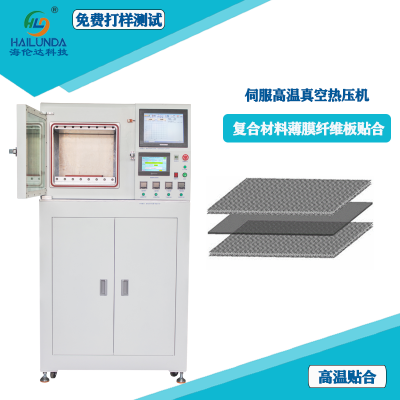

Home > Products > High temperature vacuum hot pressing bonding machine > Servo high temperature vacuum hot press Electric cylinder high pressure and high precision vacuum press 450 degrees Celsius, 5 tons, 10 tons

Servo high temperature vacuum hot press Electric cylinder high pressure and high precision vacuum press 450 degrees Celsius, 5 tons, 10 tons

- shenzhen/guangzhou/YIWU

- T/T Other

- 40 days

You May Like

-

FOG Small size Flex Cable Hot Pulse Heating Mini ACF FOF TAB Bonding Machine for LCD LED Screen Repair

-

High temperature vacuum hot press in university laboratory High temperature material hot press manufacturer

-

Final bongding machine Anisotropic Conductive Film ACF FPC PCB silicon wafer hot press welding machine Equipment manufacturer

-

FPC soldering machine Pulse Hotbar welding machine Servo precision PCB board welding and wiring operation Machine manufacturer

-

Hotbar welding machine shenzhen Hailunda Pulse soldering machine PCB board and FPC hot press

-

Shenzhen Hailunda Vacuum laminator equipment manufacturer 14 years factory Coating defoaming machine

Product Description

1, product use (for the need for high temperature, high pressure, high precision pressure products, suitable for university research institute, laboratory research and development, large-scale factory mass production and other equipment needs)

(1) Suitable for high temperature hot pressing of new material industry related products, and suitable for liquid fitting of SCA/OCA adhesive process products

Crystal, TP/LCM and polymer materials COP, COC,PMMA, PC and other hot pressing bonding;

(2) Suitable for plastic/glass/metal parts and special materials, new energy industry parts, aviation parts, chip/circuit board, electronic plug-in parts, etc.

(3) and the fixture can be placed in the corresponding position between the workpiece to be fitted. By manually moving the product to the working platform to vacuum, hot pressing, pressure preservation.

2, the machine features

(1) Pressure control: the pressure sensor is used to set the pressing force of the servo and its detection force value, and the position sensor is used to set the upper limit position, origin position, pressing position and lower limit position of the servo, and the pressing position can be automatically detected and saved to the corresponding formula through the preset pressing force;

(2) Temperature control: the upper and lower plate constant temperature heating mode is adopted, and the temperature control PID algorithm is used to automatically and accurately control the heating;

(3) Process control: 30 product formulas can be stored in process storage, and the working parameters required by the current press can be retrieved by entering the formula number; At each stage of equipment operation, the touch screen will have the corresponding text information display, and the change of the relationship between the pressing force and time is depicted in the real-time dynamic curve display in the man-machine interface;

(4) Data storage: it can store the historical data of displacement and pressure during the press assembly process, and automatically convert the data into excel files directly uploaded to the host computer for storage (or U disk), which can be used for daily query and printing; The touch screen can directly save the historical alarm information of the device (within 90 days), and can also be uploaded to the host computer storage (or U disk) as a basis for daily equipment maintenance;

(5) Safety protection: the electrical system is equipped with thermal overload protection switch, leakage protection switch power supply, grating protection, emergency stop button and three-color light buzzer;

(6) Alarm warning: 1, the self-check pressure data unqualified and abnormal operation alarm, 2, the pressure exceeds the maximum value or the pressure position is not immediately issued a buzzer alarm, 3, the heating pressure plate temperature is not up to the set value of the operation of the buzzer alarm immediately, 4, the safety grating during the operation of the equipment to detect any abnormal object in the shooting area immediately alarm, 5. In case of emergency during the operation of the equipment, you can press the emergency stop and return to the standby state;

(7) Vacuum mode: According to the actual needs of the product can be selected with vacuum pressure mode/no vacuum pressure mode;

(8) Automatic state: when starting up, the device automatically finds the mechanical origin, after setting the parameters, press the start button with both hands, and the indenter will decrease the fast forward speed near the product, and then decrease the contact with the product surface at the buffer speed, and then stop the pressure until the pressure holding time reaches the end of the process.

Contact Us

- Shenzhen Hailunda Technology Co.,LTD

- Contact nameJoe Chat Now

- Phone86-13684976583

- AddressFloor 3, building 3, huixin intelligent industrial park, lianteng road, guangming new district, shenzhen, China, Shenzhen, Guangdong

Product Categories

New Products

-

300 degrees high temperature vacuum hot press High temperature experimental machine for new material development

-

Shenzhen Hailunda 500X700mm OCA vacuum laminator 40mm use height Open tool operation 100 degrees operating temperature

-

Double head soldering machine PCBA motherboard automatic soldering machine TWS headphone welding machine

-

Servo vacuum hot press machine for high-pressure and high-temperature laboratory use hot press machine Vacuum New material laminating machine

-

High Precision Hot Pressing Machine for CBC PC COP Resin Part Rigid Chips Bonding Machine Servo vacuum hot press machine Precise pressure control

-

Hailunda GZC-TF21 vaccum laminating machine Model Large size laminating machine

-

GZC-YPJ09 Pulse hot press machine for screen assemble electronic production FFC, FPC ACF bonding solderging to FPC and PCB

-

GZC-TF16 LCD screen repair refurbished OCA vacuum laminating debubble bubble remove machine for 16

-

HAILUNDA GZC-MY200E Pulse hot press machine for screen assemble electronic production FFC, FPC ACF New LCD Flex Cable Repair Machine ACF Bonding

-

Japanese special welding machine for printing head of ceramic parts Pulse thermocompression welding machine Special equipment for ceramic process

-

GZC-TF16 Factory 2024 new product 16-inch vacuum laminating machine

-

HAILUNDA GZC-MY200E lcd panel flex cable repair machine pressing machine phone screen machine lcd flex cable repair machine

-

Double-station rotary soldering machine GZC-MY300 Pulse welding machine PCB with FFC, FPC, LCD, goldfinger, zebra paper welding process

-

GZC-MY200E mobile phone repairing machines hot press machine lcd repair machine flex cable bonding machine

-

27 inch integrated computer LCD screen replacement laminating equipment 30 inch OCA vacuum laminating machine

-

GZC-COF280 High precision line pulse pressing machine Mobile phone wiring maintenance machine

-

Hailunda21 inch laminating equipment is used for auto central control panel laminating 15.6

-

ACF 7813 7206 7106 2056 conductive adhesives are available in different length specifications

-

Pulse pressing machine with knife head apple pressure touch LCD Samsung general knife head professional custom knife head

-

FFC FPC welding machine FPC flexible wire welding equipment Circuit board hot press machine LCD hot pressing machine

-

GZC-TF21 LCD screen repair refurbished OCA vacuum laminating debubble bubble remove machine for 16

-

200 degree high temperature vacuum hot pressing machine mainly used for chip vacuum hot pressing

-

HAILUNDA 30 inch OCA vacuum laminating machine Hot melt adhesive vacuum laminating machine

-

Double position soldering machine FPC welding machine Haba welding equipment

Popular Searches

- testing machine

- lab instrument

- laboratory equipment

- test chamber

- testing instrument

- vacuum bag

- vacuum drying oven

- vacuum hose

- muffle furnace

- tube furnace

- vacuum furnace

- vacuum tube furnace

- environmental chamber

- heat treatment furnace

- box furnace

- vacuum chamber

- lab oven testing

- vacuum oven

- vacuum sintering furnace

- brazing furnace

- vacuum atmosphere furnace

- vacuum drying

- vacuum oven equipment

- high temperature lab oven

- vacuum cabinet

- temperature vacuum drying oven

Recommended Products

- UFC762AE101 3BHE006412R0101 Control System DCS Spare Parts Spot Goods

- DSMB-01C Spare Parts of Inverter Power Boards for Frequency Converters Fast Delivery Power

- RS-FS-9001 362A1052P404 Spiral Joint Fluid Control System

- Vibro-meter VM600 RPS6U 200-582-200-011 Vibration Sensor Detection System

- TRICONEX 4351B Control Module

- FOXBORO FCP270 P0917YZ Controller Module

- H201Ti Monitor Industrial Control DCS System

- UNITROL 1020 UNS0119A-Z V1 3BHE030579R0003 Excitation Static Controller

- Vibro-meter 200-560-000-018 200-560-101-015 VM600 IOC4T Module/Controller

- EMERSON VE3008 CE3008 KJ2005X1-MQ1 12P6381X042 Industrial Automation System Module

- ALSTOM N897164624A Module/controller Redundancy Positioning System

- ALSTOM N895314513L Data Acquisition Module

Find Similar Products By Category

- Electrical & Electronics > Power Transmission & Transformer > Transformer

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Joe

Hi there! Welcome to my shop. Let me know if you have any questions.

Joe

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile