Home > Products > steel rolling > Infrared Laser Cut-to-Length Cutting System

Infrared Laser Cut-to-Length Cutting System

- T/T Credit Card PayPal

You May Like

-

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)

-

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)

-

MAC-G320 Automatic Mold Flux Feeding Machine

-

MLC-V235 Continuous Casting Mold Level Automatic Measurement System

-

LDT-N200 Ladle Comprehensive Management System

-

LGK-S107 Analog Heat Source Instrument

Product Details

| Brand Name | ZFY | Place of Origin | China |

Product Description

Infrared/Laser Cut-to-Length Cutting System

Overview

The all-digital non-contact infrared automatic cut-to-length cutting system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-48 billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±1mm, and the system can support 12 strands high-definition CCD image measurement.

The features of the system

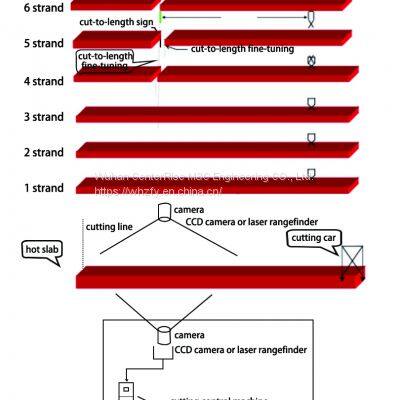

1. The system adopts advanced digital image processing technology (non-contact type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera.

2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-48 billets to length at the same time with an infrared camera.

3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1.

The functions of the system

1. Applicable to all kinds of continuous casting machine flame cutting system.

2. Adopt advanced digital image pickup technology.

3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding.

4. The system provides abundant interfaces, which can communicate with the PLC control.

5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting.

6. Historical cutting data is automatically stored, and the system can set rules for historical data.

7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose.

8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements.

9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters.

10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc.

11. Provide automatic, upper and manual cutting control.

12. The detection and cutting precision is high, and the controllable precision is ±3mm.

The extension of the system

The system can install 1 to 12 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 12 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy.

The technical parameters

1. Numbers of caster stands: maximum 12 strands

2. Measurement accuracy: ±1mm

3. Cutting method: flame cutting

4. Fixed length range: 6-12m

5. Matching casting speed: 1.5~4.2m/s

6. Fixed length range: 6-12m

7. Temperature range of cast products:<1000℃

8. Number of signals: pre-cut, cut

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact zero zero eight six one three nine nine five five eight eight five nine seven

Contact Us

- Wuhan CenterRise M&C Engineering CO., Ltd.

Product Categories

| continuous casting | steel rolling |

New Products

-

MDC-L200 Laser Taper Measuring Instrument (Multi-dimensional Detection)

-

CPL-N100 Square Billet/Round Billet Mold Surface Cladding Detection

-

ZST-P100 On-line Continuous Temperature Measurement of the Billet End

-

Mould Oscillation and Deflection Detection Instrument

-

LDT-L200 Ladle Lining Laser Thickness Gauge

-

SPD-V010 Handheld Roll Gap Checker

-

MDC-K120 Slab Mold Taper Measuring Instrument

-

MDC-K400 Square and Round Billet Taper Measuring Instrument

-

LAG-S100 Ladle Slag Detection System (Eddy Current)

-

SPD-V020 Multifunctional Strand Condition Monitor

-

LAG-S200 Ladle Slag Detection System (Vibration Type)

-

BPS-K600 Continuous Casting Mold Breakout System

-

Handheld Thermocouple Calibrator

-

WGS-L020 Flat Steel/Ribbon Iron Width Measuring System

-

LDC-X200 Laser Diameter Measuring System

-

CPC-D100 CPC Photoelectric Strip Automatic Center Position Control System

-

LAG-S400 Infrared Converter Slag Detection System

-

LDT-I200 Converter Lining Laser Thickness Gauge

Popular Searches

- production line

- cutting machine

- straightener

- plate shear

- metal cutting machine

- uncoiler

- decoiler

- machine line

- aluminium foil

- automatic machine

- slit machine

- straightening machine

- shearer

- slitter

- transformer equipment

- cut to length line machine

- decoiler machine

- recoiler

- combined line machine

- slit line

- combined line

- decoiler line

- uncoil line

Recommended Products

- Double-Column 10kN Universal Tensile Testing Machine with Servo Motor

- 10kn Universal Tensile Tester Tensile Testing Machine 10kn Longer Travel Space Computerized Electronic Universal Testing Machine

- Computer Control 10kn Electromechanical Universal Materials Mechanical Compression Properties Testing Machine

- 10kn Computer Control Universal Testing Machine 10kn Textile Elongation Computer Control Universal Testing Machine for Wire and Cable

- 50kn Electronic Tensile Tester Universal Testing Machine Compression Test Universal Materials Tensile Testing Machine

- 50kn Electronic Tensile Universal Testing Machine 50kn Computerized Model Wire Steel Universal Tensile Tester Testing Machine

- Computer Servo Universal Material Tensile Testing Machine Universal Testing Machine Supplier Tension Testing Equipment Ultimate Tensile Machine

- Automatic sampler Introduction of Bamtone/S275 products

- UL94 Horizontal Vertical Combustion Chamber | Flammability Test Equipment for Cable and Plastic

- Horizontal Vertical Burning Tester | UL94 Fire Resistance Test Equipment for Polymers

- UL94 HB V-0 Horizontal Vertical Flame Tester | Flammability Resistance Testing Equipment

- Horizontal Vertical Flammability Testing Machine | UL 94 Standard Combustion Test Chamber

Find Similar Products By Category

- Instruments & Meters > Test Instrument > Test Machine

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile