Home > Products > stainless steel filter > 100 Microns porous 304 316L SS stainless steel sintered wire mesh filter disc

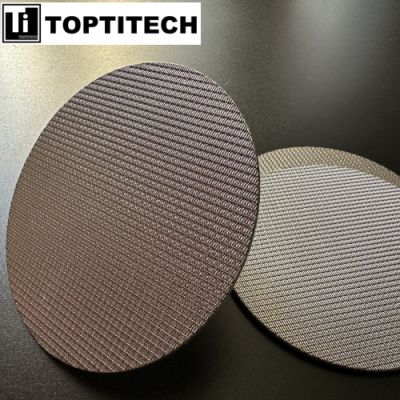

100 Microns porous 304 316L SS stainless steel sintered wire mesh filter disc

- 30000000 Piece / Pieces per Month

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

-

Square Porous Titanium Plate With Hole for Gas Diffusion Layer

-

30um Flange Connection Porous Titanium Filter Separation Element

-

Multilayer Sintered Stainless steel Wire Mesh Filter tube

-

1 Micron customized Sintered SS Wire Mesh Filter Disc

-

Sintered Porous Copper Filter for Gas Vent in Vacuum Mold

-

Multi-layered diffusion-bonded stainless steel mesh

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | SSW-08 | Application | filtration,ozone diffusion filter,water treatment | |

| Technique | Sintered | Grade | Stainless steel powder | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

The stainless steel sintered mesh is a novel filtration material created through the utilization of multiple layers of woven metal wire, employing specialized stacking and vacuum sintering processes, thereby manifesting superior mechanical strength and structural integrity.

Characterized by its microporous structure, this sintered mesh features uniformly distributed minute pores across the entire mesh material. This micro-pore configuration enables efficient filtration of minute particles, impurities, solid particles, and other undesired substances present in liquids or gases. Leveraging the corrosion resistance and high-temperature durability of stainless steel, this sintered mesh exhibits commendable chemical stability and robustness, rendering it suitable for diverse and harsh environments, including high-temperature and high-pressure conditions encountered in filtration operations.

Characteristics:

High Mechanical Strength and Pressure Resistance: Possesses remarkable mechanical strength and pressure resistance. Exhibits excellent processing, welding, and assembly properties, ensuring ease of use.

Filtration Layer Protection and Uniformity: Positioned as the second layer within the structure, ensuring effective protection and diversion for superior filtration accuracy and uniform performance. Ensures high stability.

Stainless Steel Material Selection: Utilizes stainless steel material renowned for its excellent corrosion resistance and heat resistance, suitable for filtration within a temperature range of -200°C to 480°C and in acidic or alkaline environments.

Surface Filtration Structure for Backwashing: Employs a surface filtration structure for backwashing, enabling exceptional backwash cleaning effects, reusability, and an extended lifespan. (Backwashing methods include counterflow water, filtrate, ultrasonic, fusion, and baking techniques for cleaning.)

Formation process of sintered mesh structure:

Material Preparation: Selection of metal mesh with varying particle sizes or pore diameters as raw materials, typically arranged in a five-layer structure comprising protective, filtering control, dispersing, supporting skeleton, and skeleton layers. These metal mesh pieces are usually made of high-quality stainless steel such as 304 or 316L, possessing characteristics of high temperature resistance and corrosion resistance.

Layer Stacking: Layering and arranging multiple layers of metal mesh with different particle sizes or pore diameters according to design requirements to form a multi-layered structure.

Sintering Process: Placing the stacked metal mesh pieces into a sintering furnace or applying sintering techniques for treatment. At elevated temperatures, the intersection points of the metal mesh pieces are sintered together, forming a robust and durable integrated structure. Sintering temperature and duration are controlled based on material properties and desired final performance.

Pressure Treatment: After sintering, the five-layer sintered mesh undergoes pressure treatment. Applying specific pressure ensures more secure bonding between layers, enhancing stability and durability.

The five-layer sintered mesh is comprised of multiple layers of metal mesh pieces, each with different pore sizes or diameters, resulting in higher filtration precision and better filtering performance. This structure caters to various particle size filtration requirements and finds widespread application in liquid or gas filtration processes in industries such as chemical, pharmaceutical, and food processing.

What are the advantages of a five-layer sintered mesh compared to traditional single or double-layer sintered mesh?

Compared to traditional single or double-layer sintered mesh, the five-layer sintered mesh exhibits several innovative aspects and advantages in both structure and performance:

Enhanced Filtration Precision with Multi-layer Structure: The five-layer sintered mesh employs a multi-layer stacking design wherein each layer can feature different pore sizes or diameters. This capability allows for more effective filtration of diverse sizes and types of impurities or particles, thereby elevating precision and filtration effectiveness.

Augmented Mechanical Strength and Pressure Resistance: The multi-layer structure enhances the durability of the sintered mesh. The solid interconnection among layers, achieved through sintering, boosts the sintered mesh's mechanical strength and ability to withstand pressure, making it more suitable for high-pressure or heavy-duty filtration tasks.

Flexibility and Customized Design: The production process of the five-layer sintered mesh permits adjustments in different layer levels concerning mesh piece diameters or pore sizes, catering to specific filtration needs. This customized design and flexibility enable the sintered mesh to better adapt to diverse industry requirements and application scenarios.

Higher Filtration Efficiency and Capacity: The multi-layer structure provides an expanded filtration surface area, increasing the filter's capacity and efficiency. This results in a higher volume of liquid or gas passing through effectively filtered, reducing the frequency of filter replacements and enhancing the filter's lifespan.

In summary, the innovative aspect of the five-layer sintered mesh lies in its multi-layered structural design, enabling more efficient and precise filtration through layered mesh pieces. Its heightened pressure resistance and applicability render it a crucial filtration material in numerous industrial fields.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

50-80% pure Nickel fiber felt for fuel cell

-

Five layer sintered stainless steel wire mesh filter tubes for petroleum and chemical industries

-

Titanium Disc Aerator for water treatment

-

Micron SFT01 SFT02 Oxygen Diffusion Stone Aeration For Beer Wine Tools Bar Accessories

-

Porous Metal Gas/Liquid Injector Spargers

-

Titanium Disc Aerator for Wastewater Treatment Plants

-

0.1mm Ultra-Thin Titanium Porous Transfer Layer For PEM Electrolysers

-

1.4mm Thickness Multi-layer (3 layers) Titanium Mesh for Electrolyzer

-

1500mm length stainless steel powder sintered filter tube

-

Double-frame Layer Stainless Steel 316 Pleated Filter Cartridge

-

100 microns Sintered Titanium Filter Cartridge

-

Titanium Expanded Mesh for PEM Electrolyzers

-

1.0mm GR1 Brushed Titanium Plate

-

0.4mm To 1.0mm Stainless Steel Fiber Felt For Filtration Industry

-

SS316L Perforated Mesh Wire Mesh Combination Filter Barrel

-

DOE 1000mm Stainless steel pleated Mesh filters Cartridge

-

Titanium rod filter elements are used for water filtration after ozone disinfection

-

DOE 60mm Stainless Steel Wire Mesh Pleated Cartridges

-

Sintered stainless steel filters as carbonation stone for beer

-

Platinum coated titanium bipolar plates for PEM production hydrogen

-

1micron 316L Microporous Air Diffuser with 40NB Connector

-

5mm Sintered stainless steel Multi-Layer Wire Mesh Laminated plate

-

M20 15um Sintered Metal Porous Titanium Gas Sparger/Diffuser

-

0.1 micron porous stainless steel capillary tube filter

Popular Searches

- water filter

- Filter Element

- Filter Wire Mesh

- Stainless Steel Wire Mesh

- filter mesh

- Stainless Steel Filter

- Liquid Filter

- metal filter element

- stainless steel filter disc

- Stainless Steel Disc

- porous metal

- porous stainless steel

- Filter Mesh Disc

- stainless steel filter screen

- Metal Powder Filter

- mesh disc

- mesh filter disc

- stainless steel micron filter

- filter pieces

- Filter Disc Cartridge

- auto parts

- air filter

- exhaust muffler

- silencer

- pneumatic components

- pneumatic fitting

- pneumatic silencer

- Silencer Muffler

- Pneumatic Muffler

- filter component

Recommended Products

- 10 microns Nickel Powder Wire Mesh Composite Porous Plate

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- SUS304 Sintered Multilayer Wire Mesh Filter for Cooling Water Filtration

- Large Capacity 12 tubes 9200Nm3 CNG tube trailer for gas transporting in medium or long distance.

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- Sintered Porous Polyethylene (PE) Filter With Strong Acid Resistance

- Natural rutile sand for sale

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Karry

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Karry

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile