold

-

Custom Laser Projector Plastic Injection Mold

Product Details

| Certification | TS16949, CE, ISO | Application | Car, Household Appliances, Furniture, Electronic, Home Use | |

| Standard | HASCO | Installation | Fixed | |

| Customized | Customized | Process Combination Type | Single-Process Mode | |

| Shaping Mode | Injection Mould | Surface Finish Process | Polishing | |

| Mould Cavity | Multi Cavity | Plastic Material | ABS | |

| Runner | Cold Runner | Design Software | UG |

Product Description

Website:

/plastic-mold-product/automotive-exterior-and-interior-parts

Description:

Mold Cavity | 1+1 Cav. |

Mold Steel | P20, NAK80 |

Mold Standard | HASCO |

Gate | Cold Runner |

Mold Life | 500,000 shots |

Part Material | ABS |

Plastic Injection Mold for Windscreen Wipers Mold Design

The design of automotive windshield wiper molds is a detailed and complex engineering process that involves creating precise blueprints for the production of wiper components. This design phase takes into account various factors such as material properties, the required shape and size of the wipers, the wear they will endure, and the specific demands of the automotive industry. The design must ensure that the mold can produce wipers that are not only aesthetically pleasing but also superior in functionality, with a focus on durability, flexibility, and resistance to environmental factors. Additionally, the design must adapt to the injection molding process, including plastic flow, cooling channels, and the ejection of finished parts, to ensure uniform cooling of the product during injection molding and prevent deformation and shrinkage. At the same time, the mold is designed with an adequate venting system to ensure that the final product meets the strict quality standards of the automotive industry.

Contact Us

- Shenzhen Mingjixin Technology Co., Ltd.

- Contact nameMiya Chat Now

- AddressBlock 11, Area B, Xianan Industrial Zone, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong

Product Categories

New Products

-

PMMA Lens Hot Runner multi-cavity Plastic Injection Mold

-

Custom Plastic Injection Mold for Laser Projector Shell-Injection Molding

-

Custom Plastic Mold for Industrial Fan Wheel with Parker Hydraulic Cylinder

-

Custom Plastic Injection Mold for Marine Thruster Enclosure

-

Custom PVC Plastic Mold for Threaded Pipe Fittings Multi Cavity Injection Molding

-

Custom Plastic Injection Mold for 3D Printer Housing-Injection Molding Service

-

Custom Plastic Household Mold for Coffee Pot Handles

-

Custom Plastic Mold for Hair Dryer

-

Custom Plastic Injection Mold for Router with 3C

-

Custom Plastic Injection Mold for Sweeper Housing

-

Custom Plastic Mold for TV Backplate Cover White Goods

-

Custom Overmolding/2k plastic Injection mold Two-Shot Plastic Mold

-

PET Multi Cavity Custom plastic injection mold

-

Multi Cavity Custom plastic injection mold for Switch socket plug

-

Custom Plastic Injection Mold for Automotive Drawer-Automotive Interior Trim

-

Custom Plastic Injection Mold for Automotive Hot Runner System

-

Custom Plastic Mold 1+1 Cavity Family Mold for Automotive Door Switch Panel

-

Custom Plastic Injection Mold for Automotive Lighting Multi Cavity Mould

Popular Searches

- rapid prototype

- plastic parts

- auto parts

- plastic injection

- plastic box

- injection moulding

- plastic cover

- injection mould

- Plastic Injection Mould

- Injection Molding

- Plastic Injection Molding

- Cap Mould

- plastic component

- plastic molding

- auto mould

- mould making

- Die Cast Mould

- Precision Plastic Injection Mould

- Part Injection Mould

- Shell Injection Mould

- Cover Mould

- Plastic Part Mould

- tank mould

- Bumper Mould

- Panel Mould

- Automotive Part Mould

- Automotive Injection Mould

- plastic machine

- plastic parts

- auto parts

Recommended Products

- China Injection tooling maker for plastic mould manufacture factory

- high quality Bainuo EPP foaming mould EPP foam machines for package box automotive parts

- high quality Bainuo EPP foaming mould EPP foam machines for package box autopart

- high quality Bainuo EPS foaming mould EPS foam machines for package box

- Electronic Case Mold

- Electrical Appliances Plastic Cover Mold

- 2K Injection Molding Tooling

- Die Casting Parts Mold

- Automotive Lenses Mold

- China plastic injection mould factory for Europe export usage

- epoxy resin cast mould transformer insulator manufacture APG process chinese manufacture

- Epoxy Resin Injection APG Moulding die casting mold

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Miya

Hi there! Welcome to my shop. Let me know if you have any questions.

Miya

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile