Home > Products > stainless steel filter > Titanium expanded wire mesh for filtration and battery electrode

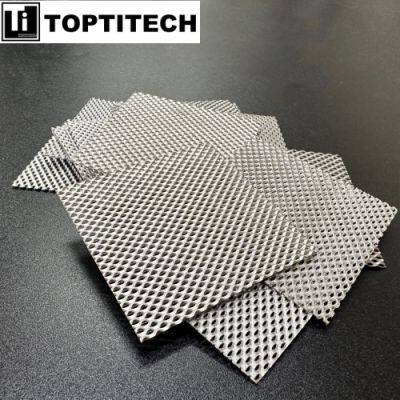

Titanium expanded wire mesh for filtration and battery electrode

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

-

Microporous Pure Titanium Aeration Head For Sewage Treatment

-

1mm Thickness Single-layer Stainless Steel Wire Mesh Filter Disc

-

Customized connector pleated sintered filter cartridges

-

Sintered Metal Powder Filter Cartridges

-

Threaded Metal Wire Mesh Filter Single Open End

-

30 inch 5 micron 226/Fin adpator SS316L filter cartridge

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | TW-02 | Application | filtration,ozone diffusion filter,water treatment | |

| Technique | Sintered | Grade | stainless steel wire mesh | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

Titanium expanded mesh, also known as titanium mesh or titanium expanded metal, is a type of mesh-like material made from titanium. It is created by expanding a sheet of titanium through a process known as "expanding," which involves cutting and stretching the metal to form a pattern of interconnected diamond-shaped openings.

The expanded wire is lightweight, strong, and corrosion-resistant due to the inherent properties of titanium. It offers excellent durability and can withstand high temperatures, making it suitable for various applications in industries such as aerospace, automotive, chemical processing, filtration, and architecture.

Parameters

Hole type: diamond hole

Plate thickness: 1mm

Filtration precision: 200 microns

Material: titanium plate

Purpose: Filtration, electrolysis and hydrogen production

Aperture: 1*2mm

Applications

Filtration: Titanium mesh is often used in filtration systems, particularly in applications where high strength and corrosion resistance are required. It can be used to filter liquids, gases, or even solid particles.

Battery electrodes: Titanium expanded wire can be employed as a current collector or electrode material in batteries. Its high conductivity and resistance to corrosion make it a suitable choice for battery applications.

Architectural applications: Titanium mesh can be used in architectural projects to create unique designs and decorative elements. It provides a visually appealing appearance while offering durability and weather resistance.

Heat exchangers: Due to its excellent thermal conductivity, titanium expanded wire can be used in heat exchangers to transfer heat efficiently. It is particularly useful in corrosive environments where other metals may degrade.

Medical implants: Titanium mesh is also used in the medical field for various applications, including orthopedic implants and reconstructive surgeries. Its biocompatibility, strength, and resistance to corrosion make it a preferred material for implantable devices.

The process of expanding titanium to create the mesh

Material selection: The first step is selecting the appropriate grade of titanium for the desired application. Titanium alloys, such as Ti-6Al-4V (Grade 5), are commonly used due to their high strength and corrosion resistance.

Perforation: A flat sheet or plate of titanium is perforated with a pattern of holes. These holes can be created using various methods, including punching, laser cutting, or chemical etching. The hole size, spacing, and pattern can be customized based on the specific requirements of the mesh.

Expansion: The perforated titanium sheet is then fed into an expanding machine. The machine consists of a series of rollers that stretch the sheet in both length and width directions simultaneously. As the sheet passes through the rollers, the material is elongated, causing the holes to expand and the flat sheet to transform into a three-dimensional mesh structure.

Diamond-shaped openings: The stretching process results in the formation of diamond-shaped openings in the titanium mesh. The size and shape of these openings depend on the design of the expanding machine and the specific parameters used during the process.

Flattening and trimming: After the expansion, the titanium mesh may undergo additional treatments to flatten the surface and remove any irregularities. Trimming may also be performed to achieve the desired final dimensions and shape.

Cleaning and inspection: The expanded titanium mesh is thoroughly cleaned to remove any debris or contaminants that may have accumulated during the manufacturing process. It is then inspected for quality assurance, ensuring that it meets the required specifications and standards.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

Stainless steel solvent suction filter head inlet filter HPLC liquid chromatography consumables

-

0.45um Sintered Stainless Steel Powder Porous Ozone Diffuser

-

0.5 micron sintered microporous filter tube for water treatment

-

480MM DOE Stainless Steel Pleated Filter Cartridge For Oil Filtration

-

30" SUS 316L Sintered Alloy Porous Filter Elements

-

40'' KF63 interface porous SS316L candle filter tube

-

Sintered stainless steel 304/316L wire mesh filter pipe

-

Multilayer Wire Mesh Filter Stainless Steel

-

1micron Porous Metal Filter Tube for Oxygen Distributor

-

Square porous titanium plates for fuel cell

-

5 micron M10 thread air muffler sintered stainless steel

-

100 Microns porous 304 316L SS stainless steel sintered wire mesh filter disc

-

Square Porous Titanium Plate With Hole for Gas Diffusion Layer

-

30um Flange Connection Porous Titanium Filter Separation Element

-

Multilayer Sintered Stainless steel Wire Mesh Filter tube

-

1 Micron customized Sintered SS Wire Mesh Filter Disc

-

Sintered Porous Copper Filter for Gas Vent in Vacuum Mold

-

Multi-layered diffusion-bonded stainless steel mesh

-

50-80% pure Nickel fiber felt for fuel cell

-

Five layer sintered stainless steel wire mesh filter tubes for petroleum and chemical industries

-

Titanium Disc Aerator for water treatment

-

Micron SFT01 SFT02 Oxygen Diffusion Stone Aeration For Beer Wine Tools Bar Accessories

-

Porous Metal Gas/Liquid Injector Spargers

-

Titanium Disc Aerator for Wastewater Treatment Plants

Popular Searches

- Filter Element

- fuel filter

- Woven Wire Mesh

- Oil Filter Element

- Hydraulic Oil Filter

- galvanized wire mesh

- hydraulic filter

- air filter element

- Hydraulic Filter Element

- Screen Pipe

- Cartridge Filter Element

- Filter Disc

- Glass Fiber Filter

- stainless steel filter disc

- wedge wire filter element

- Epoxy Coated Wire Mesh

- Cylinder Filter Element

- hydraulic filter replacement

- vickers filter

- lube oil filter element

- hydraulic filter cross reference

- hydraulic suction filter

- internormen filter element

- wire mesh filter cartridge

- wire mesh hydraulic filter

- wire mesh oil filter

- filter cartridge

- Filter Element

- wire netting

- garden fence

Recommended Products

- Manufacturers sell welding grade rutile sand

- 95% Rutile sand for welding electrodes

- 95% rutile sand, specifically used for welding electrodes.

- 95% rutile sand, specifically used for welding electrodes.

- 95% Rutile sand for welding electrodes

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- High purity 95% rutile sand

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- Petrochemical oil storage tank barrier explosion-proof material for gas stations, with a wide range of applications

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile