Home > Products > seamarkzm1 > ZM-R7830A Smart Optical BGA Rework Station

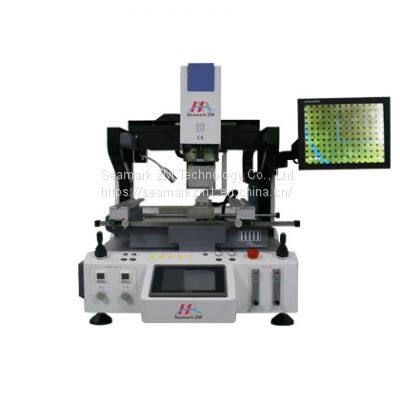

ZM-R7830A Smart Optical BGA Rework Station

- T/T

You May Like

Product Description

R7830A is an optical alignment automatic rework equipment. It also works as laser BGA SMD rework station, multi-language menu interface, automatic feeding device, X/Y AXI machine that can be controlled by joystick, fast and convenient operation, imported high-definition CCD (2 million pixels) optical alignment system, high Precision temperature control sensor system, precise temperature control.

As one of the most reliable BGA Rework Station manufacturers, Seamark ZM provides the best BGA machine for motherboards with good quality.

Functions of R7830A Laser SMD Rework Station

00 X/Y/Z Axis Automatic Displacement

The top temperature zone of the Laser SMD Rework Station is controlled by the joystick control servo system, which can automatically move and align at fast/slow speed by X/Y/Z Axis.

01 Vacuum Adsorption and Nitrogen Protection

The top heating head has a built-in vacuum suction nozzle for chip adsorption, electrically controlled 360-degree rotation alignment, with negative pressure monitoring and pressure protection device. The bottom temperature zone of the Laser SMD Rework Station adopts a large-area heating wire layout, moves symmetrically with the top temperature zone, and can be connected with nitrogen to prevent PCBA from yellowing.

Features of R7830A Laser SMD Rework Station

Multilingual menu interface

Automatic feeding device

X/Y axis can be controlled by joystick, operation is quick and convenient

Imported high-definition CCD (2m pixels) optical alignment system.

High-precision temperature control sensing system.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know some different types of BGA repair machines and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

Specification Of ZM R7830A Laser SMD Rework Station

Power Supply | AC380V±10% 50/60HZ |

Power | 7.15KW(Max), Top heater(1.45KW) Bottom heater (1.2KW), IR Preheater (4KW), Other(0.5KW) |

PCB Size | 565*467mm(Max); 6*6mm(Min) |

BGA Chip Size | 80*80mm(Max); 2*2mm(Min) |

IR Heater Size | 500*380mm |

Motion Control | X/Y/Z |

Temperature Sensor | 5 Pcs |

Operation Method | 8" HD touch panel |

Control System | Panasonic PLC + Temperature control module |

Display System | 15" HD industrial display ( 1080P 16:9) |

Alignment System | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator |

Vacuum Adsorption | Automatic |

Alignment Accuracy | ±0.01mm |

Temperature Control | K-type thermocouple closed-loop control with accuracy up to ±1℃ |

Feeding Device | Yes |

Positioning | V-groove with universal fixture |

Dimensions | L810*W1100*H960mm |

Weight | 151KG |

Seamark is a professional x ray inspection machine manufacturer. We provide china inline x ray machine, x ray pcb inspection machine, ir rework station and etc. Zhuomao has specialized in research, development, production, and sells superior quality BGA rework stations for more than 10 years.

Contact Us

- Seamark ZM Technology Co., Ltd.

- Contact nameJackie Tian Chat Now

- AddressBao'an, Shenzhen, Guangdong

Product Categories

| seamarkzm1 |

New Products

-

Offline X-Ray Inspection Machine

-

Online Reel Counter

-

Online X-Ray Inspection Machine

-

X5600 Offline X-ray Inspection Machine

-

ZM-R5860 Hot Air BGA Rework Station

-

ZM-R720A LED/Micro Component Rework Station

Popular Searches

- welding machine

- rework station

- bga rework station

- oven machine

- reflow oven

- bga rework system

- bga rework

- wave soldering machine

- pcb soldering machine

- steel mesh

- smt reflow oven

- bga repair system

- bga welder

- bga repair station

- bga welding machine

- laptop repair machine

- bga reballing machine

- bga repair machine

- soldering bga solder ball

- ic heater

- bga soldering system

- bga solder station

- laptop rework station

Recommended Products

- How to Obtain FCC Certification for a Robot Vacuum

- How to obtain FCC ID certification for a WiFi jammer

- The UL Report Process for Power Banks

- How to obtain FCC certification for floating lights?

- Application Process for an FCC ID for an Action Camera

- How do I obtain battery WEEE certification, and how long does it take?

- What is the difference between KC and KCC certifications in South Korea?

- How to Apply for CE Certification and Testing for Display Screens

- Do energy-saving lamps that have already obtained CE certification still need ERP energy efficiency certification?

- ?Bluetooth Speaker CE Certification Process

- Bluetooth Headset NBTC Certification Process

- CTA Network Access Permit Application Process and Required Documents

Find Similar Products By Category

- Service > Commercial Service > Other Commercial Service

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jackie Tian

Hi there! Welcome to my shop. Let me know if you have any questions.

Jackie Tian

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile