Home > Products > steel rolling > LDC-X200 Laser Diameter Measuring System

LDC-X200 Laser Diameter Measuring System

- T/T Credit Card PayPal

You May Like

-

CPC-D100 CPC Photoelectric Strip Automatic Center Position Control System

-

LAG-S400 Infrared Converter Slag Detection System

-

LDT-I200 Converter Lining Laser Thickness Gauge

-

Infrared Laser Cut-to-Length Cutting System

-

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)

-

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)

Product Details

| Brand Name | ZFY | Place of Origin | China | |

| Model Number | LDC-X200 |

Product Description

LDC-X200 Laser Diameter Measurement System

Overview

The non-contact diameter measuring system, is mainly used in the measurement of the outer diameter of various wire rods, bars, wires and pipes. The system can detect the change of the diameter (outer diameter) of the measured object in real time under the high temperature state.

The working principle

The diameter measuring system takes the laser scanning method as an example. It adopts the probe imported from Japan, which can achieve an accuracy of plus or minus 2 microns in the range of 0.3 to 30 mm. The acquisition frequency reaches 2000 times/second. The probe uses a self-excited infrared light source, which overcomes the measurement problem in dim environments.

It adopts the measurement method of pulse parallel light scanning, and has a strong ability to resist the jitter of the measured object. (As shown in Figure 1) Since the shaking frequency of the measured object is much smaller than the scanning frequency, when the measured object A moves in the shakeable area, the measurement result will be able to ensure its accuracy because the time it blocks the beam does not change.

Figure 1: Probe Scanning Radiation Area

The detection principle is as follows

Figure 2: Working Principle

First, the crystal oscillator generates self-excited high-frequency pulses, which are sent to the comparator and the stepping servo motor respectively. The stepping servo motor drives the octahedral prism to rotate at a high speed, and reflects the infrared laser emitted by the laser generator to the convex lens A. It becomes parallel light, and then collects on the photosensitive element C through the convex lens B in the infrared receiving probe. The photosensitive element C converts this signal into a corresponding electrical signal and sends it to the other end of the comparator to compare with the original signal.

When there is no object to be measured in the measuring probe, the pulse signal at both ends of the comparator will be the same. Therefore, there is no difference output: when there is an object to be measured in the measuring probe, the photosensitive element C will output no pulse signal during the period of scanning through the object to be measured. Therefore, there will be a difference input for a period of time at both ends of the comparator, which corresponds to the diameter of the measured object. By calculating the oscillation period of the pulse and the length of the time slice without pulse, the diameter of the measured object can be known.

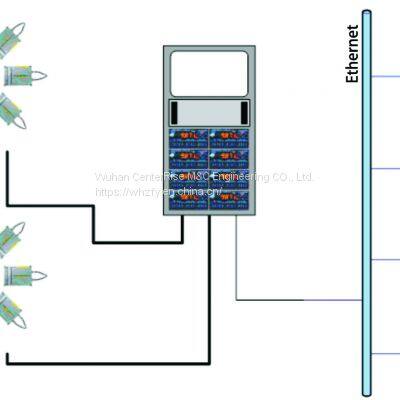

The composition and functions of the system

The system consists of the following main parts (as shown in Figure 1)

1. A measurement frame with four pairs of high-frequency laser scanning probes and non-contact infrared thermometers is installed

2. Four intelligent signal processors connected with four pairs of high frequency laser scanning probes

3. Cold air blowing system for cooling and cleaning the measuring frame

4. High-performance intelligent controller responsible for front-end data signal processing and network communication

5. Data processing and analysis system installed with industrial grade PC, monitor and printer

The technical indexes

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact zero zero eight six one three nine nine five five eight eight five nine seven

Contact Us

- Wuhan CenterRise M&C Engineering CO., Ltd.

Product Categories

| continuous casting | steel rolling |

New Products

-

MAC-G320 Automatic Mold Flux Feeding Machine

-

MLC-V235 Continuous Casting Mold Level Automatic Measurement System

-

LDT-N200 Ladle Comprehensive Management System

-

LGK-S107 Analog Heat Source Instrument

-

MDC-L200 Laser Taper Measuring Instrument (Multi-dimensional Detection)

-

CPL-N100 Square Billet/Round Billet Mold Surface Cladding Detection

-

ZST-P100 On-line Continuous Temperature Measurement of the Billet End

-

Mould Oscillation and Deflection Detection Instrument

-

LDT-L200 Ladle Lining Laser Thickness Gauge

-

SPD-V010 Handheld Roll Gap Checker

-

MDC-K120 Slab Mold Taper Measuring Instrument

-

MDC-K400 Square and Round Billet Taper Measuring Instrument

Popular Searches

- digital tester

- resistance tester

- electrical instrument

- test instrument

- lab equipment

- analysis instrument

- laboratory instrument

- asphalt mixture mixer

- launch x431 master

- x431

- gloss meter

- resistance meter

- digital instrument

- dc load bank

- testing equipment

- testing machine

- battery load bank

- circuit tester

- impact tester

- lab instrument

- weather station

- gps receiver

- test equipment

- laboratory equipment

- electronic timer

- electronic meter

- electronic instrument

- electricity meter

- data collector

- experiment apparatu

Recommended Products

- Double-Column 10kN Universal Tensile Testing Machine with Servo Motor

- 10kn Universal Tensile Tester Tensile Testing Machine 10kn Longer Travel Space Computerized Electronic Universal Testing Machine

- Computer Control 10kn Electromechanical Universal Materials Mechanical Compression Properties Testing Machine

- 10kn Computer Control Universal Testing Machine 10kn Textile Elongation Computer Control Universal Testing Machine for Wire and Cable

- 50kn Electronic Tensile Tester Universal Testing Machine Compression Test Universal Materials Tensile Testing Machine

- 50kn Electronic Tensile Universal Testing Machine 50kn Computerized Model Wire Steel Universal Tensile Tester Testing Machine

- Computer Servo Universal Material Tensile Testing Machine Universal Testing Machine Supplier Tension Testing Equipment Ultimate Tensile Machine

- Automatic sampler Introduction of Bamtone/S275 products

- UL94 Horizontal Vertical Combustion Chamber | Flammability Test Equipment for Cable and Plastic

- Horizontal Vertical Burning Tester | UL94 Fire Resistance Test Equipment for Polymers

- UL94 HB V-0 Horizontal Vertical Flame Tester | Flammability Resistance Testing Equipment

- Horizontal Vertical Flammability Testing Machine | UL 94 Standard Combustion Test Chamber

Find Similar Products By Category

- Instruments & Meters > Test Instrument > Test Machine

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile