Home > Products > Plastic Mold for Automotive Industry > Custom Plastic Injection Mold for Automotive Rearview Housing Family Mold 1+1 Multi Cavity

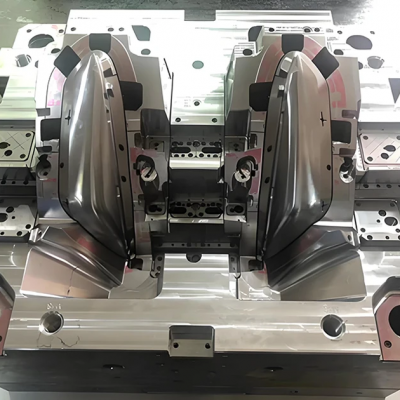

Custom Plastic Injection Mold for Automotive Rearview Housing Family Mold 1+1 Multi Cavity

- SHENZHEN

- T/T L/C PayPal D/P Western Union Other

- 30 days

You May Like

-

Custom Plastic Injection Mold for Automotive Windscreen Wipers

-

Custom Plastic Mold for Automotive Control Panel

-

Custom Plastic Mold for Automotive Door Panel Multi Cavity 1+1 Family Mold

-

Custom Plastic Injection Mold for Automotive Rear Bucket

-

Custom Plastic Mold for Bluetooth Mouse Shell-Multi Cavity Injection Mould

-

Custom Plastic Injection Mold for Camera Enclosure Cold Runner Mold

Product Details

| Certification | TS16949, ISO | Application | Car, Household Appliances, Furniture, Electronic, Home Use | |

| Standard | HASCO | Customized | Customized | |

| Process Combination Type | Single-Process Mode | Shaping Mode | Injection Mould | |

| Surface Finish Process | Polishing | Mould Cavity | Multi Cavity | |

| Plastic Material | ABS | Runner | Cold Runner | |

| Design Software | UG |

Product Description

Website:

/plastic-mold-product/automotive-exterior-and-interior-parts

Description:

Mold Cavity | 1+1 Cav. |

Mold Steel | 718H |

Mold Standard | LKM |

Gate | Cold Runner |

Mold Life | 200,000 shots |

Part Material | ABS |

Plastic Automotive Rearview Housing Mold Design

The design of the automotive rearview housing mold needs to consider the maximum outline of the plastic part as the parting surface, with an integral cavity for the upper part and an integral core for the lower part, embedded with several small inserts. The lateral part requires the design of a slider core-pulling mechanism, and the reinforced rib area of the core side needs to be designed with an angle lifter core-pulling structure. Design highlights include:

● Streamlined Surface Design: The outer surface of the automotive rearview mirror housing is a streamlined surface with a complex shape, and most other surfaces are composed of curved surfaces. This design makes the appearance more aesthetically pleasing.

● High Impact Strength and Good Appearance Characteristics: The plastic part material selected is engineering plastic ABS, which has good comprehensive performance, high impact strength, and good appearance characteristics.

● Multiple Reinforcing Rib Design: The housing contains multiple reinforcing ribs in the middle, which increases the strength and rigidity of the shell.

Contact Us

- Shenzhen Mingjixin Technology Co., Ltd.

- Contact nameMiya Chat Now

- AddressBlock 11, Area B, Xianan Industrial Zone, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong

Product Categories

New Products

-

Custom Laser Projector Plastic Injection Mold

-

PMMA Lens Hot Runner multi-cavity Plastic Injection Mold

-

Custom Plastic Injection Mold for Laser Projector Shell-Injection Molding

-

Custom Plastic Mold for Industrial Fan Wheel with Parker Hydraulic Cylinder

-

Custom Plastic Injection Mold for Marine Thruster Enclosure

-

Custom PVC Plastic Mold for Threaded Pipe Fittings Multi Cavity Injection Molding

-

Custom Plastic Injection Mold for 3D Printer Housing-Injection Molding Service

-

Custom Plastic Household Mold for Coffee Pot Handles

-

Custom Plastic Mold for Hair Dryer

-

Custom Plastic Injection Mold for Router with 3C

-

Custom Plastic Injection Mold for Sweeper Housing

-

Custom Plastic Mold for TV Backplate Cover White Goods

-

Custom Overmolding/2k plastic Injection mold Two-Shot Plastic Mold

-

PET Multi Cavity Custom plastic injection mold

-

Multi Cavity Custom plastic injection mold for Switch socket plug

-

Custom Plastic Injection Mold for Automotive Drawer-Automotive Interior Trim

-

Custom Plastic Injection Mold for Automotive Hot Runner System

-

Custom Plastic Mold 1+1 Cavity Family Mold for Automotive Door Switch Panel

Popular Searches

- plastic parts

- Plastic Injection Mould

- injection plastic mould

- Plastic Injection Molding

- Cap Mould

- Injection Molded Plastic

- Box Mould

- plastic molding

- Precision Plastic Injection Mould

- Part Injection Mould

- plastic tooling

- Injection Molding Mould

- Basket Mould

- Box Injection Mould

- chair mould

- mold making

- Cover Mould

- plastic mold part

- Pallet Mould

- electric plastic enclosure

- mold maker

- injection moulded

- plastic mold maker

- precision plastic moulds

- overmolding

- mold injection

- plastic machine

- plastic mould

- plastic parts

- control valve

Recommended Products

- China Injection tooling maker for plastic mould manufacture factory

- high quality Bainuo EPP foaming mould EPP foam machines for package box automotive parts

- high quality Bainuo EPP foaming mould EPP foam machines for package box autopart

- high quality Bainuo EPS foaming mould EPS foam machines for package box

- Electronic Case Mold

- Electrical Appliances Plastic Cover Mold

- 2K Injection Molding Tooling

- Die Casting Parts Mold

- Automotive Lenses Mold

- China plastic injection mould factory for Europe export usage

- epoxy resin cast mould transformer insulator manufacture APG process chinese manufacture

- Epoxy Resin Injection APG Moulding die casting mold

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Miya

Hi there! Welcome to my shop. Let me know if you have any questions.

Miya

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile