Home > Products > CCO Wear Plate > Custom - Made Coated Wear Resistance Steel Plate to Meet Your Specific Requirements

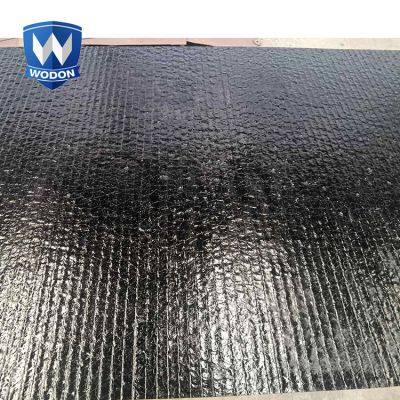

Custom - Made Coated Wear Resistance Steel Plate to Meet Your Specific Requirements

- shanghai

- T/T

- 7 days

You May Like

-

High Quality Abrasion Resistant Bimetallic Plate Hardfacing/Overlaying Wear Plate

-

factory price Wodon Super Wear-Resistant Steel Plate hardfacing alloy chromium carbide plate

-

Wodon Super Wear-Resistant Steel Plate: Built for Harsh Conditions

-

Chromium Carbide Overlay Wear for Chute/Hopper/Feeder/Bucket/Cone Liner

-

Chromium Carbide Overlay Wear/Abrasion Resistant bimetallic anti wear plate

-

Wodon super wear resistant steel plate with chromium carbide overlay

Product Details

| Brand Name | WODON | Place of Origin | China | |

| Model Number | WD1200/1500 | Length | 3000mm, 3400mm, 3500mm, customized | |

| Type | Steel Plate | Width | 1400mm, 1500mm, 2000mm, 2100mm, customized | |

| Application | Ship Plate | Surface Treatment | Coated | |

| Technique | Other, / | Standard | AISI, DIN | |

| Grade | AAA | Special Use | Wear Resistant Steel |

Product Description

high chromium alloy steel plate

What is Wodon wear plate?

Wodon wear resistant steel plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC 58~65 and depends on the overlay's thickness.

The main ingredients of Wodon plate are C (%): 3.0~5.0 and Cr (%): 25~40. This chemical proportion results in a large amount of chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles thoughout the layer will guarantee a super wear resistant surface.

The overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm, reaching up to 350 Mpa in our tests.

| Product name | Wodon high Chromium alloy abrasion resistant steel plate with high hardness |

| Material | Q235/Q345B+Chromium carbide overlay alloy |

| Certificate | ISO9001:2008 |

| Chemical composition | C: 3.0~5.0 % Cr: 25~40 % |

| Microstructure | Chromium carbide hard particles volume fraction above 50 % The maximum hardness of chromium carbide is HV 1800 |

| Wear Resistance | Our test shows that the wear resistance of Wodon plate is 30 times higher than low carbon stell and 12 times than heat treated steel |

| Impact resistance | Wodon wear plates can withstand medium impact |

| Temperature resistance | Wodon wear plates can withstand temperatures up to 600 ℃. We can customize high temperature resistance wear plates according to customer's requirements which can withstand maximum terperatures up to 900 ℃ |

| Flatness tolerance | ± 3 mm/m |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0~0.5 mm |

| Surface treatment | hardfacing, cladding, open arc or submerged arc welding |

| Standard sizes | Open arc welding: 1400*3400 mm, customized Submerged arc welding: 1400*3000 mm, 1400*3500 mm, 2100*3500 mm, customized |

The main thicknesses (mm) | 3 on 3, 4 on 4, 5 on 5 4 on 6, 5 on 6, 6 on 6, 8 on 6 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10, 20 on 10 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 10 on 12, 11 on 12, 12 on 12 6 on 14, 8 on 14, 10 on 14 6 on 16, 8 on 16, 10 on 16 6 on 18, 8 on 18, 10 on 18 5 on 20, 6 on 20, 8 on 20, 10 on 20, 20 on 20, 10 on 30, 10 on 40 Customized

|

Wodon wear plates are used to make many complex wear parts to be positioned in high wear places. We have several equipment to transform our plates: six of CNC automatic plasma cutting machine, 4 multi functional bending machines and pressing machines, with high processing capacity operated by engineers and technical experts. We can provide wear plate cutting, bending, punching and welding according to customer's drawings.

The wear resistant overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm by welding heat. In our tests are the bonding strength reaching up to 350 MPa.

The above picture shows the welding fusion line of Open arc welding(the up one) and Submerged arc welding (the down one).

Wodon wear plate are used to make many complex wear parts to be positioned in high wear places. We have several equipment to transform our plates: six sets of CNC plasma cutting machine, 4 multi functional bending machine and pressing machines, with high processing capacity operated by engineers and technical experts. We can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings.

Wodon Wear plate others

1. Chemical Composition: High carbon high chromium

2. Hardness: HRC58-65

3. Good Performance: good mechanical processing propertie to be cut, bended, punched, bolted and welded, smooth surface with uniform overlay, super wear resistance, medium impact resistance, good heat resistance.

5. Production Capacity: 90,000 square meters per year

6. Short Delivery Time: Generally 7 days according the quantity

7. We have many experienced professionals to research and develop wear plates according to customers' specified chemical compositions.

8. We can recommend proper wear plates and provide technical solutions based on working conditions.

9. on site inspection and third party inspection are available.

10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

Jiangsu Wodon Wear Resistant Material Co., Ltd is located in Jiangsu city, China's northern international shipping center. We are specialized in researching, developing and producing wear resistant products with many years experience in this field. We have more than 150 employees, with an annual output of 90,000 squaremeters of wear plates and 9000 tons of welding consumables.

Our company covers the area about 43000 square meters. And this year we are established one more branch factory in Jiangsu to improve our production capacity.The new branch factory will be finish and full function operate in June 2017 according the company's policy.

There are 3 Workshops (36000 square meter) only in Jiangsu now, after the new branch factory finished, we will have one more big Workshop in Jiangsu, so that have more place to process wear resistant work pieces like wear resistant liner, pipe and fittings and wear resistant steel plates.

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

The above picture shows our laboratory. There are many equipments to suppert our Quality Inspection Technology Department, for sample: a series of metallographic analysis equipments, protable spectrum, protable ultrasonic thickness tester, protable ultrasonic hardness tester, destop Rockwell hardness tester, Infrared carbon sulfur analyzer, Quartz sand rubber wheel abrasion test machine and Reciprocating abrasion tester.

Packaging: Steel pallet, Non fumigation pallets, plastic film, Customized

Packaging Size: customized. Loading into 20ft or 40ft Contraner.

Delivery Detail: Generally 5-15 days, it is according to quantity.

We can provide steel pallet design or product the steel pallet according to customer's drawing, so that our product can be safety surpported and easly transported with steel tape and iron ecke. We can provide our product with printing to rust protection.

Our company has a professional after-sales service team, with many years of experience not ony on hardfacing products and applications, but also on the opertion of application equipemt. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer with multiple factories, our own sales department, and inspection technology department.

Q: How long is your delivery time?

A: Generally 5 - 10 days if in stock, 15 - 20 days if not, depending on quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, free samples are available.

Q: What are your terms of payment?

A: 30% T/T in advance, balance against copy of BL. FOB, CIF, CFR terms are all available.

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company\'s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.?

Contact Us

- Jiangsu Wodon Wear Resistant New Material Co., Ltd.

- Contact namezhang Chat Now

- AddressNo. 888, Kaituo Road, Hongze Economic Development Zone, Huaian, Jiangsu

Product Categories

| Ungrouped | CCO Wear Plate | Flux Core Welding Wire | Wear Components |

| Wear Pipes and Fittings | Wear parts |

New Products

-

High Chromium Carbide Overlay Plate Liner Plate Wear Resistant Steel Plate

-

Factory Direct Wear-Resistant Welding Wire Flux Cored Welding Wire

-

Self-shielded Flux-cored Welding Wire Mig Welding Accessories For Soldering

-

High Quality Customized Diameter Gas Protection Copper Coated Welding Wires

-

flux cored repairing welding wire mig carbide chrome cement squeeze roller and steel mill roller

-

Wodon Wear-Resistant High Alloy Steel Welding Wire

-

Overlay Hardfacing Flux Cored Welding Wire for Cement Squeeze Roller & Steel Mill Roller Metal & Metal Products Repairing

-

Factory direct sales welding wire roller Abrasion-Resistant Flux Core Wire

-

OEM Industrial Equipment Flux Cored Welding Wire Shielded Gas Welding Wires at Low Prices

-

High Quality China Manufacture Roller Rebuilding Hardfacing Welding Wires

-

High Quality Continuous Casting Roller Hardfacing Welding Wire

-

Abrasive Submerged Arc Self Shielding Flux Cored Hardfacing Welding Wire

-

Hardfacing Soldering Wire High Temperature Flux Cored Welding Wire

-

Gas shielded flux-cored wire Stainless steel low temperature steel electrode welding wire

-

Hard-faced wear-resistant self-protecting wire flux-cored welding material

-

China Factory High Temperature Resistant Flux Core Wire for Hardfacing Welding Wires

-

Cost Effective Wear Resistant Hardfacing Cladding Die Flux Cored Welding Wire

-

Wear Resistant Flux Cored Welding Wire for Buffer/Surfacing Hot Roller Layer

-

Welding material wear-resistant wire manufacturers Tungsten carbide high alloy flux-cored welding wire

-

High hardness alloy material for surfacing flux-cored wire

-

Gas protection wear-resistant drug core valve impeller paper machine surfacing welding wire

-

Wear-resistant cored wire high hardness surfacing all kinds of wear parts surface

-

Hardfacing Wear Resistant Nickel Welding Wire Flux Cored Welding Wire

-

Super wear resistant Gas shielded surfacing wear-resistant cored wire

Popular Searches

- steel billet

- hot rolled

- carbon steel plate

- steel plank

- stainless steel plate

- ceramic plate

- steel plate

- steel sheet

- steel circle

- ship steel plate

- jaw plate

- steel sheet plate

- alloy steel plate

- x120mn12

- manganese steel plate

- manganese steel

- lining plate

- carbon plate

- steel roll

- side plate

- steel disc

- mill liner plate

- mould steel plate

- composite steel plate

- manganese plate

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Sheet & Plate

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile