- Henan Xinhongji Refractory Material Co. Ltd.

-

Zhengzhou, Henan, China

- Main products: Refractory bricks, refractory castable, High alumina bricks, Mullite bricks, High Alumina Castable, Magnesia bricks, Refractory fire clay bricks, Silica mullite bricks, Calcined Kaolin, ceramic balls, Honeycomb ceramic regenerators, Bauxite

Home > Products > Refractory Bricks > High Heat Conductivity Silicate Bonded SiC Refractories Silicon Carbide Refractory Bricks

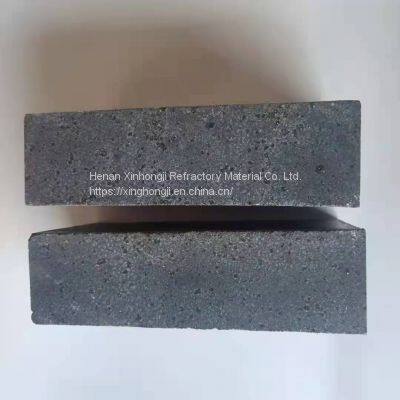

High Heat Conductivity Silicate Bonded SiC Refractories Silicon Carbide Refractory Bricks

- 10000 Ton / Tons per Month

- Tianjin/Qingdao

- T/T L/C Cash

- 10 days

You May Like

-

Professional Fireclay Brick Low Creep Refractory Thermal Insulation Fire Clay Bricks

-

High Wear Resistance General Fireclay Blocks Thermal Insulation Fire Clay Refractory Bricks

-

High Temperature Thermal Insulation Calcined Alumina Magnesia Spinel Anti-peeling Refractory Castables

-

High Thermal Thock Stability Magnesite Aluminate Refractory Blocks Magnesia Alumina Spinel Firebricks

-

High Heat Spalling Resistance Magnesia Hercynite Firebricks Magnesia Iron Alumina Spinel Bricks

-

High Density Alumina Thermal Insulation Sphere Ball Heat Storage Refractory Ceramic Balls

Product Details

| Brand Name | Xinhongji Refractory | Place of Origin | China | |

| Model Number | NHJ-202C010 | Shape | Powder | |

| Material | Castable | CaO Content (%) | 1 | |

| MgO Content (%) | 1 | SiC Content (%) | 90~99 | |

| Refractoriness (Degree) | 1770°< Refractoriness< 2000° |

Product Description

Silicon Carbide Bricks

Introduction

Silicon Carbide Bricks, (also be called silicon carbide refractory brick or silicon carbide firebrick) are a kind of refractory materials made of SiC as the main raw material. The silicon carbide content is from 72% to 99%. Generally, black silicon carbide (SiC content above 96%) is used as the raw material, and the binder (or no binder) is added, and then it is prepared by batching, mixing, molding and firing. The main crystal phase is silicon carbide. Silicon carbide refractories are mainly divided into several types of clay bonding, Si3N4 bonding, Sialon bonding, β-SiC bonding, Si2ON2 bonding and recrystallization. It is stable to acidic slag and has good wear resistance, corrosion resistance, high temperature strength, good thermal shock stability, high thermal conductivity, and low thermal expansion coefficient. They are high-performance refractory materials.

The silicon carbide brick is made of black SiC raw material. The main crystal phase is SiC. The silicon carbide brick is formed by matching the binding agent, mixing, molding and firing process. The moth hardness of silicon carbide brick is 9.

The silicon carbide castables do not weaken on heating and display superior operational properties: the compressive strength is 40–80 MPa at sintering temperature 400°C and 50–85 MPa at 1300°C, the strain onset temperature under a load of 0.2 MPa is 1700–1510°C; thermal stability (1300°C - water) is better than 45 heating/cooling cycles (1300°C - water); no change in linear and volume dimensions was observed on heating. The newly-developed castables can find application in various sectors of industry, in particular, as the refractory material for the lining of Whiting furnaces and porcelain kilns.

In view of its high mechanical strength and abrasiveness over a wide temperature range, SiC is used extensively in the production of silicon carbide refractorie.

Silicon carbide refractories have high physicomechanical properties and endurance, high mechanical strength, resistance to deformation at high temperature, and as a result of the absence of polymorphic transformations, it has a low linear thermal expansion coefficient (LTEC) and high thermal conductivity.

Silicon carbide refractories are mainly manufactured from granular semidry or plastic mixes by compaction, ramming, or stretching. In industry there is extensive use of silicon carbide based on silica, high-alumina, argillaceous and nitride binders.

Properties

1.The more SiC content, the better the alkali resistance

2.Silicon carbide in silicon carbide castables is especially advantageous at high temperatures (1100 ℃).

3.Produce partial gaps around the SiC particles to improve the thermal shock resistance and strength of the refractory castable.

4.The important chemical properties of silicon carbide are oxidation resistance, corrosion resistance, and the first reaction. When heated to 1000 ° C, the surface of SiC is oxidized and a SiC 2 film is formed. This film hinders the diffusion of oxygen, delays the oxidation rate, protects the silicon carbide covered by the film, improves the service life of the silicon carbide material.

5.Because the substrate is SIC, silicon carbide is wear resistant, silicon carbide has high hardness.

6.Silicon carbide is widely used in abrasives, heating elements, structural ceramics and refractory materials due to its high hardness, electrical conductivity, high temperature resistance and high strength.

Chemical & Physical Index

Silicon Carbide Refractories | |||||

Items | Unit | SiO2 Bonded Silicon Carbide Bricks | Azoxty-cornpounds Bonded Silicon Carbide Bricks | Mullite Bonded Silicon Carbide Bricks | |

Chemical Composition | SiC | % | ≤18 | ≤18 | ≥10 |

SiO2 | % | ≤8 | ~ | ~ | |

Fe2O3 | % | ≤1 | ≤0.6 | ≤1 | |

Al2O3 | % | ≥90 | ≥80 | ≥85 | |

Apparent Porosity | % | ~ | ~ | ≥10 | |

Bulk Density | g/cm3 | ≥2.56 | ≥2.60 | ≥2.56 | |

Cold Crushing Strength | Mpa | ≥80 | ≥100 | ≥70 | |

Refractoriness under Load | ℃ | ≥1600 | ≥1620 | ≥1550 | |

Thermal Shock Stability (Time/850) | ℃ | ≥40 | ≥40 | ≥35 | |

Thermal Conductivity | w/m*k | ≥8 | ~ | ~ | |

Normal Temperature Bending Strength | Mpa | ≥25 | ≥30 | ≥25 | |

High Temperature Bending Strength1250℃*1h | Mpa | ≥20 | ≥25 | ≥20 | |

Maximum Service Temperature | ℃ | 1400 | 1500 | 1400 | |

Material | Silicon carbide refractory castable | |||

Max working temp.(℃) | 1550 | 1650 | 1790 | |

Bulk density after drying at 110℃, g/cm3 | 3 | 3 | 2.95 | |

Chemical analysis, % | Al2O3≤ | 21 | 9 | 6 |

SiC+C≥ | 56 | 78 | 88 | |

Cold bending strength (Mpa) | 110℃*24H | 12 | 12 | 18 |

1100℃*3H | 15 | 15 | 20 | |

Cold crushing strength | 110℃*24H | 80 | 90 | 120 |

(Mpa) | 1100℃*3H | 100 | 120 | 135 |

Linear change after heating, % | 1000℃*3H | -0.2 | -0.1 | -0.2~0.2 |

1400℃*3H | -0.1 | -0.1 | -0.2~0.2 | |

Thermal conductivity, kcal/mh, ℃ | 8 | 11 | 12 | |

Water Addition | 7-8% | 6-7% | 6-7% | |

Construction method | Vibration | Vibration | Vibration | |

Application | Garbage incinerator | Nonferrous Metal Furnaces, Cement kiln & other Industrial Furnaces | Nonferrous Metal Furnaces, Cement kiln & other Industrial Furnaces | |

Characteristics:

l Corrosion resistance

l Good wear resistance

l High thermal conductivity

l High temperature strength

l Good thermal shock resistance

l Low thermal expansion coefficient

l Strong corrosion resistance

l Good anti-oxidation resistance

Application :

Our silicon carbide refractories are widely used in as lining of large aluminum electrolytic cell. The products can also employed to enlarge the tank capacity, enhance the thermal conductivity, alllow rapid cooling and boost up the tank production capacity at the same time. Alumina and cryolite of eutectic content on the surface can protect the tank lining work layer, prolong the tank's service life, therefore, silicon nitride bonded silicon carbide bricks is a welcomed product in aluminum industry.

Package

For Refractory Castables

1 ) . In 1MT Big Bag

2 ) . 25KG PP Big Bag In 1MT Big Bag

3 ) . customized packing as required

For Refractory Bricks

1 ) . Wooden pallet wrapped with plastic film and bundled belts.

2 ) . customized packing as required

Package

1 ) . In 1MT Big Bag

2 ) . 25KG PP Big Bag In 1MT Big Bag

3 ) . customized packing as required

Contact Us

- Henan Xinhongji Refractory Material Co. Ltd.

- Contact nameJacky Yan Chat Now

- Phone86-371-55611337

- AddressZhongyuan District, Zhengzhou, Henan

Product Categories

| Refractory Bricks | Refractory Castable | Raw Material | Refractory Ceramic Ball |

| Honeycomb Regenerator | Refractory Cement |

New Products

-

99% Alumina Content High Quality Refractory Corundum Castables

-

High Abrasion Resistant Fireclay Heat Insulation Castables Chamotte Insulating Castables

-

High Purity Aluminum Oxide Refractory Ball Thermal Insulation Ceramic Sphere Balls / Bead

-

High Temperature Resistance Calcium Aluminate Phosphate Refractory Binders High Alumina Refractory Cements

-

High Quality High Resistance Calcium Aluminate Secar High Alumina Refractory Cement

-

High Temperature Fine Powder Spinel Refractory Mortar for Lining Refractory Bricks

-

High Thermal Conductivity Silicate Carbon SiC Refractories Silicon Carbide Refractory Bricks

-

High Quality High Resistance Calcium Aluminate Secar High Alumina Refractory Cement

-

Al2O3 Content High Alumina Fire Proof bricks Insulating Firebricks Refractory Bricks

-

99% Alumina Content High Quality Refractory Corundum Castables

-

Lightweight Mullite Bricks Thermal Insulation Fire Resistant K23 ~ K32 Insulating Firebricks

-

Fire Proof High Alumina Thermal Insulation Powder Refractory Castable Low Cement Castable

-

Competitive Price Electro-melting Pink Fused Chrome corundum Grit Abrasive Aggregate Raw Material

-

Clay Refractory Brick Insulation Fire Clay Bricks SK23~SK34 Various Insulating Fireclay Bricks

-

High Density Aluminium Oxide Refractory Ceramic Sphere Ball Mill Grinding Ball / Bead

-

90% Al2O3 Content Refractory Sphere High Alumina Cenosphere Beads Corundum Ceramic Balls

-

1800 Centigrade Furnace Kiln Insulating Hollow Sphere Ball Refractory Alumina Bubble Bricks

-

High Quality Calcined Kaolin Aggregate Raw Materials for Refractory Brick Castable

-

Wholesale High Performance Magnesium Magnesite Refractory Bricks Magnesia Firebrick for Industrial Furnaces Kilns

-

Factory Price AZS Blocks Fused Alumina Zirconia Silica Corundum Bricks for Glass Furnace

-

Top Quality High Alumina Ceramic Refracotry Thermal Insulation Honeycomb Heat Regenerator

-

Factory Price High Temperature Proof Silica Bricks Refractory Brick for Hot Blast Furnace

-

Low Cement High Thermal Insulation Shock Resistant Stability Corundum Mullite Refractory Castables

-

Long Service Life High Strength High Alumina Refractory Corundum Mullite Bricks

Popular Searches

- refractory brick

- Fire Brick

- Mullite Brick

- Lining Brick

- ceramic filter

- ceramic plate

- insulating brick

- ceramic disc

- sic

- Sic Heater

- sic board

- silicon carbide plate

- sic brick

- silicon carbide tube

- ceramic bar

- silicon nitride plate

- bearing balls

- silicon nitride bearing ball

- Silicon Carbide Sic Brick

- Refractory Sic Brick

- building material

- refractory material

- floor tile

- refractories

- clay brick

- alumina brick

- Fire Brick

- ceramic filter

- fireproof material

- castable

Recommended Products

- fused cast zirconia corundum brick

- Glass kiln high temperature refractory material, the source manufacturer, China famous brand

- fused cast zirconia corundum brick

- fused cast zirconia corundum brick

- Magnesium oxide 90%

- Shandong supplier fiber reinforced calcium silicate board

- Placa de silicato de calcio 1000 * 500 * 50 mm

- High density thermal insulation material, high-temperature refractory lining

- High density calcium silicate board, carbon fiber, glass fiber

- High density non stick calcium aluminosilicate board

- Cement plant, power plant, aluminum plant, steel plant, chemical plant, metallurgical industry, thermal insulation board

- Chinese Shandong manufacturer calcium silicate insulation board

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Refractory Material > Special Refractory Material

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jacky Yan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Jacky Yan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile