Home > Products > Carbonization machine > Biomass charcoal making machine for sale

Biomass charcoal making machine for sale

- Qingdao Port

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 30 days

You May Like

-

Solar panel recycling machine with high efficiency

-

Coconut shell charcoal making machine

-

Photovoltaic solar panels recycling plant

-

Lithium Ion Battery Recycling Machine For Black Mass And Metal

-

Stable performance computer Board Recycling Machine

-

DOING supply photovoltaic solar panels recycling machine

Product Details

| Brand Name | Henan Doing | Place of Origin | China | |

| Warranty | 1 year | Condition | New |

Product Description

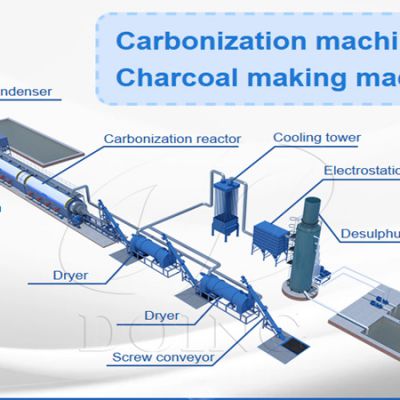

Charcoal making machine is an environmental protection type machinery, also called carbanization furnace. The charcoal making machine is used to convert biomass wastes such as wood chips, bamboo, coconut shells, sawdust, rice husks and many agricultural wastes into high-quality charcoal.

DOING charcoal making machine uses pyrolysis technology to convert biomass waste into charcoal under anaerobic and high-temperature conditions. Next, I will take wood as an example to introduce the working process of DOING charcoal making machine.

Charcoal making machine

The working process of the charcoal machine is to pyrolyze wood at high temperatures, remove moisture, volatile matter and ash in the wood, and finally obtain charcoal. The working process of charcoal making machine is generally divided into three main stages: drying, carbonization and cooling.

1.Drying:Drying is the first step in the working process of charcoal making machine. First, start the carbonization furnace and heat the air in the furnace by burning a certain amount of fuel (such as charcoal, coal, etc.) to gradually increase the temperature in the furnace and preheat the raw materials. This step is used to dry the raw materials, evaporate moisture and other volatile substances in the raw materials, and reduce gas emissions during the carbonization process.

Dryer of charcoal making machine

The raw materials contain moisture and volatile organic compounds, which need to be dried and devolatilized. Drying temperature and time vary depending on the raw materials. Therefore, in specific practice, parameters such as heating temperature and holding time need to be adjusted according to the characteristics of the raw materials and the requirements of the target product to obtain the best carbonization effect. For example, raw materials such as wood generally need to be dried first to reduce the moisture content to less than 10%.

2.Carbonization:When the furnace temperature reaches a certain level, the volatile organic compounds in the raw materials begin to decompose, producing some flammable gases (such as methane, carbon monoxide, etc.). At the same time, the solid part of the raw materials begins to undergo a carbonization reaction, eventually forming carbon. Carbonization is the focus of the working process of charcoal making machine and require more attention. During this process, some parameters such as temperature, carbonization speed, etc. need to be paid attention to and controlled to ensure the quality of the carbonized product.

Carbanization of charcoal making machine

3.Cooling:Place the carbonized charcoal in a well-ventilated place for cooling so that the charcoal gradually cools down. During the cooling process, the charcoal shrinks and forms a hard structure, allowing it to achieve high carbon content and excellent physical and chemical properties. If you want to collect by-products such as tar and wood vinegar, you can configure a more comprehensive production line.

Although the working process of charcoal making machine is relatively simple, the high performance, sustainability and economic viability of charcoal making machine plays a key role in sustainable resource utilization and circular economy strategies.

The advantages of DOING charcoal making machine are as follows:1.It has high production efficiency and stability, and can continuously produce high-quality charcoal fuel to meet market demand, the carbonization rate can reach 99%.

2.Wide range of raw material adaptability, saving time.

3.Equipped with exhaust gas treatment system, the working process of charcoal making machine is environmental protection.

4.The combustible gas generated during carbonization process can be recycled as fuel in the furnace after purification, greatly reduce energy consumption and emissions.

5.Charcoal making machine adopts PLC control system and automation technology, which is easy to operate and has low labor cost.

DOING has more than thirteen years of professional knowledge, focusing on waste recycling machinery. So if you want to know more about charcoal making machine, or want to carry out similar projects, please feel free to contact the DOING.

Contact Us

- Henan Doing Environmental Protection Technology Co., Ltd

- Contact nameVivien Chat Now

- AddressJinshui strict, Zhengzhou, Henan

Product Categories

New Products

-

Continuous carbonization machine for charcoal making

-

Cylindrical lithium battery recycling machine

-

DOING photovoltaic solar panels recycling production line

-

Radiator Crushed And Separation Machine

-

Factory Delivery lithium battery recycling machine

-

Large Scale Continuous Charcoal Making Machine

-

PV Solar Panel Crushing And Separation Machine

-

Lithium ion battery recycling plant cost in india

-

Biomass Pyrolysis Plant For Charcoal Making

-

Medical blister aluminum plastic separation machine

-

Scrap Circuit Board Recycling Machine For Copper Extracting

-

Lithium-ion Battery Metal And Black Mass Recycling Plant

-

Photovoltaic solar panels Frame Glass recycling production machine

-

Radiator Disposal And Recycling Machine

-

Continuous Rotary Wood Sawdust Carbonization Furnace to BBQ

-

ACP aluminum plastic separation machine

-

Efficiency Disposal Lithium battery recycling machine

-

Manufacturer Provide Scrap Electronic Waste Recycling Machine For Metal Recovery

-

Photovoltaic solar panels Frame Glass recycling production machine

-

Cable Wire Granulator Machine For Copper And Plastic Separating

-

Plastic Coated Aluminum Materials Recycling Separator

-

Mobile phone lithium ion battery recycling machine

-

Printed circuit board recycling machine with 99% separating rate

-

High Efficiency Carbonization Machine For Charcoal Production

Popular Searches

- Paper Bag Making Machine

- briquette machine

- briquette press

- Pressing Machine

- Wood Pellet Mill

- briquette

- briquette making machine

- Tablet Making Machine

- Charcoal Briquette Machine

- Charcoal Briquette Making Machine

- Ball Press Machine

- Charcoal Packing Machine

- Wood Charcoal Making Machine

- coal briquette making machine

- sawdust dryer

- Wood Hammer Mill

- rod making machine

- Briquetting Making Machine

- carbonization furnace

- biomass briquette

- carbonization stove

- sawdust briquetting presses

- charcoal extruder

- Furnace Machine

- milling machine

- recycling machine

- recycling

- Rotary Furnace

- Charcoal Making Machine

- sawdust briquette

Recommended Products

- Biomass to Biochar Pyrolysis Machine - Automatic Charcoal Making Machine for Wood/Coconut Shell/Agriculture Waste

- Biochar Pyrolysis Machine | Carbonization Furnace for Wood/Coconut Shell/Rice Husk

- Biochar pyrolysis plant | High yield carbonization furnace for charcoal

- Kawise Biomass Pellet Machine – High-Efficiency Pelletizing Solution

- Charcoal Production Machinery for Coconut Shell/Wood/Biomass Briquette Production

- Flat Die Biomass Pellet Mill – Turn Waste into Clean Energy

- Charcoal Briquette Press Machine Converts Sawdust/Coconut Shell/Rice Husk/Wood Into Charcoal

- Maximize Efficiency with the Kawise Small Pellet Machine

- The Growing Demand for Biomass Pellets and the Role of Biomass Pellet Machines

- Maximize Efficiency with a PTO-Driven Pellet Mill for Feed & Biomass Production

- Enhance Your Production Efficiency with Our Diesel Pellet Mill

- Choosing the Right Raw Materials for Biomass Pellet Production

Find Similar Products By Category

- Manufacturing & Processing Machinery > Woodworking Machinery > Wood Pellet Mill

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Vivien

Hi there! Welcome to my shop. Let me know if you have any questions.

Vivien

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile